Carbonitriding process of pump shaft of automobile engine

An automotive engine, carbonitriding technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of low processing efficiency, unsatisfactory processing products, etc., to improve quality, improve hardness, The effect of reducing the quenching stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

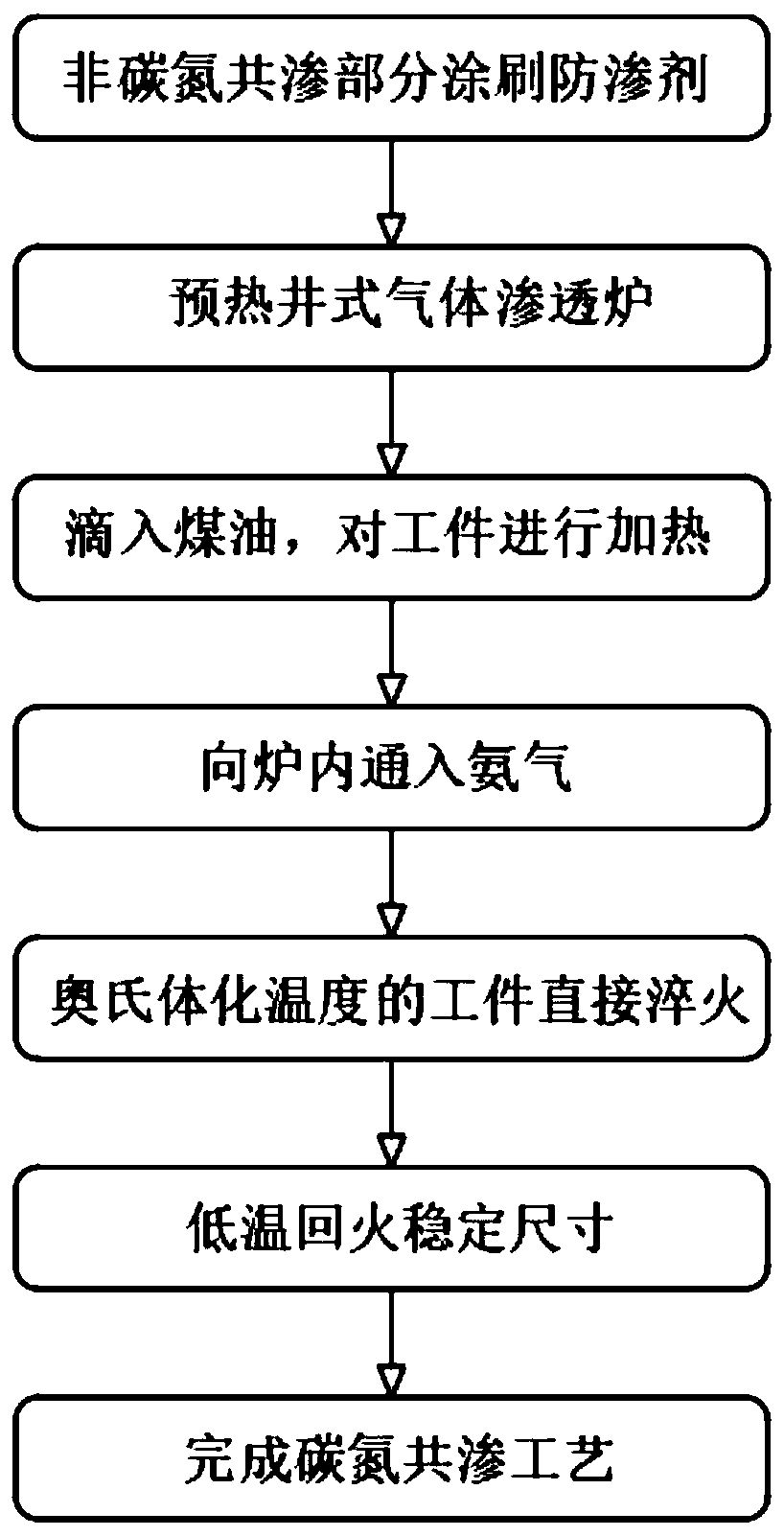

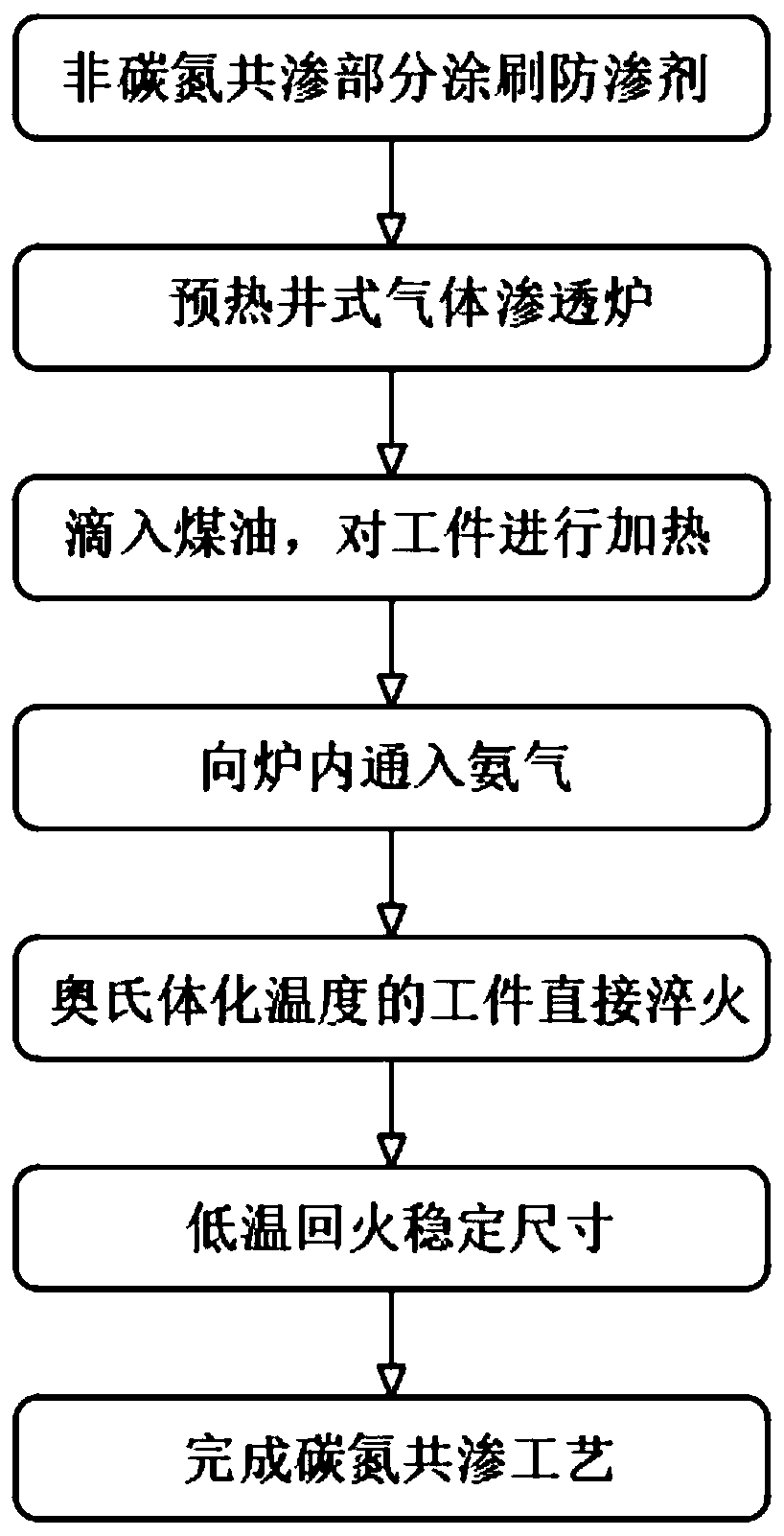

[0021] see figure 1 , an embodiment provided by the present invention: a carbonitriding process for an automobile engine pump shaft, comprising the steps of:

[0022] (A) Partially apply anti-seepage agent on the non-carbonitriding part, evenly brush the water-soluble anti-seepage agent on the top of the pump shaft of the automobile engine with a length of L1, and then let it dry naturally, and the air-dry time is 30-40min;

[0023] (B) Preheat the well-type gas carburizing furnace, and heat the well-type gas carburizing furnace to W1 for 10-20 minutes;

[0024] (C) Heating the workpiece. After the well-type gas carburizing furnace is preheated, drop 15-25ml of kero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com