Application method for X groove in thick-wall pipe high frequency induction welding

A technology of high-frequency induction welding and application method, which is applied to high-frequency current welding equipment, welding equipment, workpiece edge parts, etc. , The effect of solving the unstable welding quality and improving the welding production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

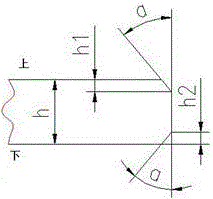

[0013] Embodiment 1: see figure 1 , a method for applying X-groove in high-frequency induction welding of thick-walled pipes, and a method for applying X-groove in high-frequency induction welding of thick-walled pipes. Mouth milling, 3) forming, 4) high-frequency welding.

[0014] The X-shaped groove edge milling in the step 2), the X-shaped groove is processed by the edge milling machine, and the full length of the edge milling machine is used for processing, the angle of the upper and lower grooves is a=30°~40°, and the upper and lower grooves Height h1 / h2=0.15t~0.35tmm.

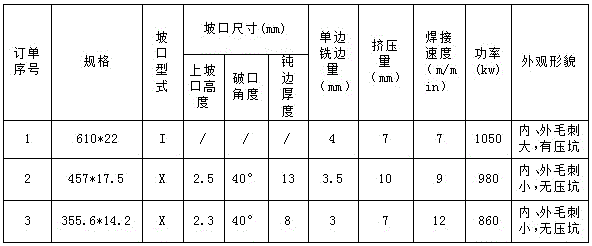

[0015] Specific application examples:

[0016] 1. In the production of φ610*22 and material 355J0H, I-groove high-frequency induction welding is adopted.

[0017] 2. φ457*17.5 / 355.6*14.2, material L415M adopts X-groove high-frequency induction welding. The process flow is loaded and uncoiled according to the conventional production method. The edge milling groove is set to be 40° up and down, the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com