Patents

Literature

99results about How to "Avoid affecting welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

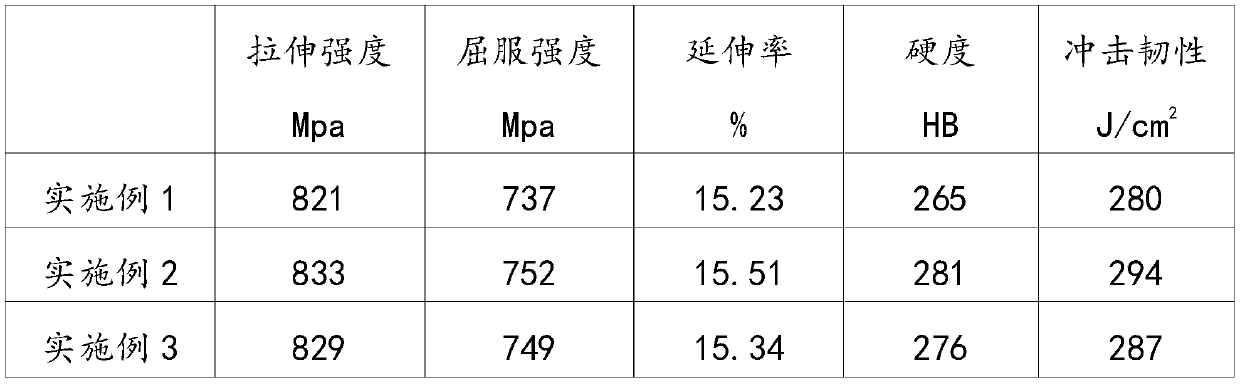

Preparation method of super-thick alloy steel plate

ActiveCN103692166AShorten welding timeAvoid Crack SensitivityWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyWelding joint

The invention belongs to the technical field of metallurgy and particularly relates to a preparation method of a super-thick alloy steel plate. The preparation method comprises steps that surface treatment is performed on two alloy steel continuous casting slabs matched in length and width dimension; the alloy steel continuous casting slabs are overlapped on a steel feeding swing arm of a tilting gear and align to each other; the alloy steel continuous casting slabs are fed into a vacuum chamber and welded through a structure with two electronic guns; when carbon equivalent of the continuous casting slabs to be compounded is smaller than 0.3%, a front electronic gun begins to perform welding from ends of the alloy steel continuous casting slabs, and a rear electronic gun begins to perform welding from middles of the alloy steel continuous casting slabs; when carbon equivalent of the continuous casting slabs to be compounded is higher than or equal to 0.3%, the distance between the two electronic guns is shortened, an electron beam of the front electronic gun is regulated into a defocusing mode, the front electronic gun preheats welding joints, and the rear electronic gun performs welding soon afterwards; heating rolling is performed on the welded slabs to obtain the super-thick alloy steel plate. By means of the technical scheme, compound interfaces between the continuous casting slabs to be compounded completely align, and yield of the super-thick alloy steel plate is increased.

Owner:沈阳科安捷材料技术有限公司

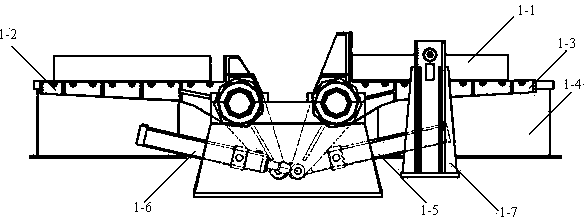

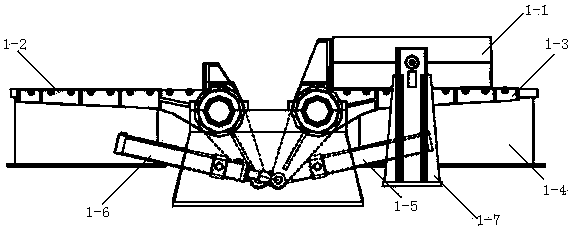

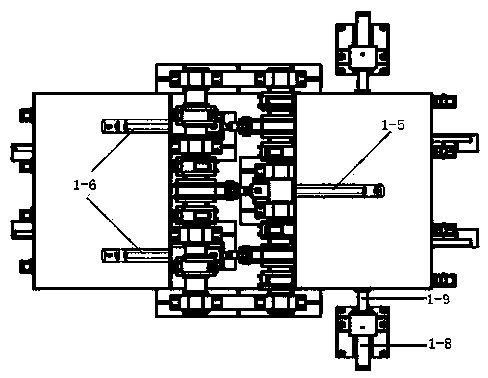

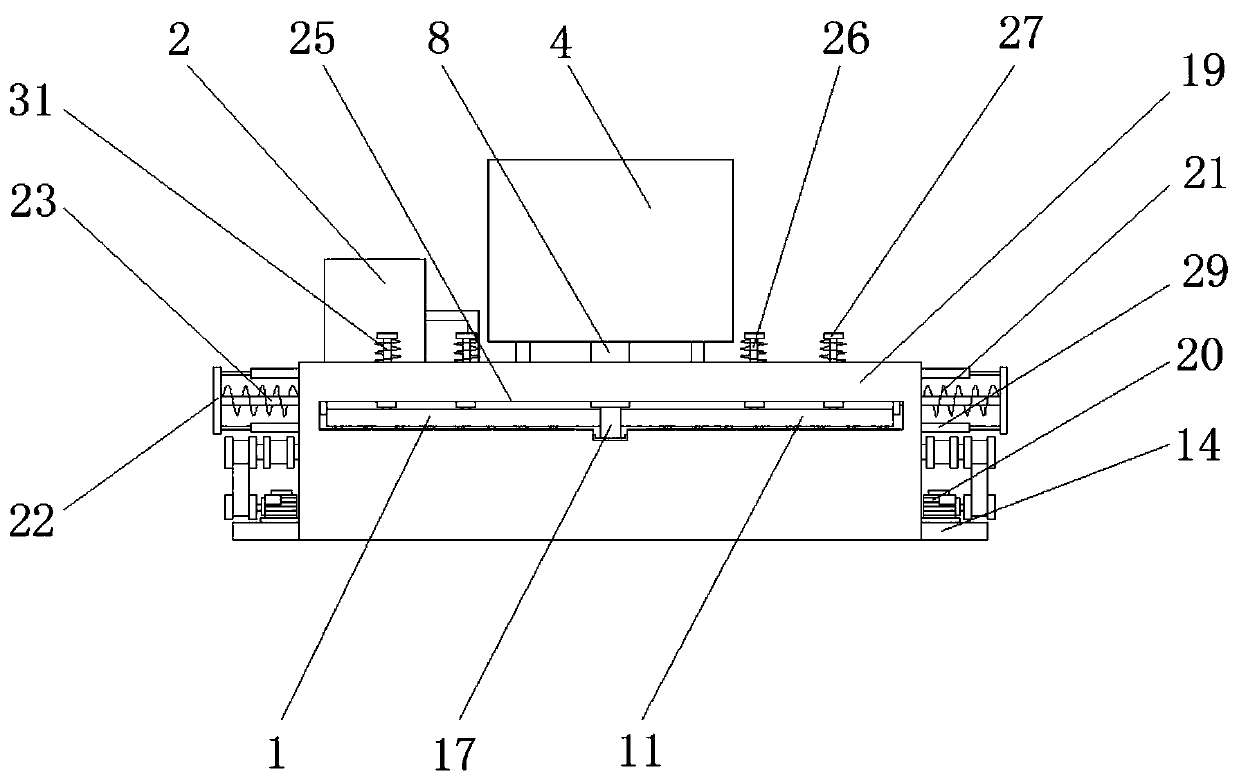

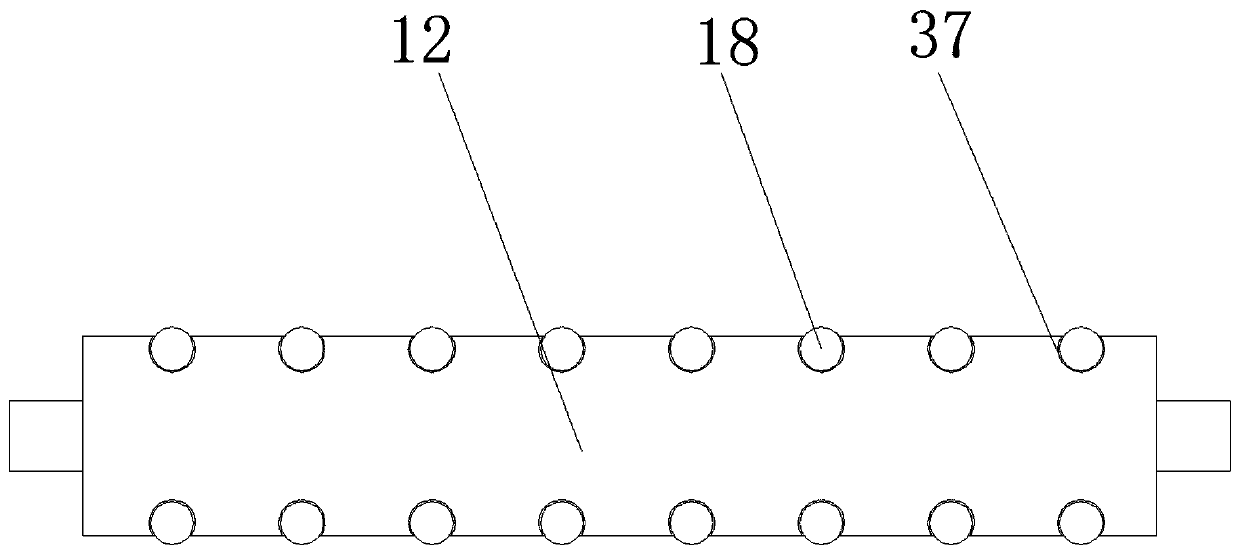

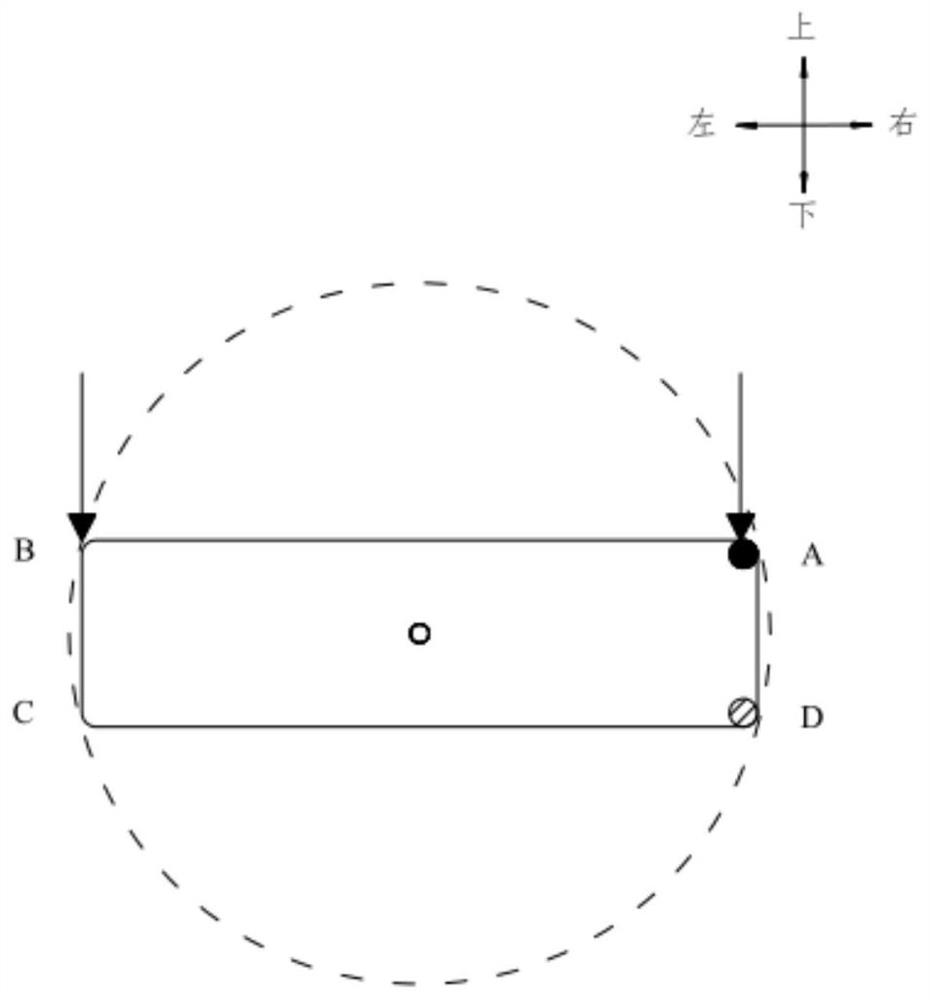

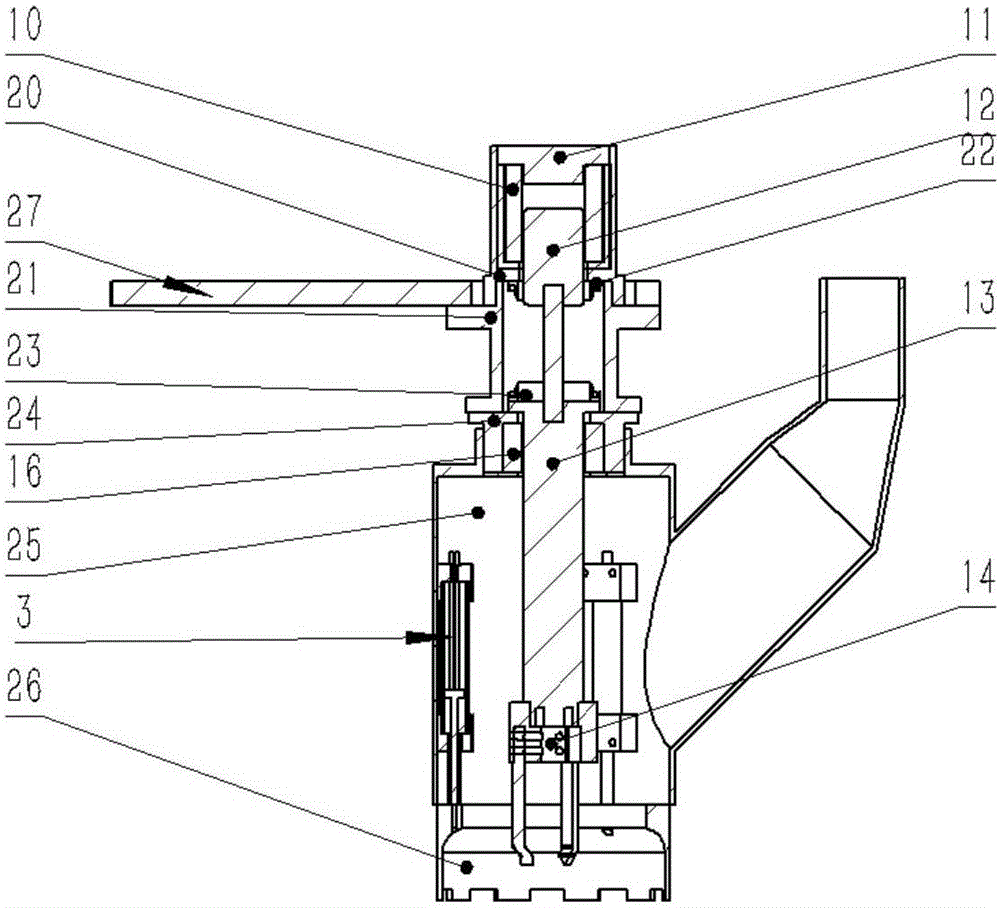

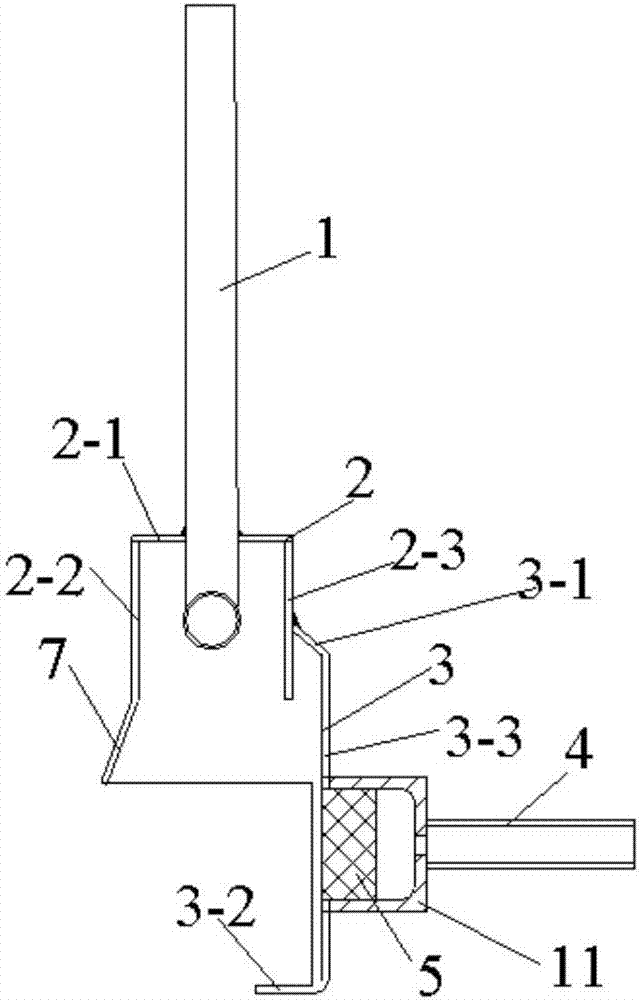

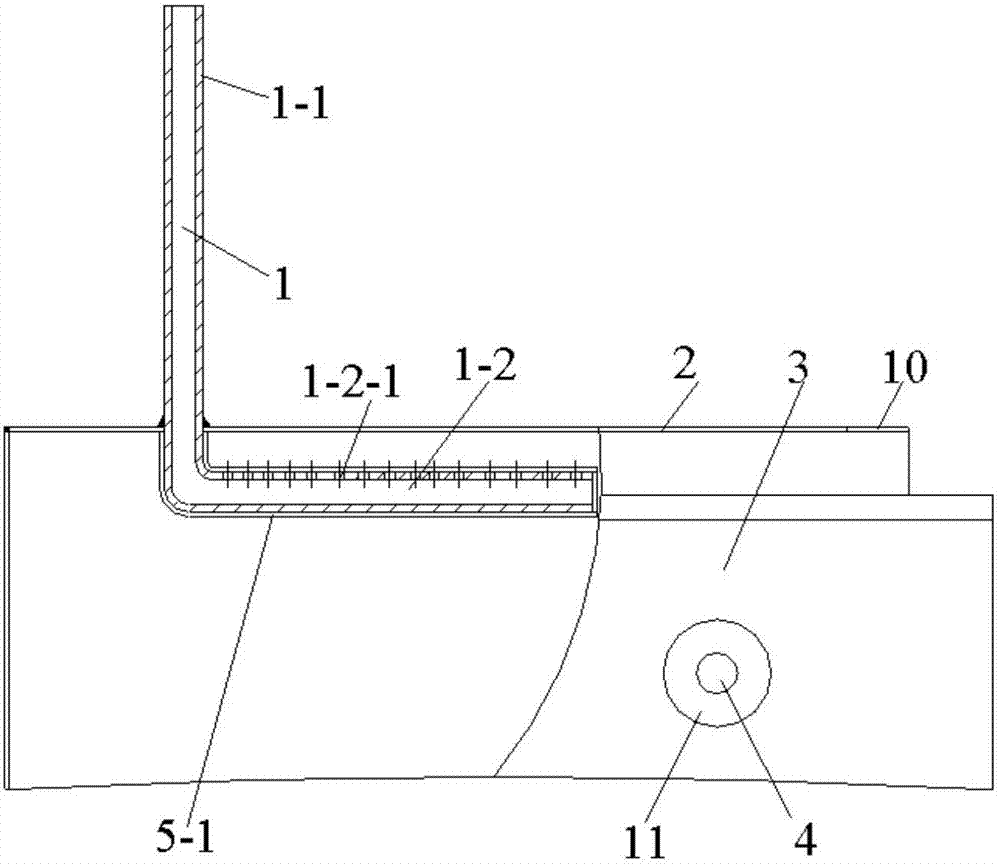

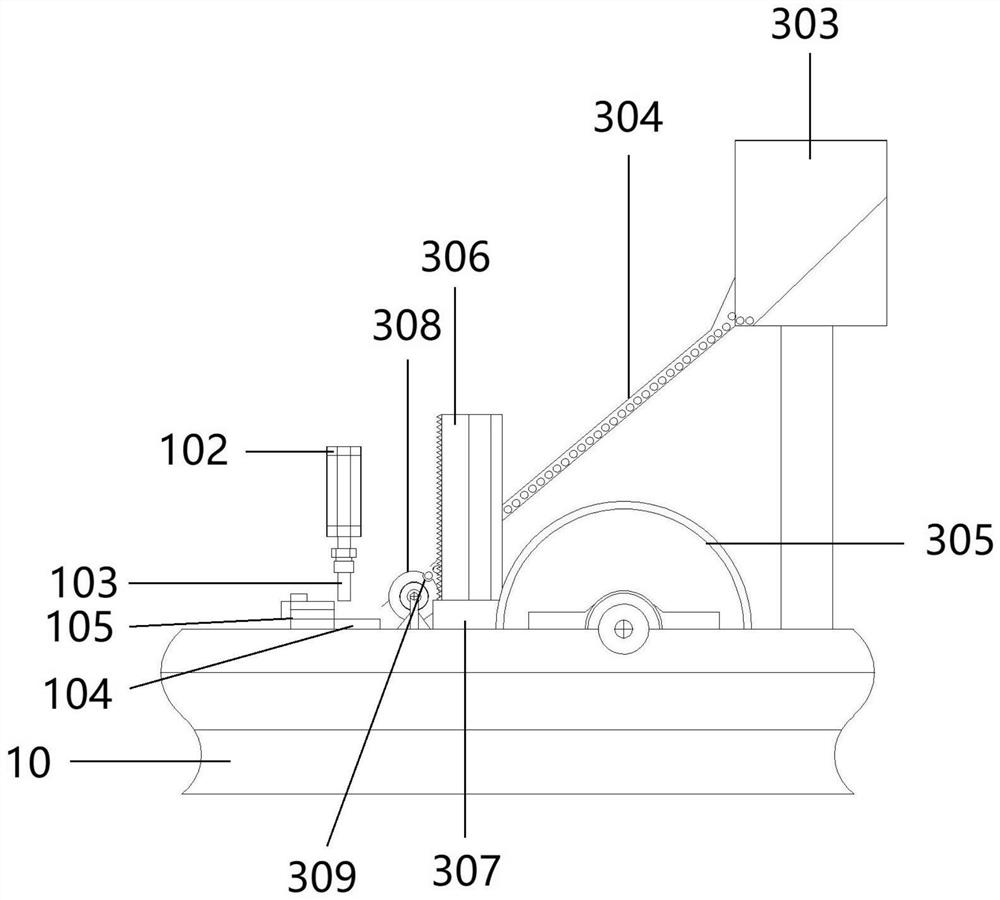

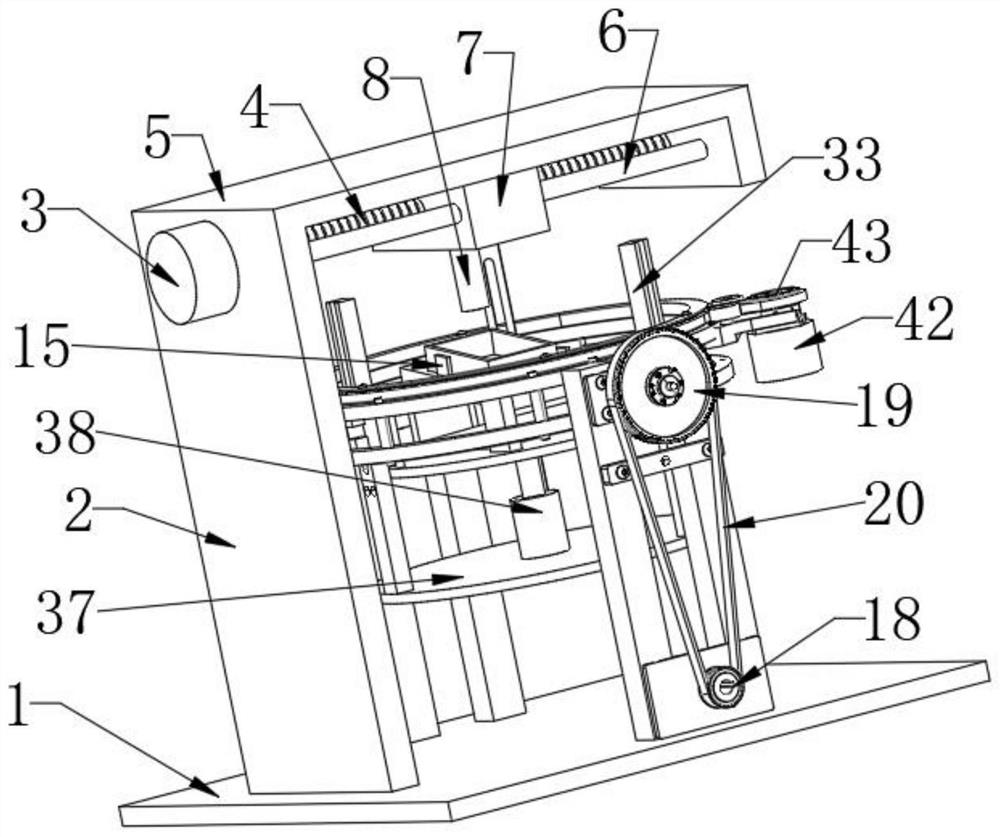

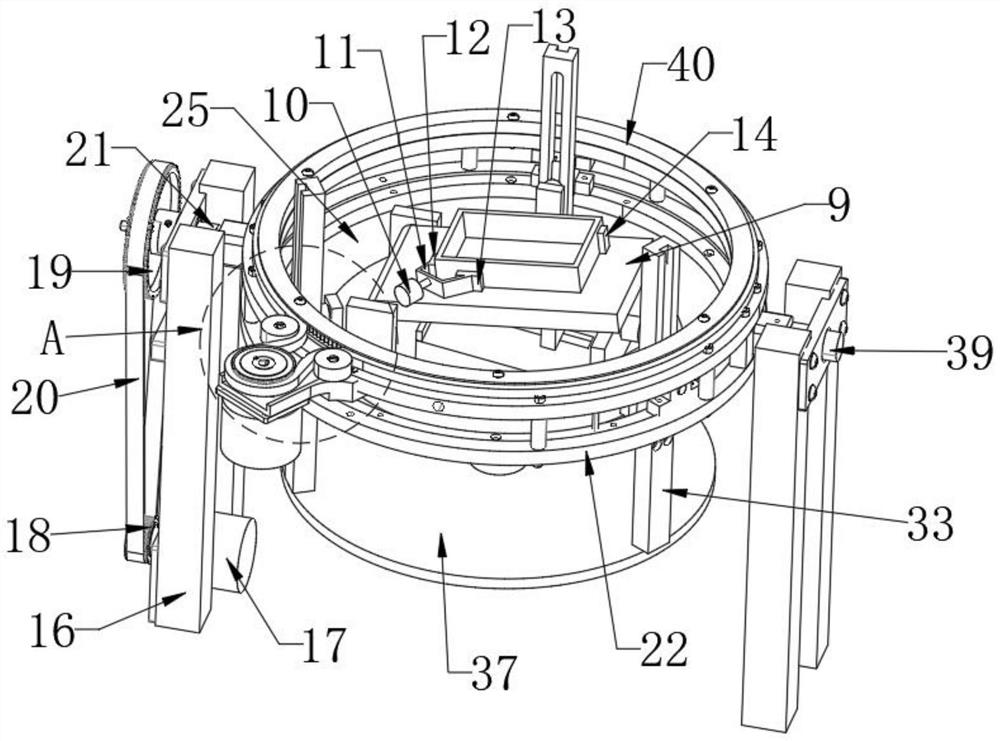

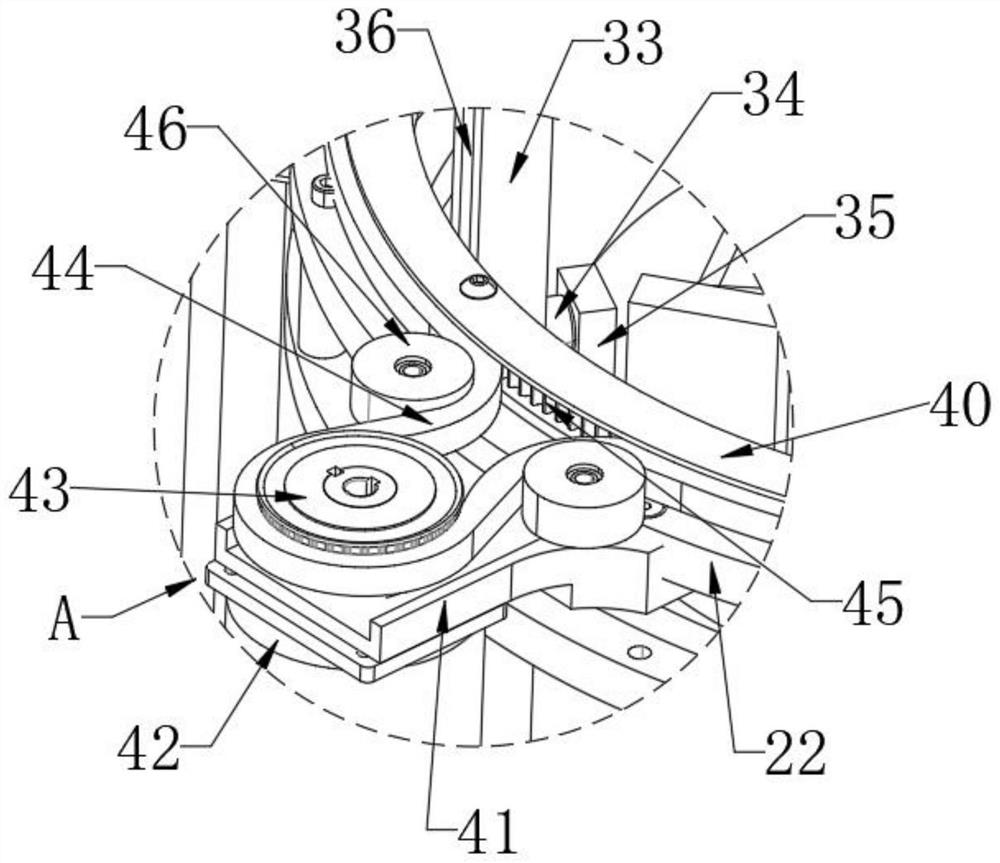

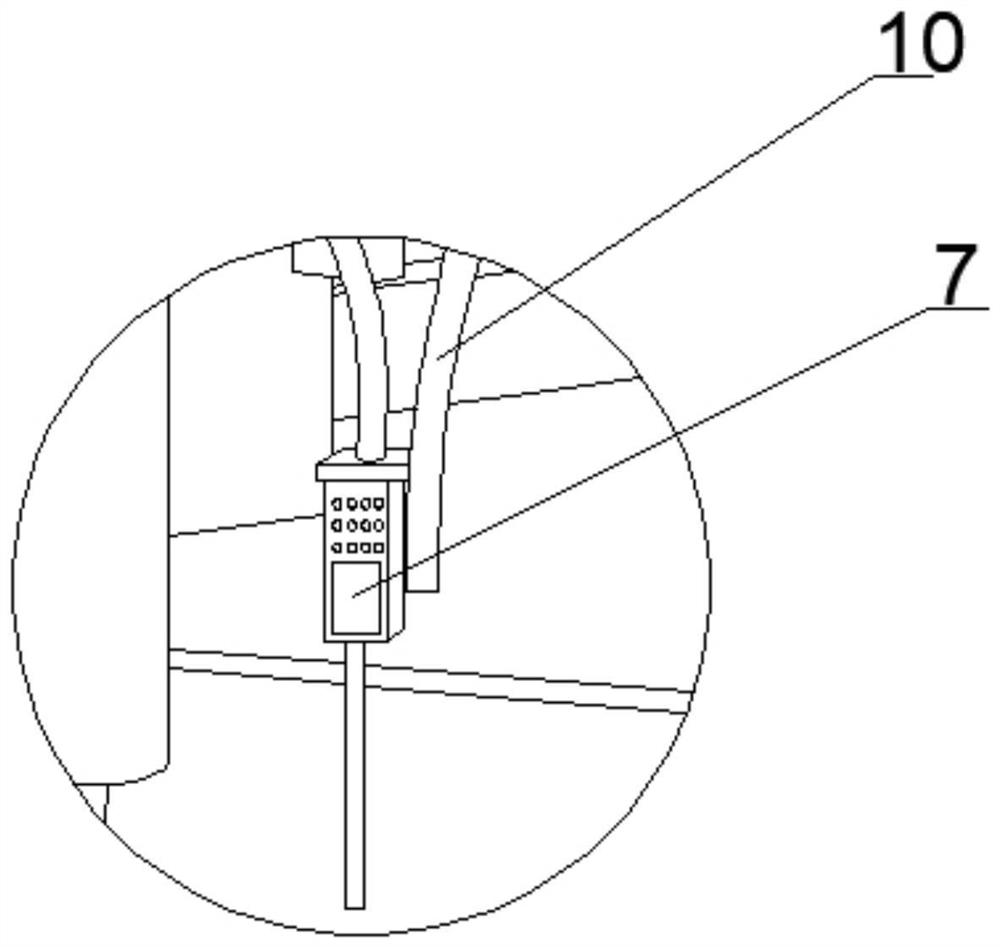

Internal circumferential joint welding device

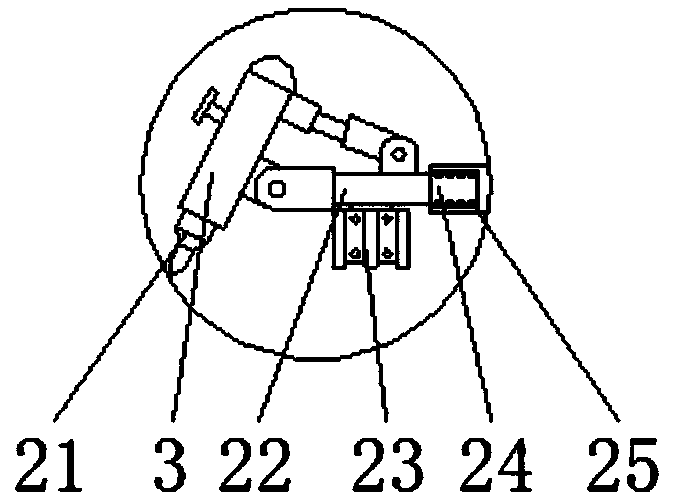

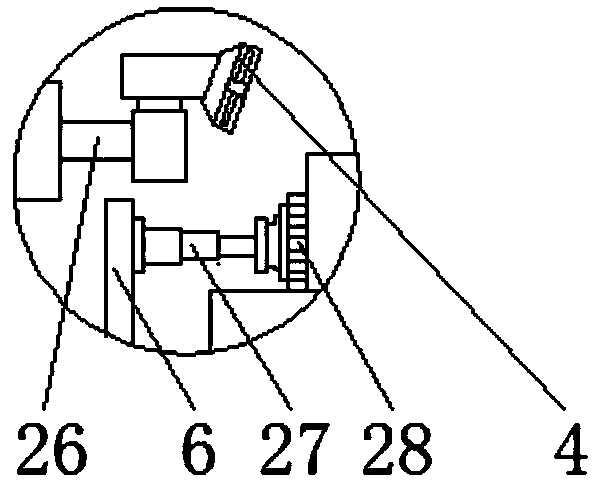

InactiveCN104625555AReduce adverse effectsGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

The invention provides an internal circumferential joint welding device and relates to the technical field of welding devices. The internal circumferential joint welding device comprises a lathe bed and a main shaft box which is arranged at one end of the length direction of the lathe bed and used for clamping a workpiece and driving the workpiece to rotate, a driving shaft is rotatably arranged on the main shaft box, the internal circumferential joint welding device further comprises a linkage device, a supporting device and a welding gun adjusting device, the linkage device is arranged at the bottom of the lathe bed and used for driving the lathe bed to tilt, the supporting device is arranged on the lathe bed and used for supporting the workpiece, and the welding gun adjusting device is disposed at the other end of the length direction of the lathe bed. According to the internal circumferential joint welding device, whole arrangement is simple, each device design is reasonable, internal circumferential joint welding requirements of various barrel workpieces can be met, welding qualities are good, the working efficiency is high, and defects that exist in manual welding can be effectively overcome.

Owner:杭州焊林科技有限公司

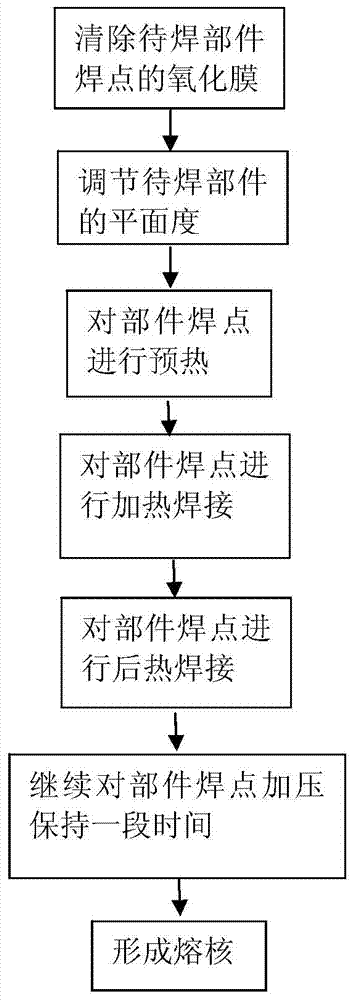

Resistance spot welding process for aluminium alloy parts

ActiveCN103692075AAvoid affecting welding qualityAvoid Solder Joint CrackingVehicle componentsWelding/soldering/cutting articlesMaterial resourcesSpot welding

The invention relates to the technical field of metal welding, and discloses a resistance spot welding process for aluminium alloy parts, which includes the following steps: (S1) parts to be welded are flattened in order to adjust the flatness of the parts to be welded; (S2) the parts to be welded are spot-welded, which includes the following steps: (S10) initial pressure is applied, so that the welding spots of the parts to be welded are in tight contact; (S20) a spot-welding machine is connected with welding current to preheat the welding spots of the parts to be welded; (S30) the welding current is increased to heat and weld the preheated parts to be welded, so that the welding spots of the parts are melted; (S40) the welding current is decreased to post-heat the parts; (S4) the spot-welding machine is disconnected from the welding current, and pressure is kept on the parts for a period of time, so that the welding spots are formed into nuggets. The welding process can reduce welding deformation, ensure the quality of the welding spots and prevent the phenomenon of welding spot cracking, thus increasing the quality of products, dispensing with the process of intermittent welding, saving manpower and material resources and increasing the efficiency of production.

Owner:CRRC QINGDAO SIFANG CO LTD

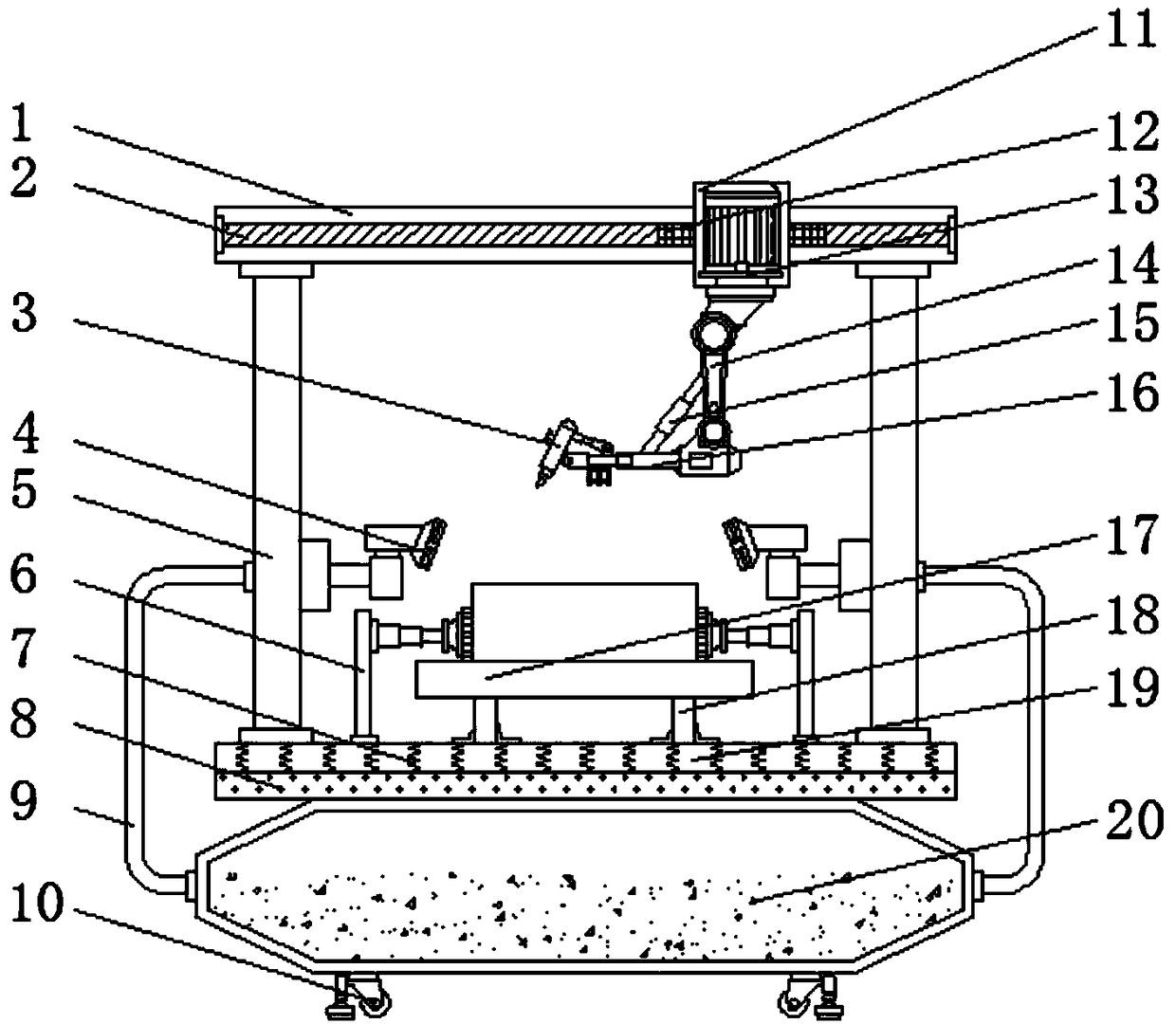

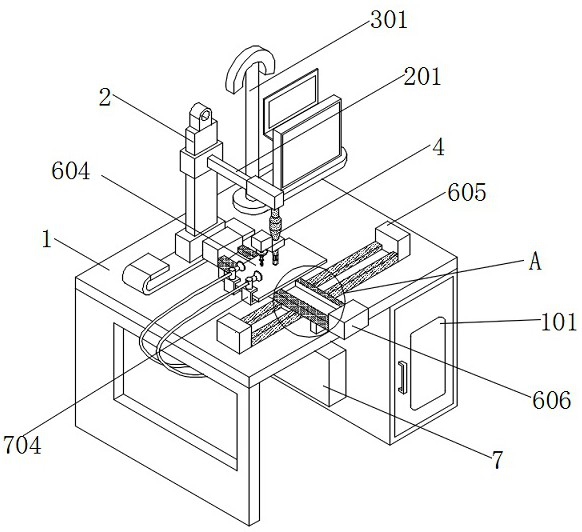

Intelligent welding robot

InactiveCN109015675AImprove adsorption capacityEasy to disassembleWelding/cutting auxillary devicesAuxillary welding devicesIdler-wheelWelding process

The invention discloses an intelligent welding robot which comprises a top plate, stand columns, a supporting base and a tank; a door body is installed on one side of the tank through hinge shafts; acontrol panel is installed at the end, away from the hinges, of the door body; a handle is installed on the side, away from the hinge shafts, of the control panel; idler wheels are installed at four corners of the bottom end of the tank; a supporting seat is welded to the top end of the tank; the stand columns are vertically installed at the two ends of the top of the supporting base; the top plate is installed at the top ends of the stand columns transversely; an electromagnetic sliding rail is arranged inside the top plate; a shell is installed on the electromagnetic sliding rail through a sliding block; and a motor is installed inside the shell. According to the intelligent welding robot, through installation of supporting rods, a hydraulic telescopic rod and clamping plates, products can be clamped and fixed conveniently before the robot performs welding, and the phenomenon that offset occurs in the welding process and consequently the product welding quality is affected is avoided.

Owner:合肥阅辞科技有限公司

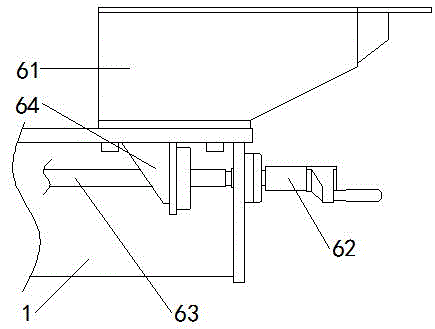

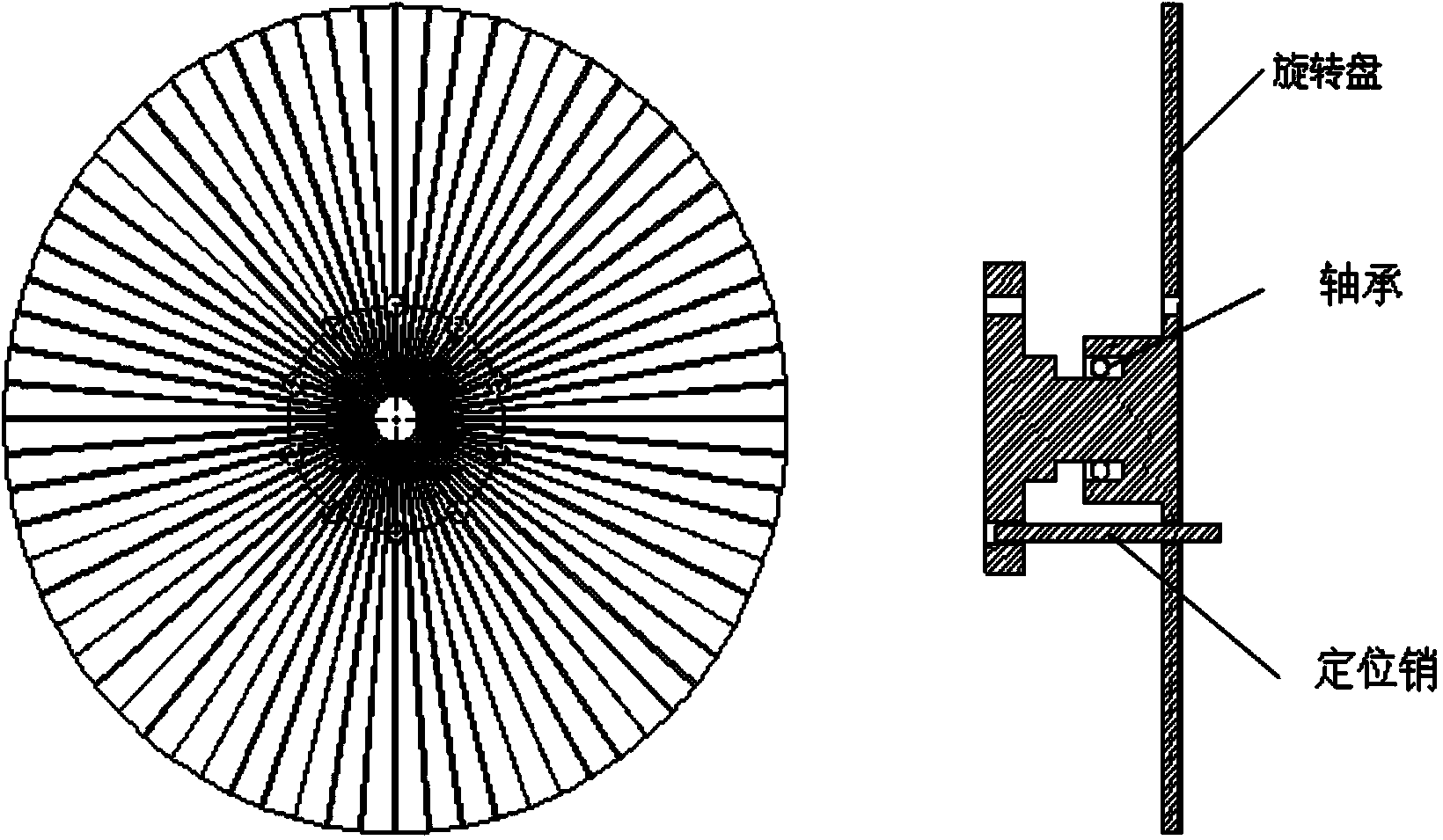

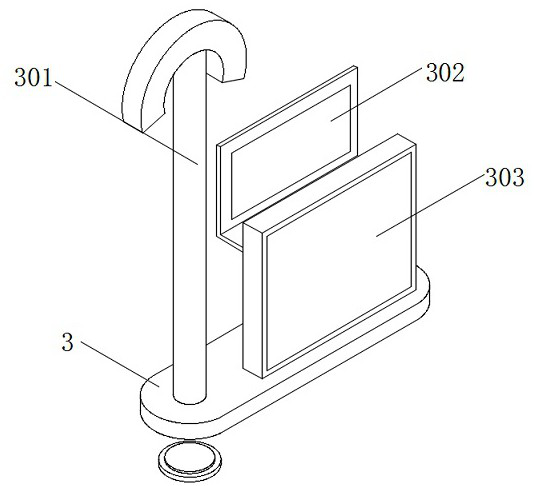

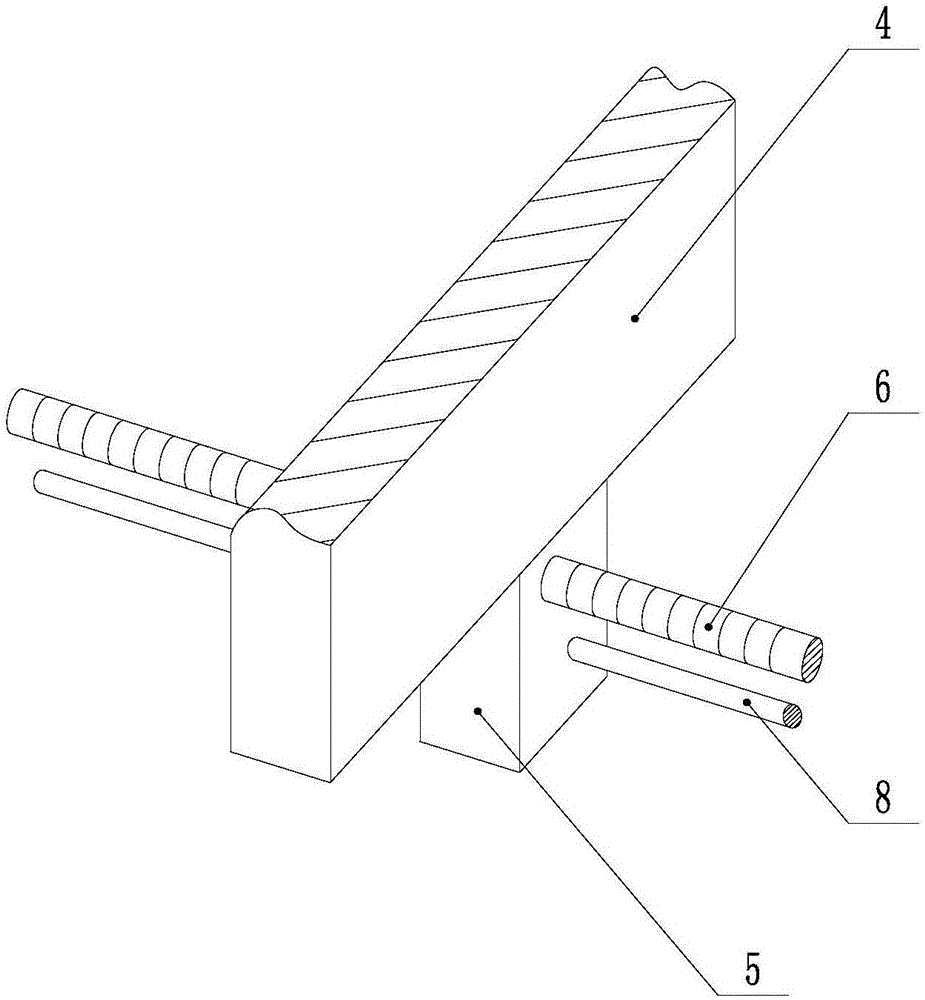

Four-way valve component pre-welding tool capable of general use

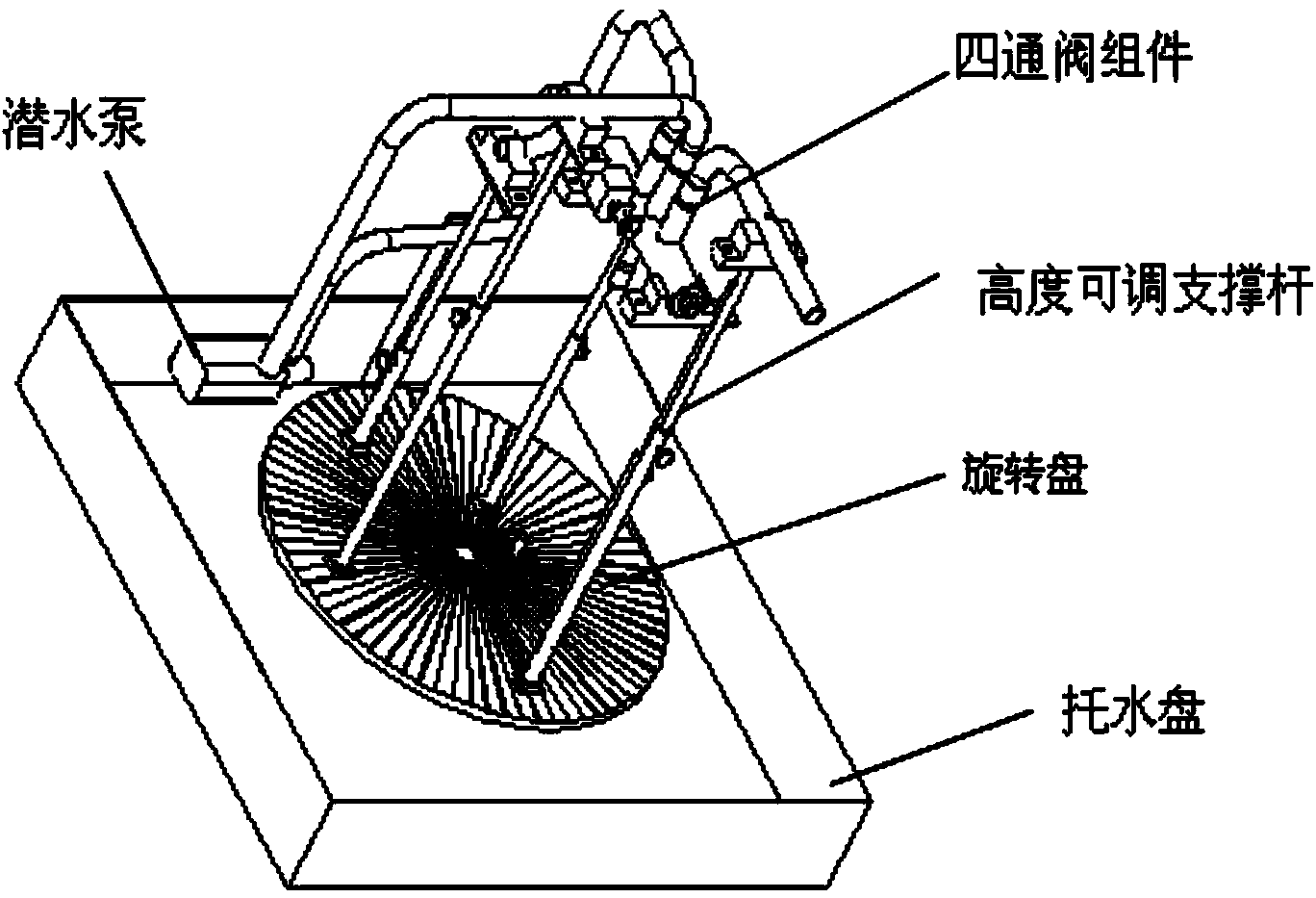

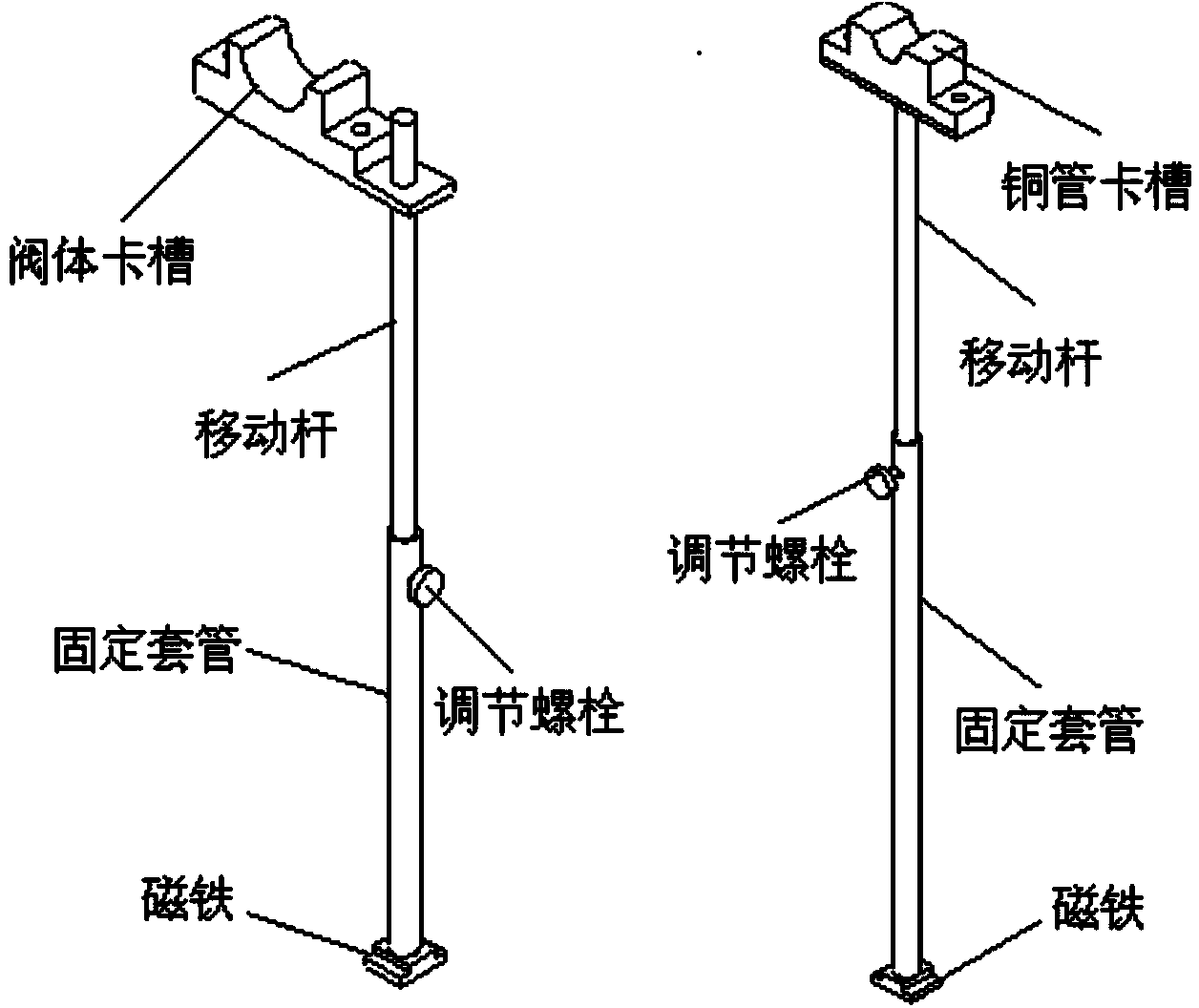

ActiveCN103521974AEasy to useEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesFour-way valveEngineering

The invention relates to a four-way valve component pre-welding tool capable of general use. The tool comprises a water carrying tray, a first adjustable supporting rod used for locating a four-way valve body and a second adjustable supporting rod used for locating a copper pipe, wherein clamping ends used for clamping welded objects are arranged at the top of the first adjustable supporting rod and the top of the second adjustable supporting rod, a rotating disk is installed in the water carrying tray, the rotating disk is fixed at the bottom of the water carrying tray through a bearing, a base of the first adjustable supporting rod and a base of the second adjustable supporting rod are placed on the rotating disk, the clamping end of the first adjustable supporting rod is a clamping groove of the valve body, the clamping groove of the valve body is detachable and matched with the four-way valve body, the clamping end of the second adjustable supporting rod is a clamping groove of the copper pipe, and the clamping groove of the copper pipe is detachable and matched with the copper pipe. The problems that an existing welding tool can not be applicable to four-way valve components different in size and is complicate in structure and not convenient to use are solved.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

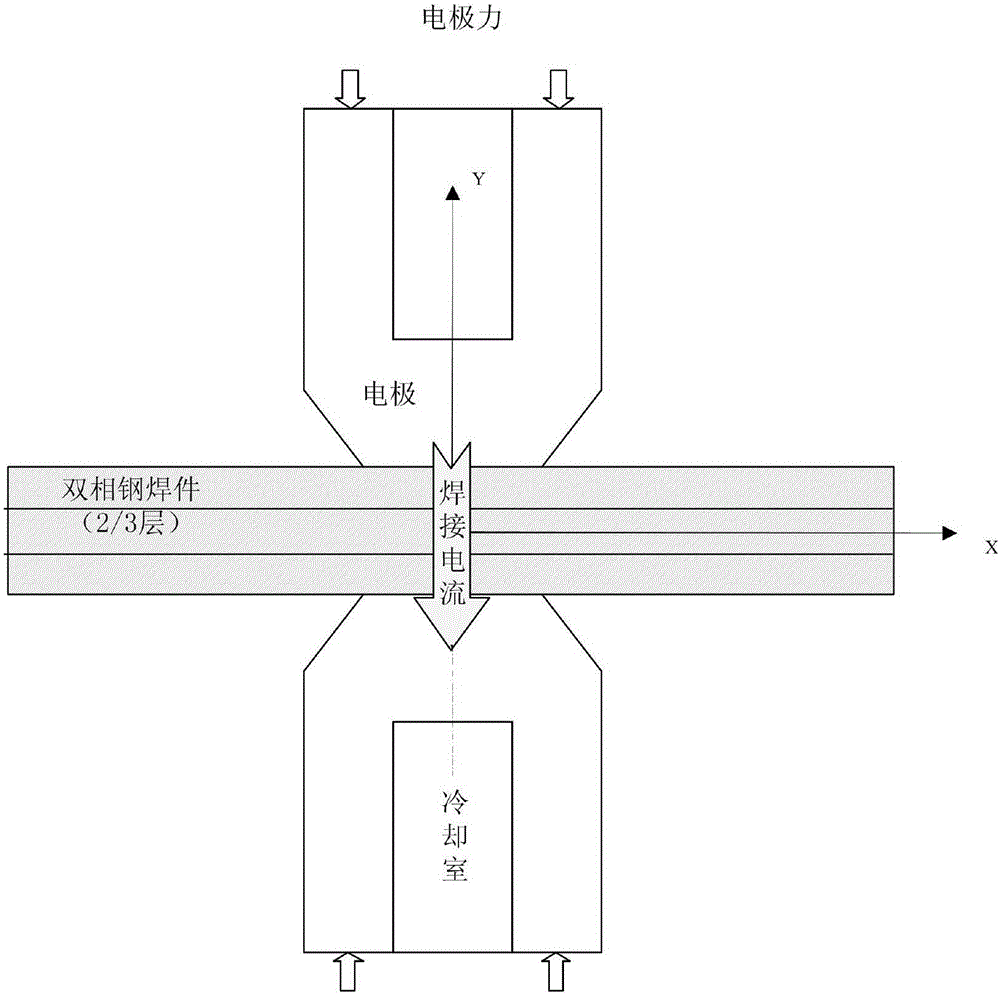

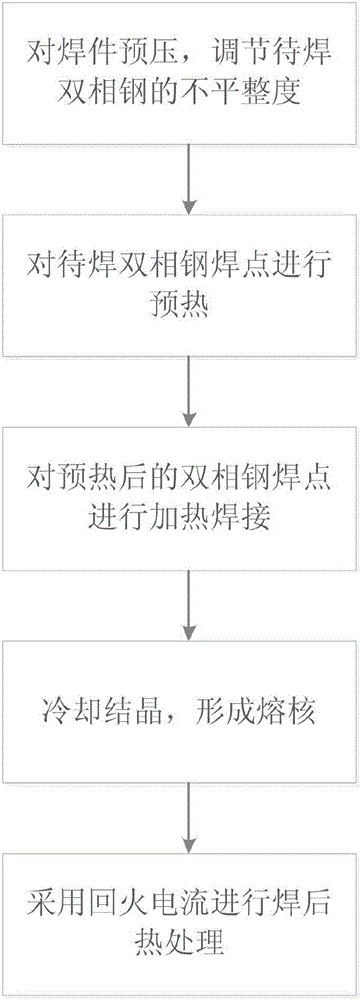

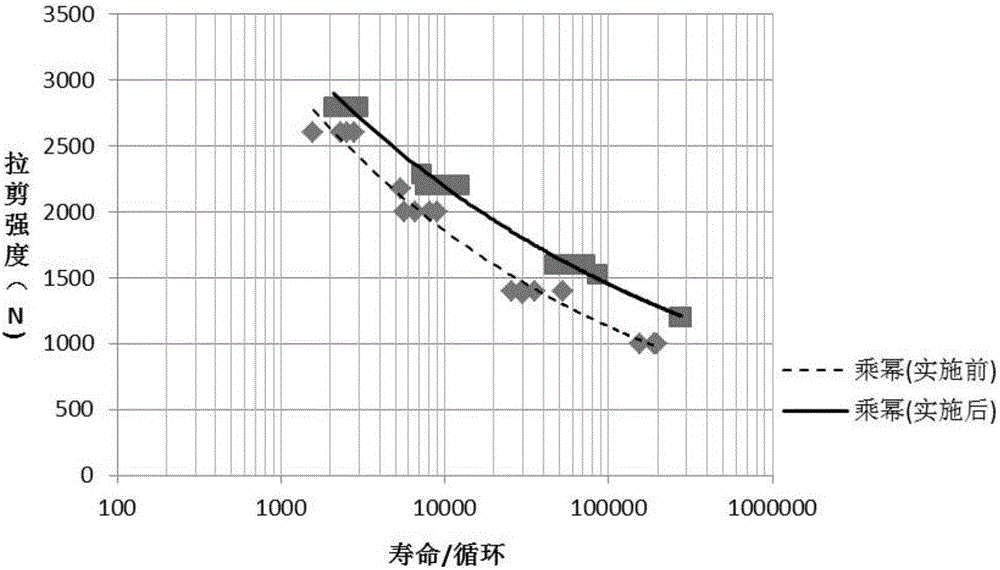

Resistance spot welding technology for improving quality of welding spots of dual-phase steel

InactiveCN106363288AAvoid affecting welding qualityPrevent shrinkageVehicle componentsWelding/soldering/cutting articlesMolten stateLiquid metal

The invention discloses a resistance spot welding technology for improving quality of welding spots of dual-phase steel. The resistance spot welding technology comprises the steps that firstly, the flatness of the to-be-welded dual-phase steel is adjusted to be 1 mm / m or below through pressurization; then, a spot welding machine is connected with a current to preheat the to-be-welded dual-phase steel; after preheating, the welding current is adjusted, and the to-be-welded dual-phase steel is subjected to heating welding; and the welding current is cut off, spot-welded joints quickly cool and form molten cores, and after the molten cores cool to the martensitic structure transformation temperature or below, a temper current is connected, and postwelding temper heat treatment is carried out. According to the resistance spot welding technology for the dual-phase steel provided by the invention, before welding, the flatness of the to-be-welded dual-phase steel is adjusted, spot welding is carried out through the manner of preheating-heating-cooling crystallization-tempering, and the problems that liquid metal in the molten state splashes and affects the welding quality and possibly causes unintentional harm to human bodies during the welding process are avoided; and besides, the welding spots are relatively stable during the welding process, the welding deformation is reduced, a brittle structure is changed, the quality of the welding spots is improved, the welding spots are prevented from having shrinking holes and cracks, and the quality of a product is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Welding method and clamp of Venturi tube with bend

ActiveCN102990265ASimple structural designMeet welding requirementsWelding/cutting auxillary devicesAuxillary welding devicesEdge surfaceEngineering

The invention discloses a welding method and clamp of a Venturi tube with a bend. The welding method comprises the steps of: respectively clamping and positioning an inlet section and an outlet section of a Venturi tube with a transition section for welding; sequentially spot-welding all spots on a butt seam corresponding to arcs of 0 degree->180 degrees->270 degrees->450 degrees->495 degrees->675 degrees; carrying out sealing welding along the clockwise rotation from the starting point of the butt seam, and after welding the butt seam for one circle, starting arc extinguishing in a place exceeding the starting point by 15 degrees, so as to complete the sealing welding; and selecting a point, between which and the starting point the arc angle is 180 degrees, as another starting point to perform welding, and after welding for one circle, starting the arc extinguishing in a place exceeding the starting point by 15 degrees, so as to complete the welding. The clamp comprises a center shaft with a bend, wherein an inlet inner sleeve and an outlet inner sleeve are sleeved on the center shaft, the outer edge surfaces of the inner sleeves are clung to the inner wall of the Venturi tube, and protection sleeves are respectively arranged on two ends of the inner sleeves, and clamping flanges are respectively arranged on opening ends of an inlet section and an outlet section and are fixed through nuts. According to the welding method and the clamp disclosed by the invention, the Venturi tube with a wall thickness of 1-3mm and the bend of 3-8 degrees can be welded.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Laser and arc composite welding method of martensite precipitation-hardening stainless steel

InactiveCN110293322AUniform weld formationReduce distortionLaser beam welding apparatusButt jointMartensite

The invention relates to a laser and arc composite welding method of martensite precipitation-hardening stainless steel. The method includes the steps that butt joint connection ports of two to-be-welded workpieces are machined into grooves; the two to-be-welded workpieces are assembled and fixed, and a gap is reserved between the two to-be-welded workpieces; laser is adopted for performing backing welding on the bottoms of the grooves, and bottom weld joints are performed; and laser and arc composite welding is adopted for performing wire filling and face covering welding on the grooves, anda welding process is completed. According to the method, due to the fact that the laser backing welding is firstly performed on the bottoms of the grooves formed after machining of the to-be-welded workpieces, penetration fusion welding is achieved, through welding of the bottom of a truncated edge can be guaranteed, so that the weld joints at the bottoms of the grooves are uniform in forming, deformation is small, and the welding precision is guaranteed; then laser-arc composite welding is adopted for performing wire filling and face covering welding on the grooves, and therefore the high-quality weld joints are formed; and work procedures are simple, operation is easy, the process cost is low, and a good welding effect is achieved on the special material of the martensite precipitation-hardening stainless steel.

Owner:WUHAN JINDUN LASER TECH CO LTD

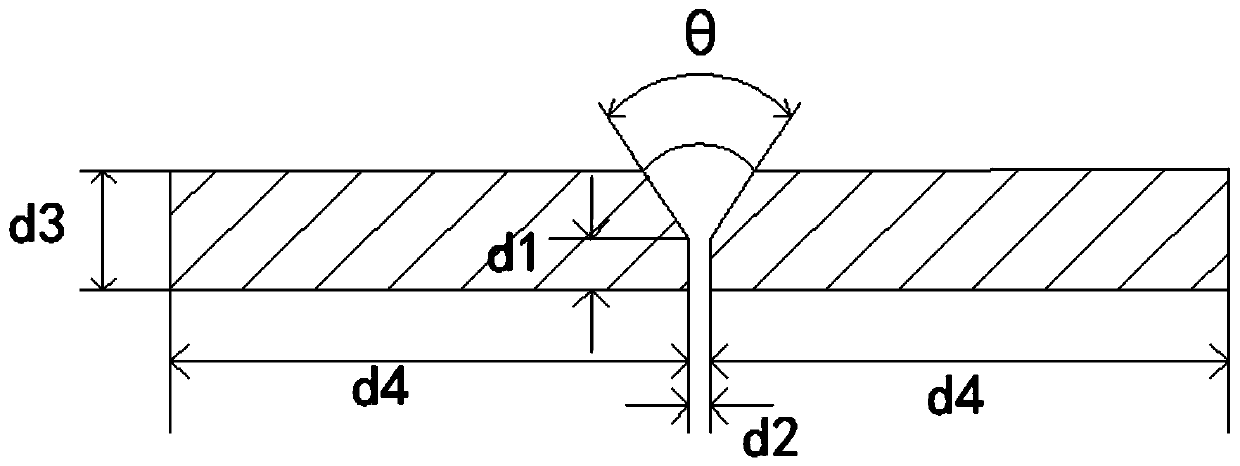

Laser transmission welding method for connecting plastic pieces

ActiveCN106273416AAvoid affecting welding qualityImprove heat transfer efficiencyHeat transfer efficiencyZinc alloys

The invention discloses a laser transmission welding method for connecting plastic pieces. The method is used for laser welding between a first plastic piece and a second plastic piece; a groove is formed in the second plastic piece, and is filled with zinc alloy powder or similar metal powder with low melting point and high heat conductivity to realize heat transfer, so that the heat transfer efficiency is greatly promoted, and the transmission welding of the same type of plastic pieces can be realized; and in addition, when the light emitting of a laser in unstable, the metal powder achieves an excellent transition effect to prevent influence on the welding quality by higher moment power.

Owner:SUZHOU UNIV

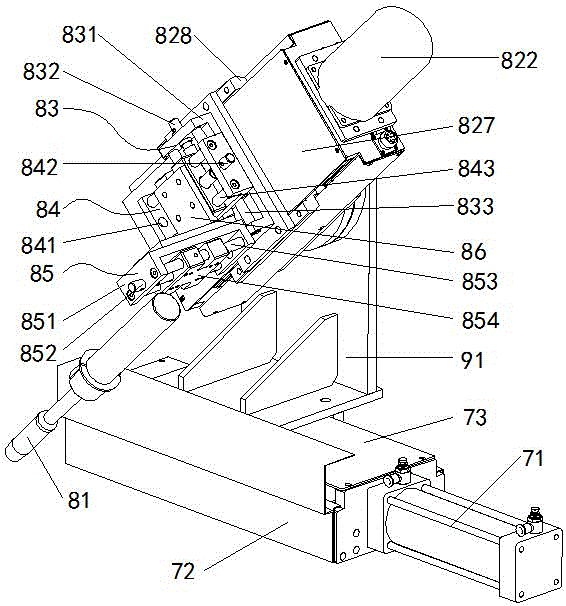

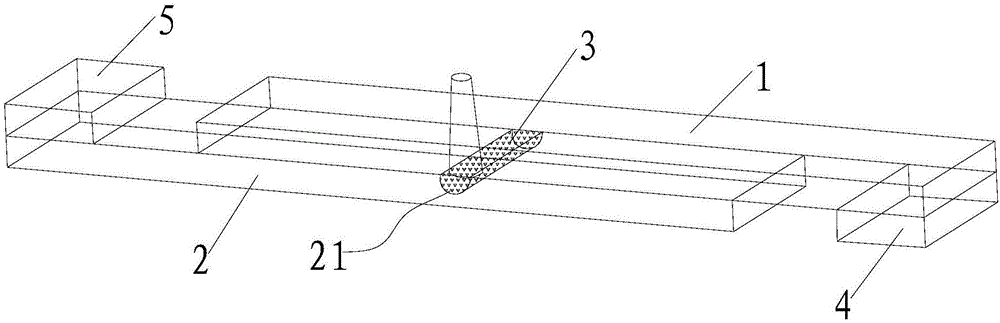

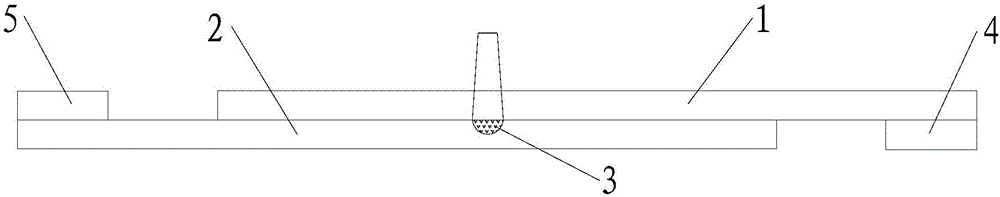

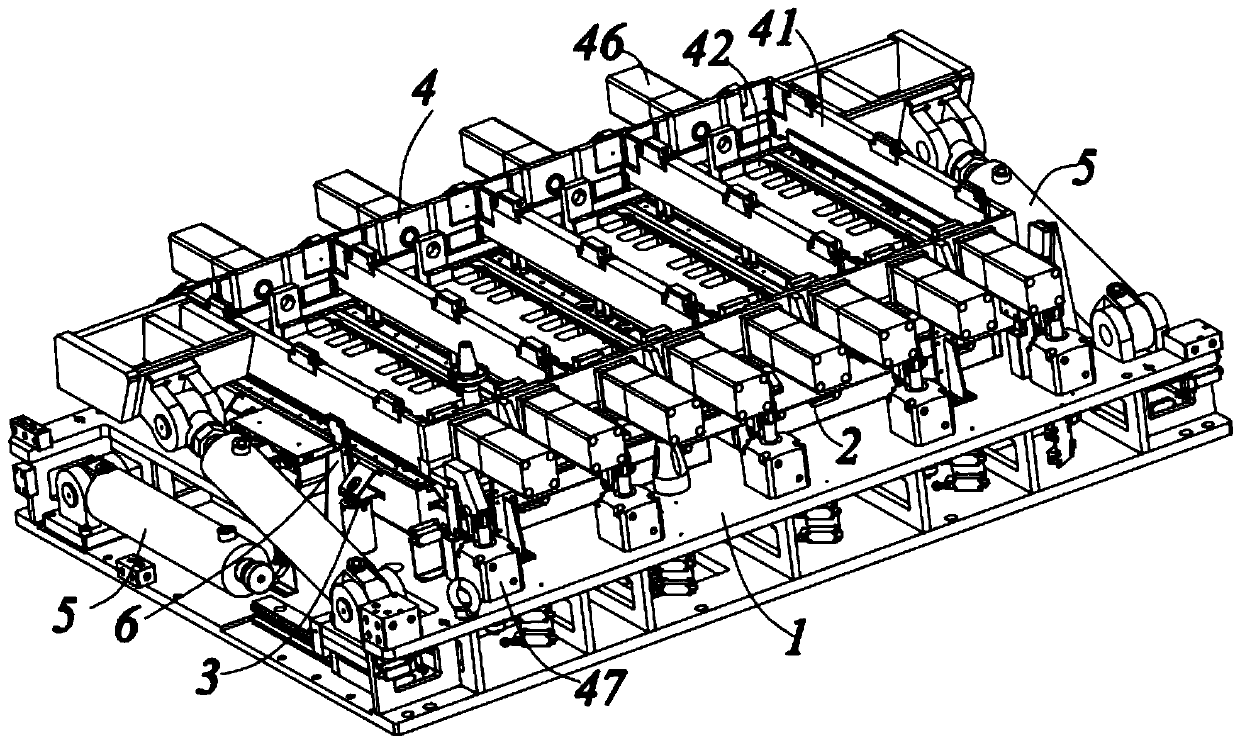

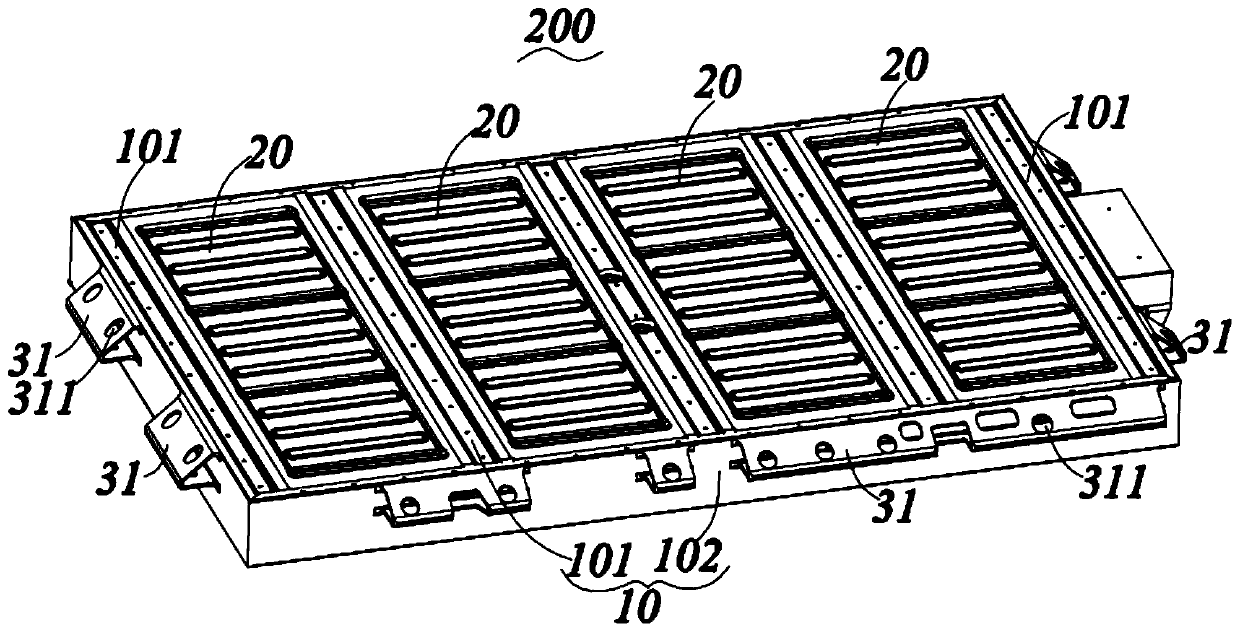

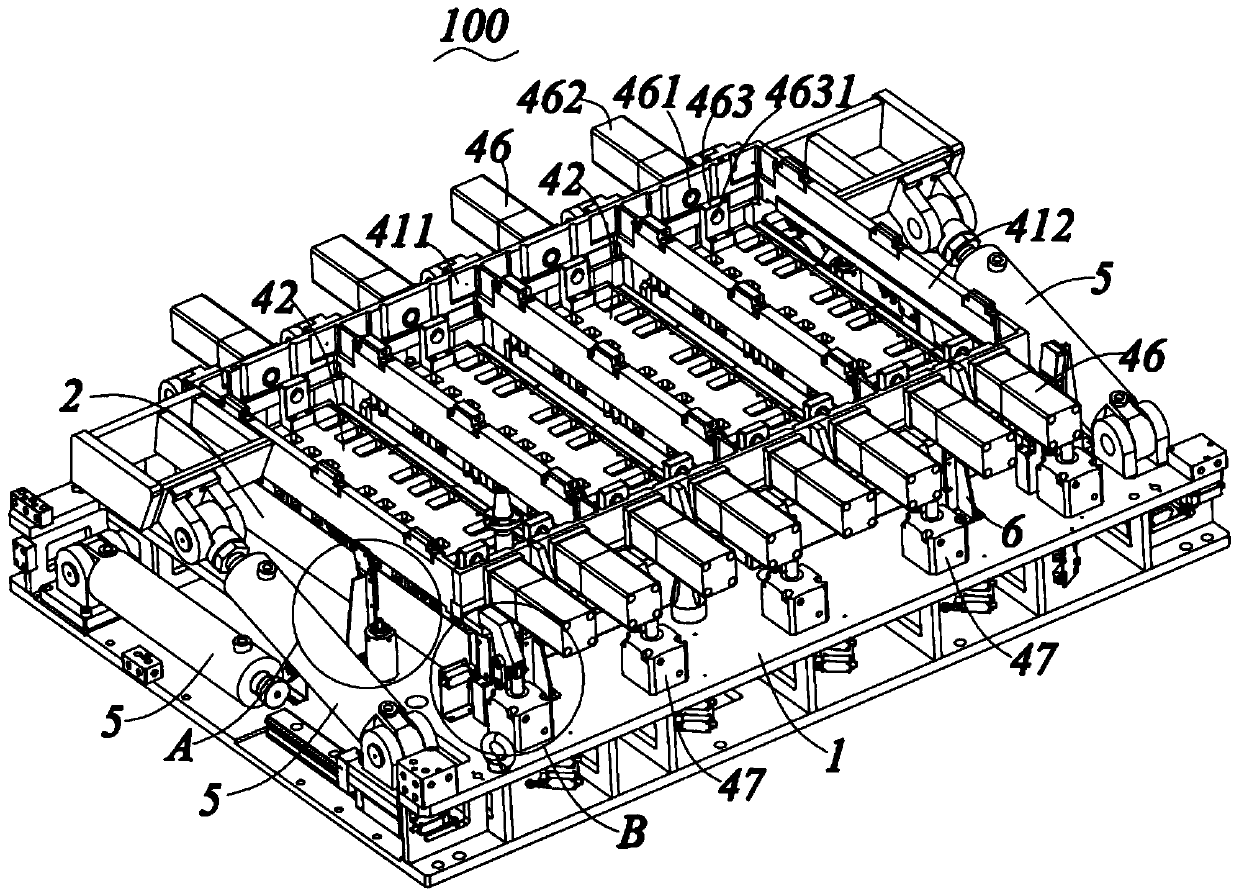

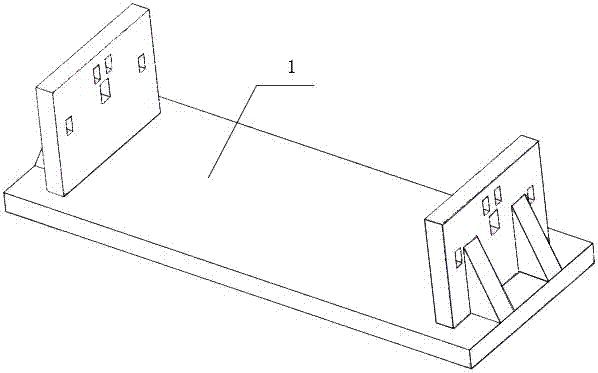

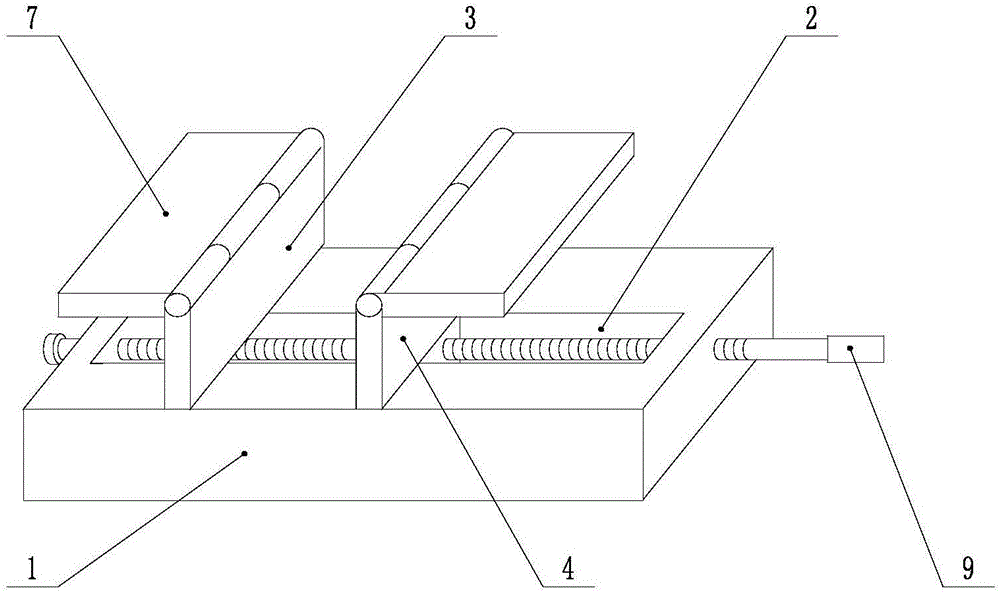

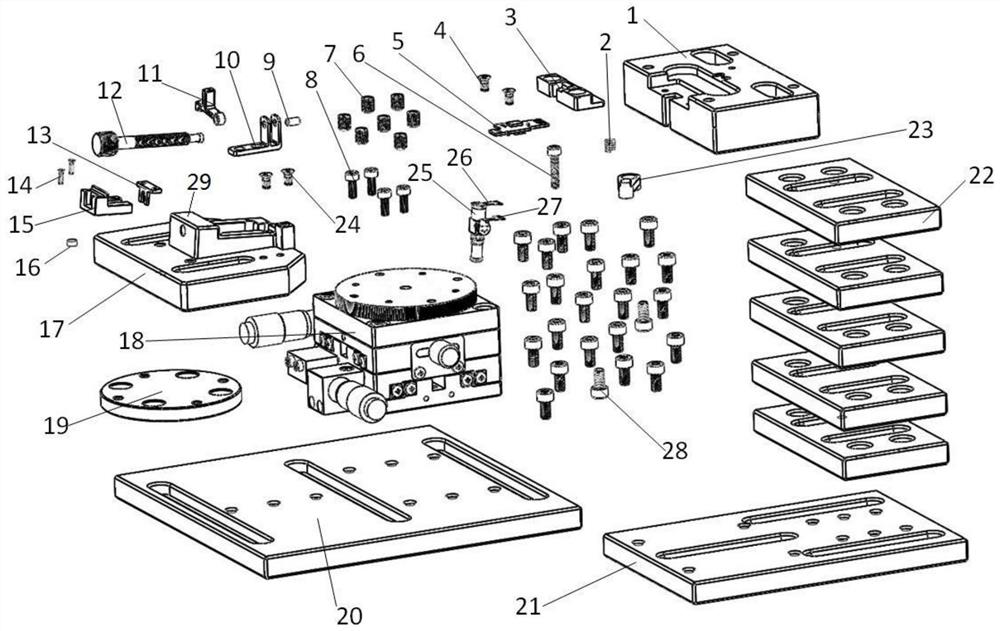

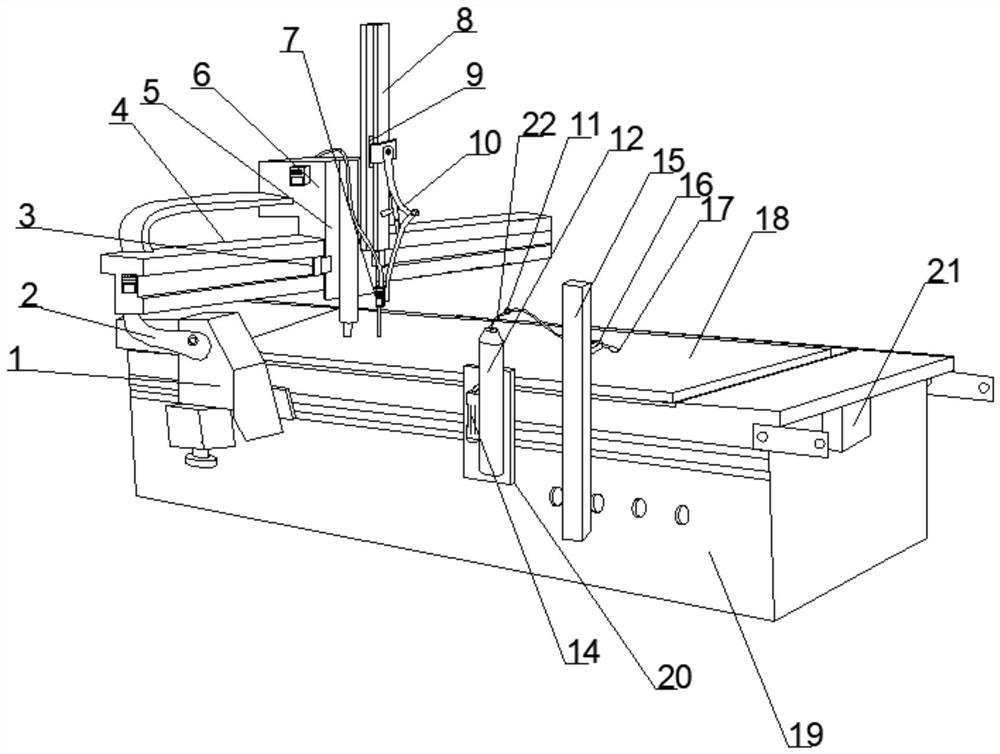

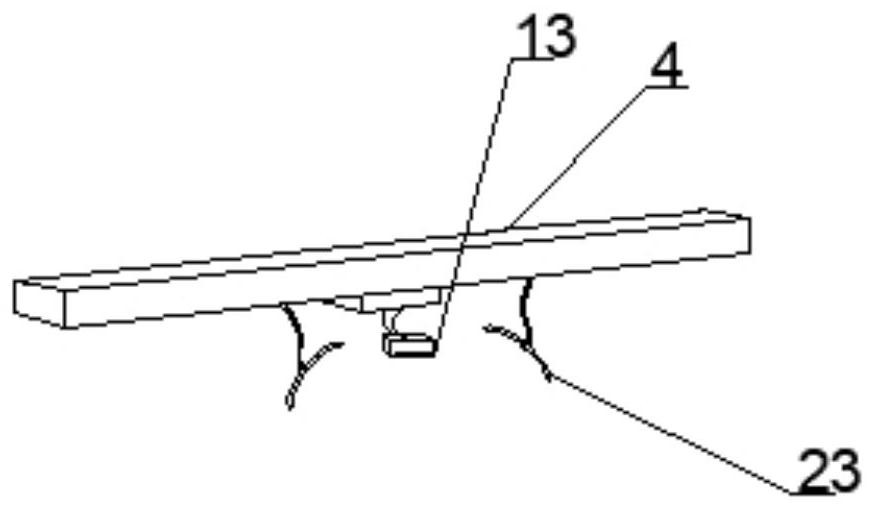

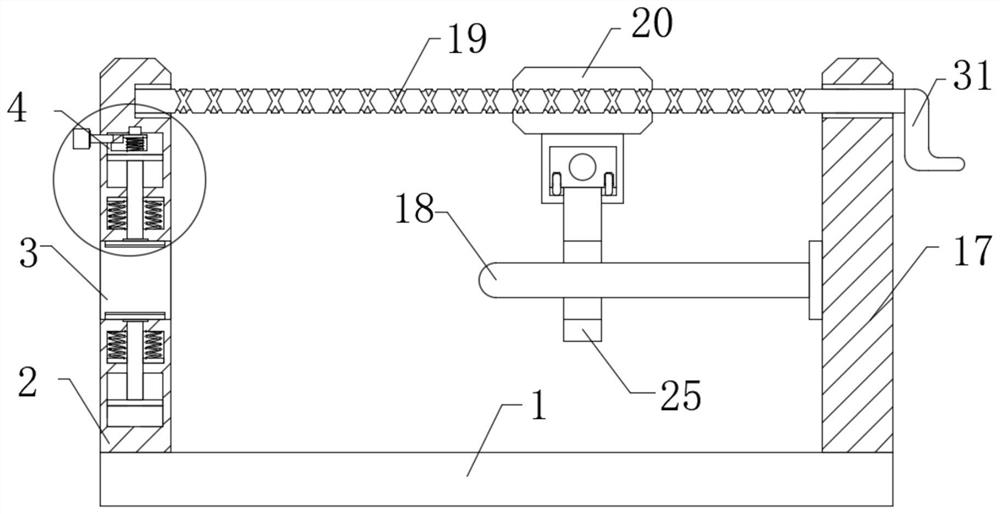

Clamp for friction stir welding

PendingCN110193659APrecise positioningStrong pressing forceWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingBraced frame

The invention provides a clamp for friction stir welding. The clamp is used for clamping a frame and aluminum plates to be welded, wherein the frame comprises a plurality of cross beams which are arranged in parallel and are arranged at intervals and longitudinal beams connecting the end parts of the plurality of cross beams in sequence; the clamp used for friction stirring welding comprises a base, a positioning structure, a pressing mechanism, a turnover driving mechanism, wherein a supporting frame is arranged on the base and is used for supporting the frames and the aluminum plates; the positioning structure is arranged between the base and the frames so as to locate the frames; the pressing mechanism is rotationally connected to the base to press the frames and the aluminum plates; and the turnover driving mechanism is fixed on the base and is used for driving the pressing mechanism to turn over. The frames are accurately positioned, it is guaranteed that the frames and the aluminum plates are completely positioned, and the influence of welding quality caused by positioning problems is avoided; and meanwhile, the manual operation is reduced, the welding efficiency is improved,the pressing mechanism can provide enough press force, so that gaps between the frames and the aluminum plates are prevented from changing during a welding process, and the welding quality is furtherimproved.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD

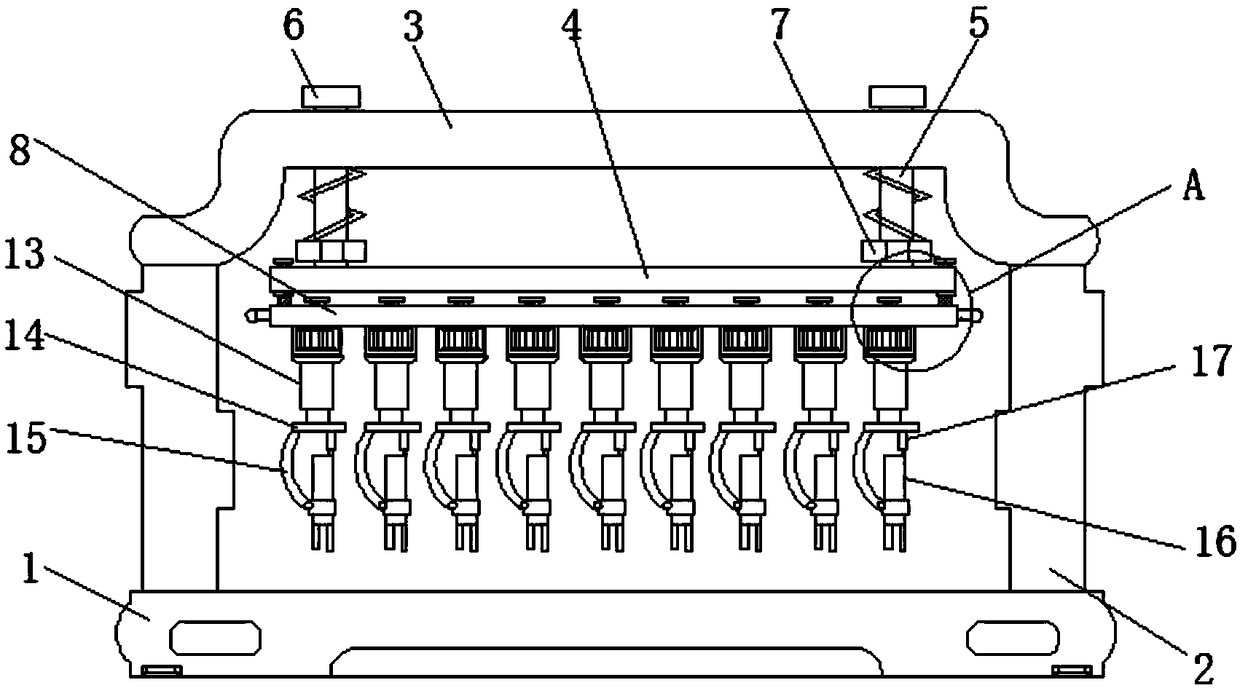

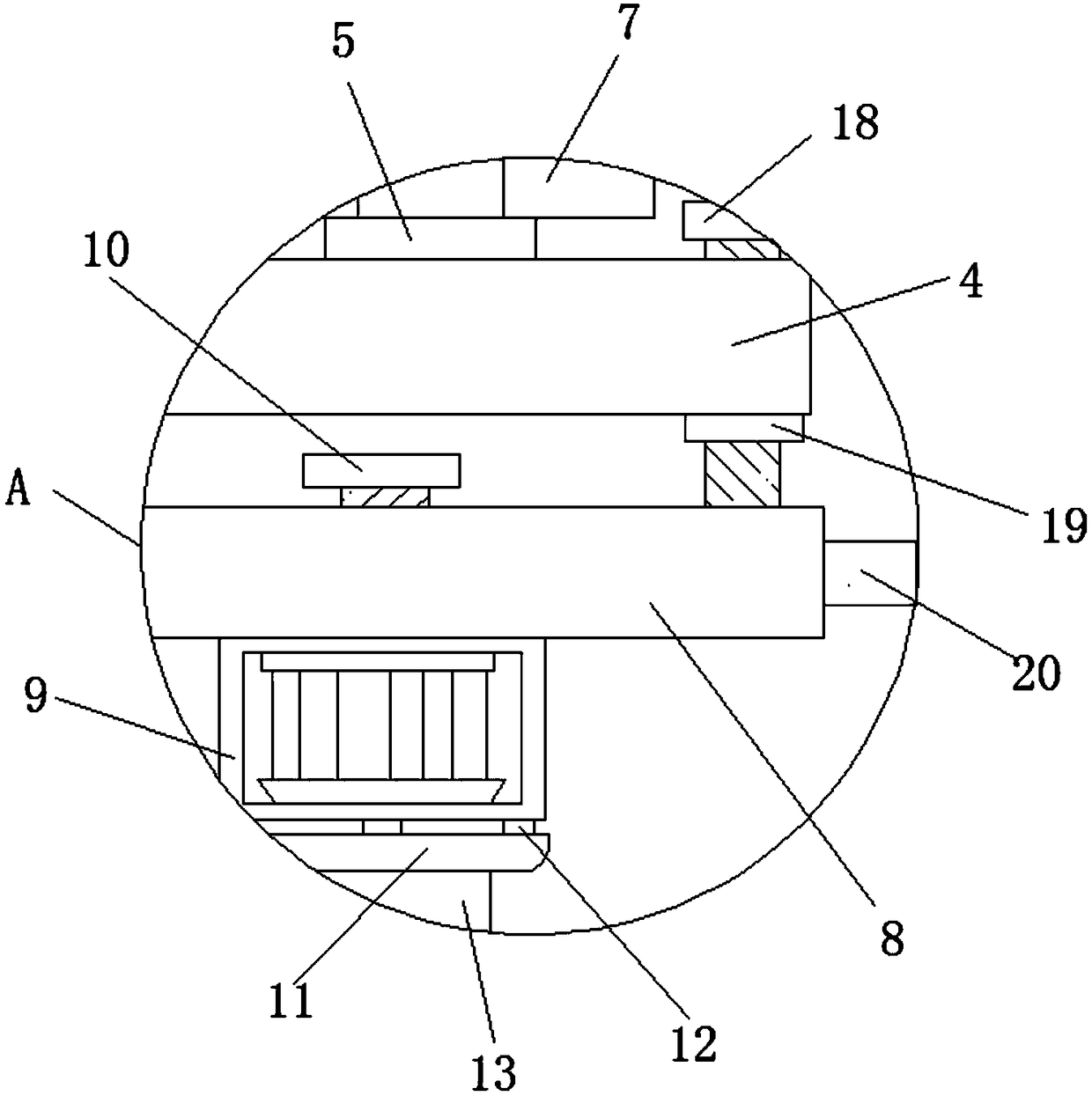

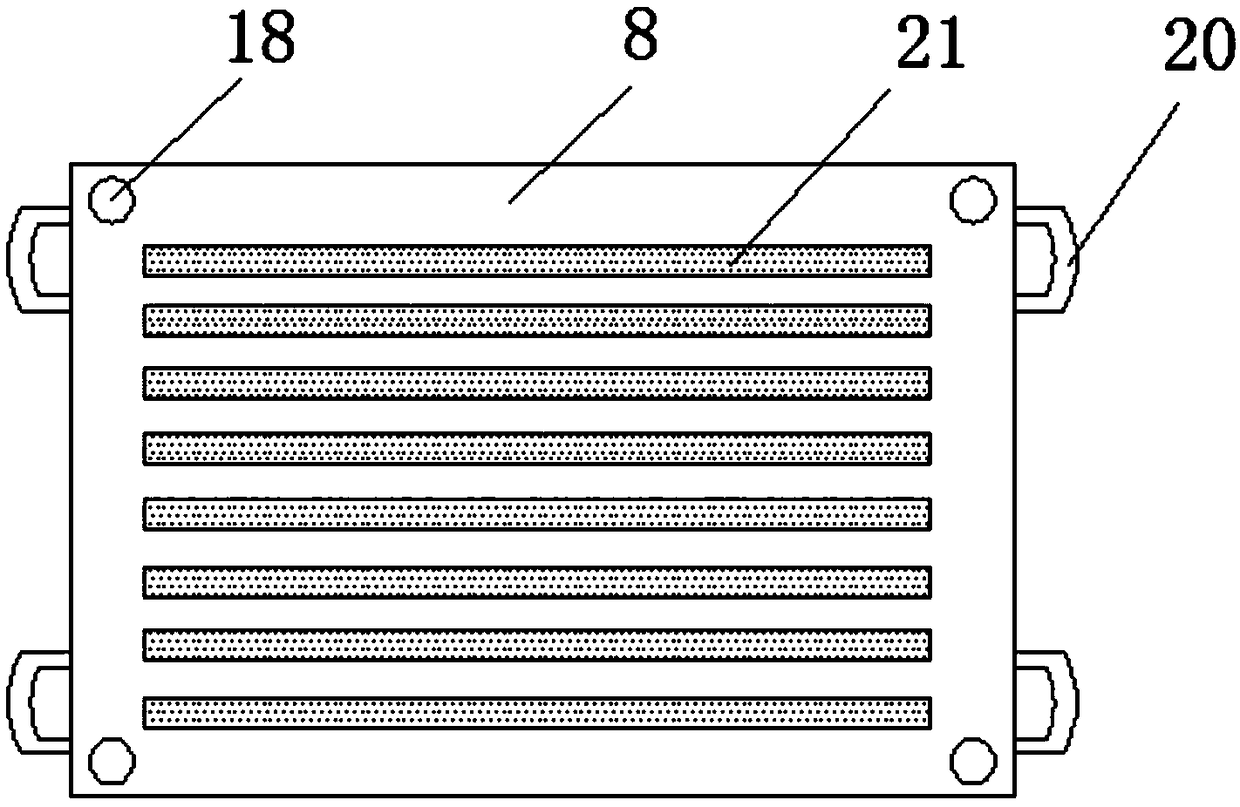

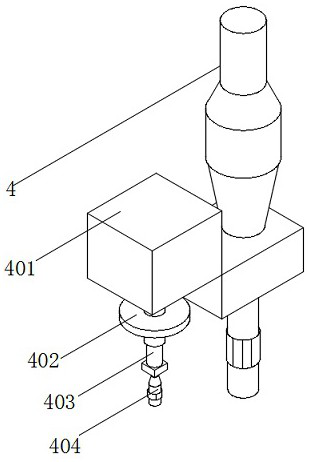

Multi-station automotive part ultrasonic welding facility

PendingCN109175665AEasy CalibrationAvoid affecting welding qualityNon-electric welding apparatusUltrasonic weldingEngineering

The invention provides a multi-station automotive part ultrasonic welding facility, and relates to the field of machinery. The multi-station automotive part ultrasonic welding facility comprises a base. Supporting rods are welded on the top of the base, and a frame plate is connected to the tops of the supporting rods. Welding heads are arranged below the frame plate, and a buffering plate is arranged below the frame plate. Top threaded rods are installed at the four corners of the top of the buffering plate, and buffering springs sleeve the outer walls of the top threaded rods and located below the frame plate. By the adoption of the multi-station automotive part ultrasonic welding facility, due to the arranged buffering springs, the welding heads can slightly move up and down, and the phenomenon that due to the fact that welding heads excessively get close to parts, make hard contact with the parts and cause damage to the parts, the welding quality is affected is avoided. Longitudinal threaded rods slide inside longitudinal through grooves so that the whole welding heads at the bottom can be driven to move forwards and backwards. Transverse threaded rods move inside transverse through grooves so that the individual welding heads can be controlled to move leftwards and rightwards. The welding portion is conveniently calibrated, and the welding quality is improved.

Owner:镇江仕德汽车零部件有限公司

Steel-aluminum joint welding device

InactiveCN110253165AEasy to weldFor lateral movementWelding/cutting auxillary devicesAuxillary welding devicesAlloyEngineering

The invention discloses a steel-aluminum joint welding device. The steel-aluminum joint welding device comprises a protective base, a heating base, conveying rollers, mounting grooves and a shell. The shell is internally provided with the mounting grooves. A feed port is arranged on one side of the sell at the mounting grooves. According to the steel-aluminum joint welding device, a thin copper plate is arranged between a steel plate and an aluminum alloy plate; the aluminum alloy plate and the steel plate make contact with a material guide tube through the thin copper plate; on the one hand, the steel plate and the thin copper plate are isolated through limiting of the thin copper plate, and the situation that the steel plate and the aluminum alloy plate make contact with each other and have a reaction in the heating process and the welding quality is affected by brittle compounds generated from the reaction is avoided; and on the other hand, the thin copper plate achieves the heat conduction effect and conducts heat generated from a heating barrel to the welding ends of the aluminum alloy plate and the steel plate through a delivery tube, a material guide tube and the thin copper plate in sequence to achieve the preheating effect on the steel plate and the aluminum alloy plate. The influence of bubbles generated from uneven heating in the welding process on the welding quality is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

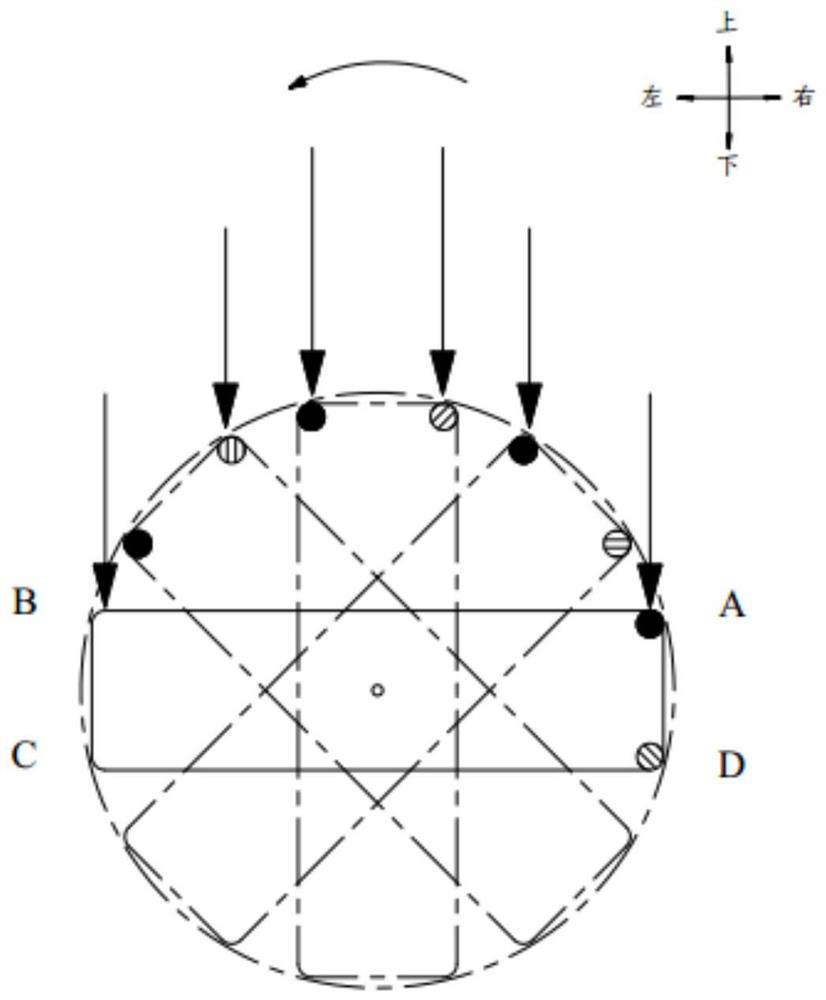

Laser welding method for polyhedral structure

InactiveCN112828463AImprove welding efficiencyNo sudden change in weld temperatureLaser beam welding apparatusContinuous lightRotational axis

The invention discloses a laser welding method for a polyhedral structure. A joint of any two connected to-be-welded connecting surfaces of the polyhedral structure forms a to-be-welded gap, a plurality of sections of to-be-welded gaps are connected to form a welding seam track, and a connecting area of the two connected sections of to-be-welded gaps is a transition welding area. The laser welding method comprises the steps that when welding is conducted to a starting point of the transition welding area, the polyhedral structure rotates around the rotation axis, meanwhile, a welding head correspondingly moves along with rotation of the polyhedral structure, and follow-up is that the welding head moves along with the movement track of the transition welding area; when the welding head moves to the end point of the transition welding area, the to-be-welded gaps to be welded are just located at the horizontal position or the vertical position, and the polyhedral structure stops rotating; and in the moving process of the welding head, laser of the welding head is continuously output. By the adoption of the laser welding method of the polyhedral structure, continuous light emitting welding can be achieved, so that the welding efficiency is improved, and the quality of welding seams is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

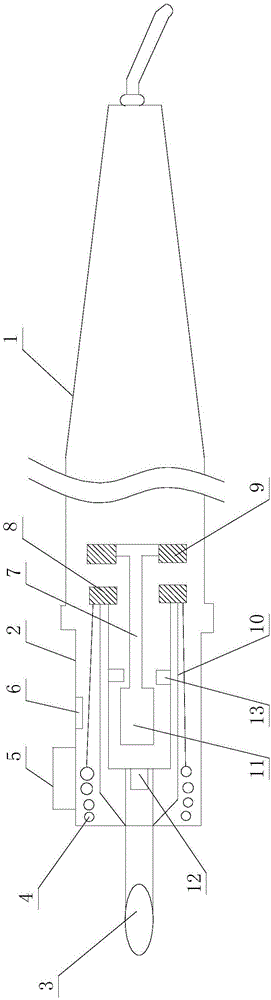

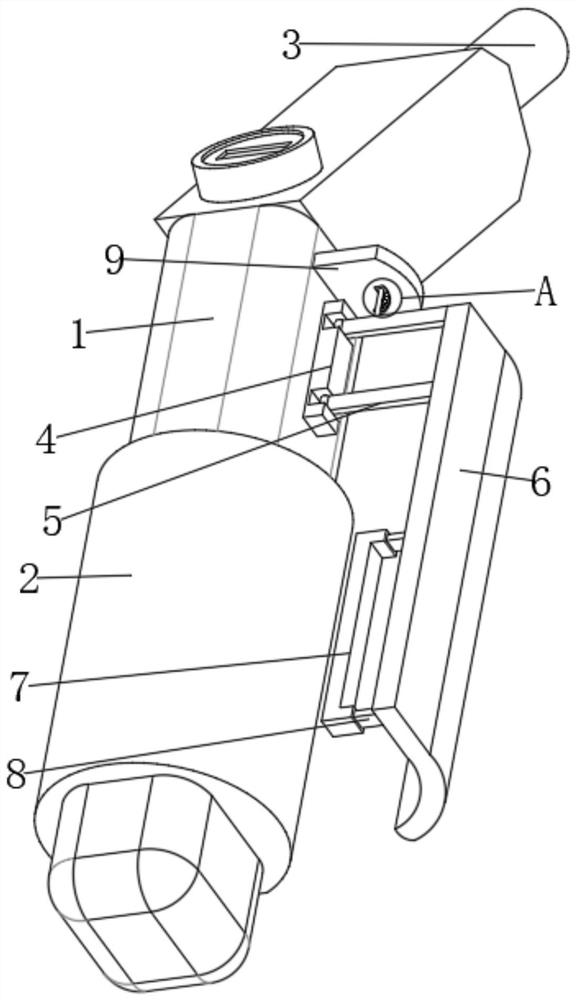

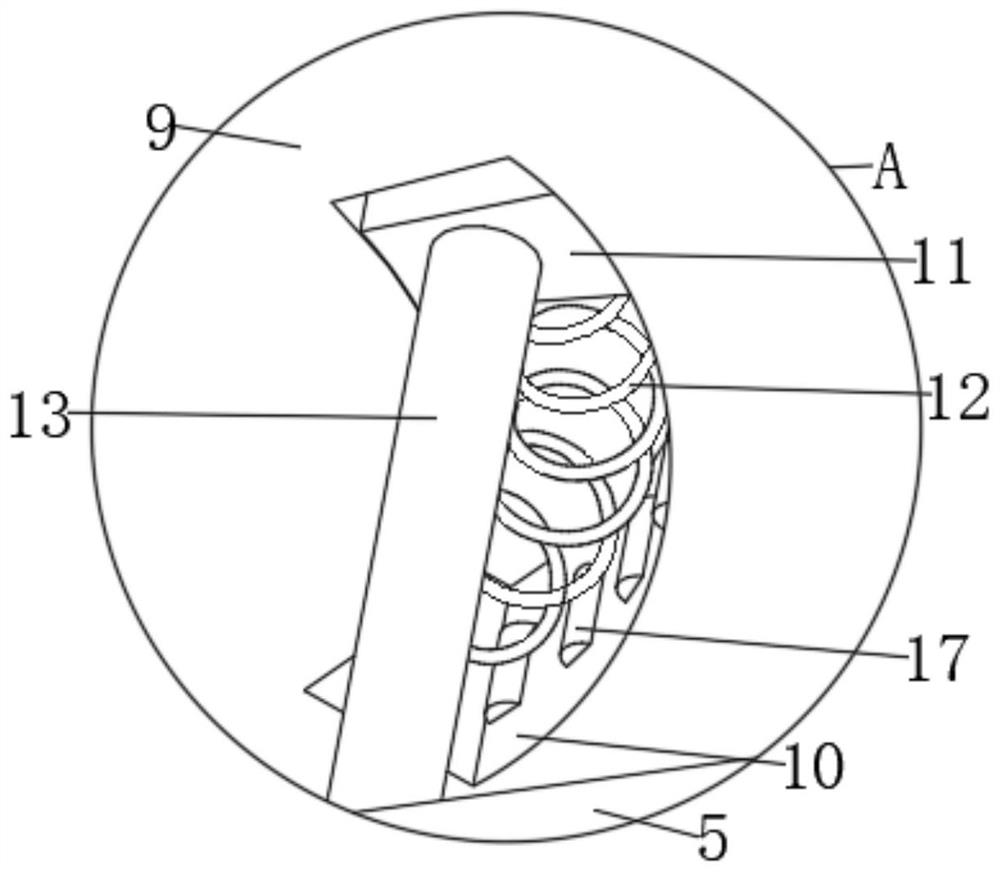

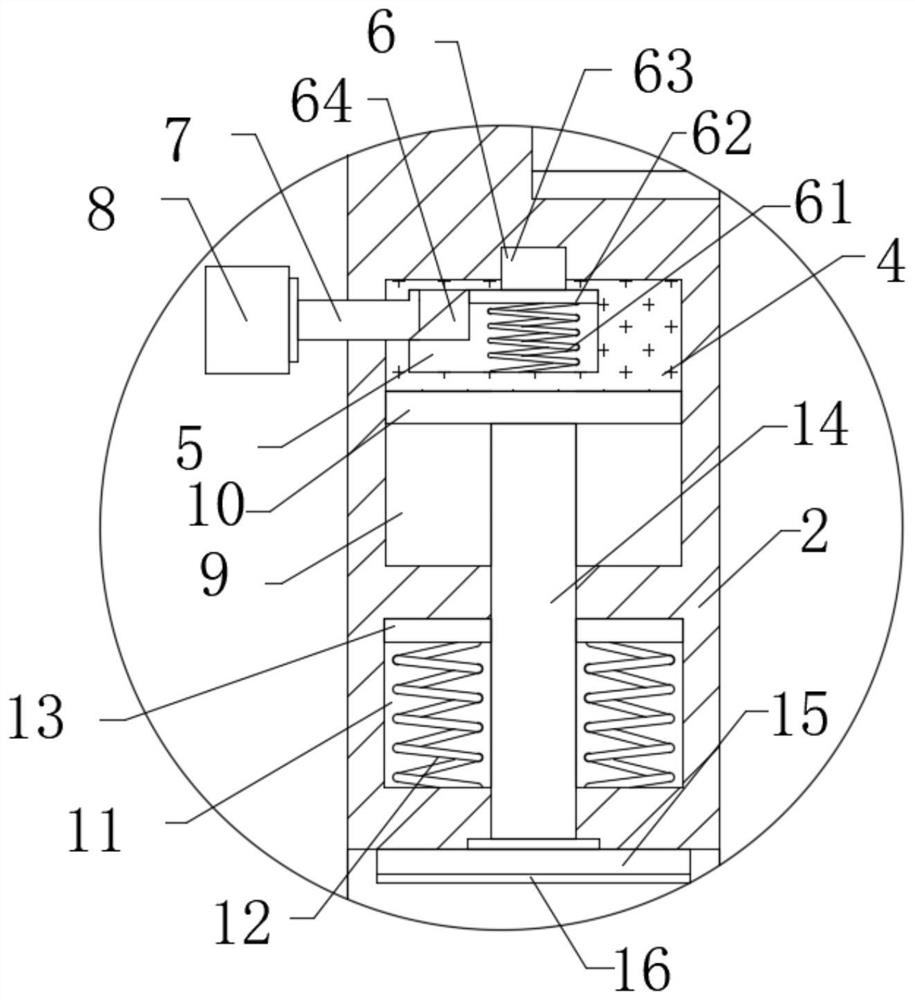

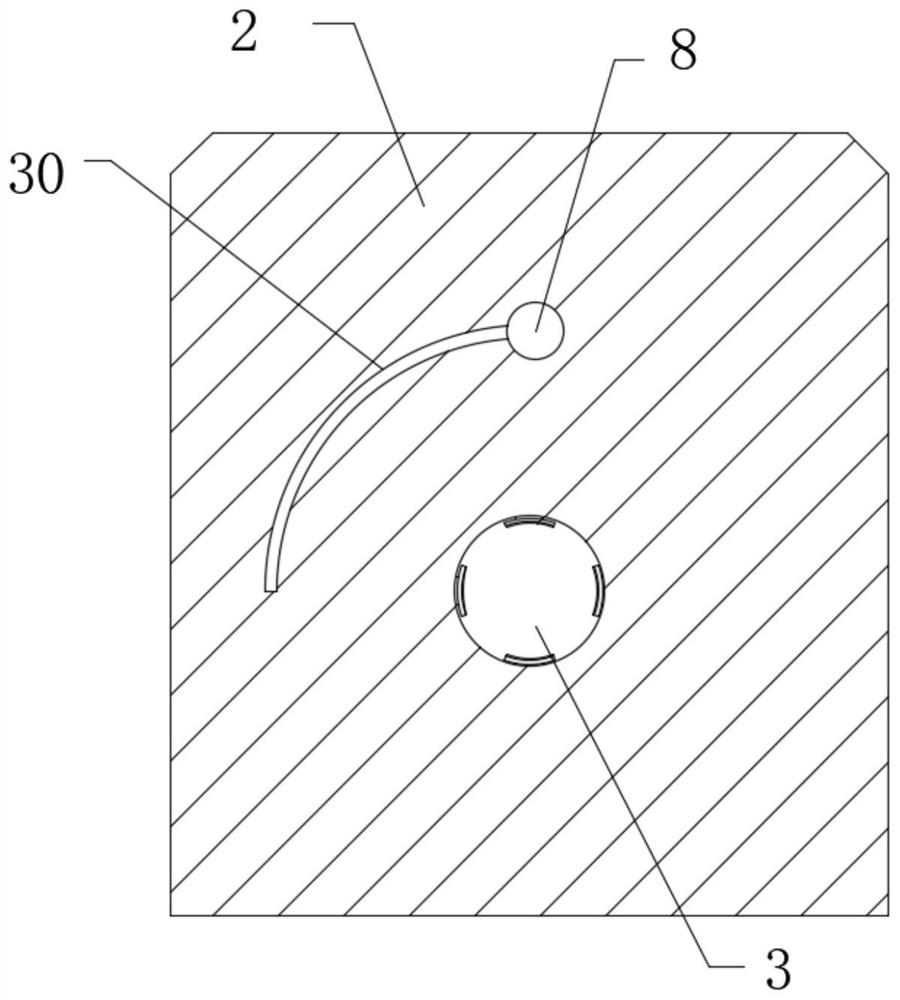

Device for automatically removing multi-diameter stud welding ceramic ring and removing method thereof

ActiveCN105965139AAutomate cleanupAvoid affecting welding qualityWelding accessoriesStud weldingEngineering

The invention discloses a device for automatically removing a multi-diameter stud welding ceramic ring and a removing method thereof. The device is characterized in that an upper outer shell, a middle outer shell, a lower outer shell and an air suction barrel are fixedly connected sequentially from top to bottom; a fixed iron core is positioned above a movable iron core; the fixed iron core and the movable iron core are arranged inside the upper outer shell; an electromagnetic coil is arranged between the movable iron core and the upper outer shell; the bottom of the movable iron core is fixedly connected with a connecting rod through a connecting piece; one end of the connecting rod is positioned in the middle outer shell, and the other end of the connecting rod stretches into the lower outer shell; the middle outer shell is connected on a robot arm through a robot connecting plate; an upper spring sleeve is arranged at the bottom of the inner wall of the upper outer shell; a lower spring sleeve is arranged at the top of the connecting rod; a spring is arranged between the upper spring sleeve and the lower spring sleeve; a linear bearing is arranged in the lower outer shell and sleeves the connecting rod; a plurality of ceramic ring destroy rods are uniformly distributed at the bottom of the connecting rod; the bottoms of the plurality of ceramic ring destroy rods stretch into the air suction barrel; a plurality of connecting rod mechanisms are uniformly distributed on the inner wall of the air suction barrel; and a bottom barrel is located at the bottom of the air suction barrel through the connecting rod mechanisms. According to the device, the cleaning problem of the stud welding ceramic ring can be effectively solved.

Owner:NANJING UNIV OF SCI & TECH

Constant-temperature electric soldering iron for repairing mobile phone

The invention relates to a constant-temperature electric soldering iron for repairing a mobile phone. The constant-temperature electric soldering iron for repairing the mobile phone comprises a handheld part; the front end of the handheld part is connected with a heating part, and the tail end of the handheld part is connected to a power line; the front end of the heating part is provided with a soldering bit, a permanent magnet is arranged in the center of the inner cavity of the heating part and is connected with a contact spring plate through a small shaft, the outside of the permanent magnet is sleeved by a support frame, the soldering bit is fixedly connected with the support frame, and a soft magnetic metal block is mounted at the soldering bit; and the support frame is provided with a contact corresponding to the contact spring plate, and the contact is connected with a heater through a wire on which a magnetic switch is mounted. The constant-temperature electric soldering iron is simple in structure, the phenomenon that the soldering quality is affected because a soldering iron core is always in a heating state is avoided, the service life of the electric soldering iron is prolonged, and meanwhile, the electric energy is saved.

Owner:刘惠强

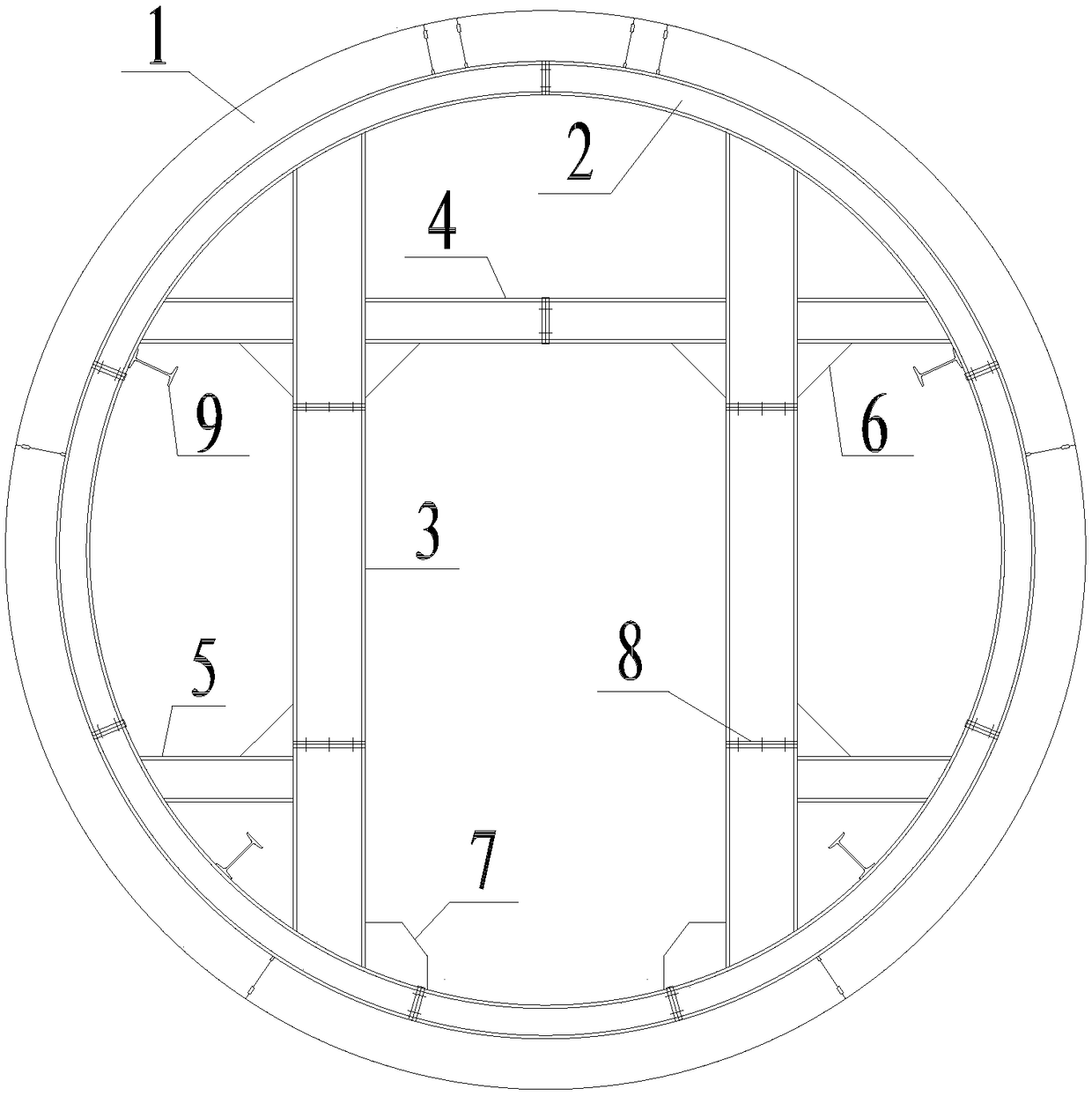

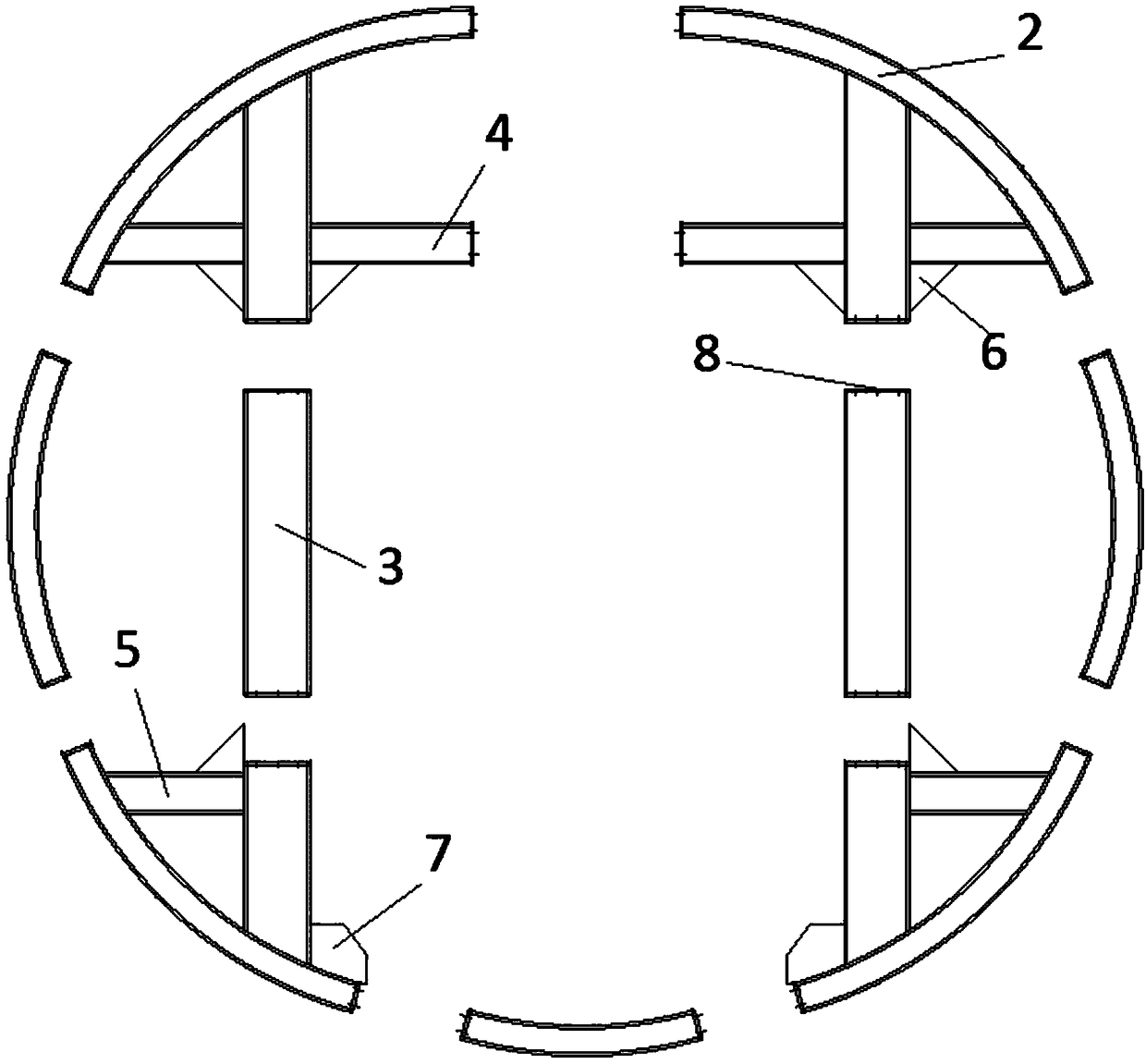

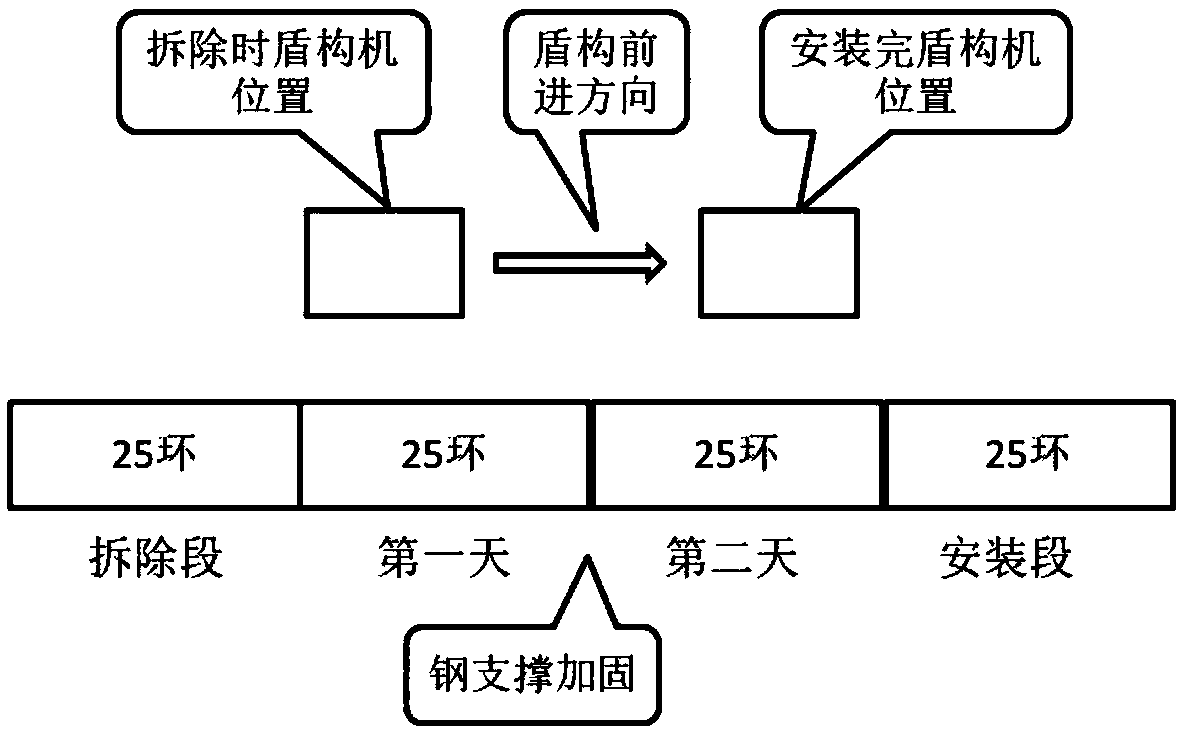

Stacking shield modular steel support reinforcement structure capable of being installed and disassembled quickly

PendingCN109441490AReliable support reinforcement measuresEnsure construction safetyUnderground chambersTunnel liningComputer moduleModular design

The invention discloses a stacking shield modular steel support reinforcement structure capable of being installed and disassembled quickly. An annular I-shaped steel main support is arranged on the inner side of a the lower shield tunnel segment; the annular I-shaped steel main support is in an annular shape, and is composed of a plurality of arc-shaped annular I-shaped steel supports; two top end modules are connected with each other through the annular I-shaped steel supports and a first horizontal steel support which are corresponding to the two top end modules; two bottom end modules areconnected by the other annular I-shaped steel support; the two top end modules and the two bottom end modules are in one-to-one correspondence; and the corresponding top end module and the bottom endmodule are connected by another annular I-shaped steel support and vertical steel supports. The stacking shield modular steel support reinforced structure capable of being installed and disassembled quickly can provide reliable support and reinforcement measures for the lower shield, through the modular design of a steel support reinforcement system, the on-site operation procedures are simplified, and the beneficial effects of rapid installation and disassembly of the steel supports are realized.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

Error compensation type laser welding equipment with crack detection function

InactiveCN114473205AGuarantee welding qualityRealize the effect of crack compensationLaser beam welding apparatusEngineeringLaser soldering

The error compensation type laser welding equipment with the crack detection function comprises an operation table body, a vertical frame is installed at the top of the operation table body, and a welding gun body is installed at the bottom of the tail end of a telescopic transverse rod; the surface of the welding gun body is sleeved with a connecting block, an electric telescopic rod is installed at the bottom of the connecting block, the surface of the electric telescopic rod is sleeved with a sleeve disc, a crack detector is installed at the bottom of the sleeve disc, a welding head is installed at the bottom of the electric telescopic rod, and the electric telescopic rod is electrically connected with the crack detector. A first sliding groove is formed in the top of the operation table body, a storage cabinet is installed on one side of the bottom of the operation table body, and a tail gas purification box is installed on the surface of one side of the storage cabinet. By arranging the welding gun body, the welding head, the electric telescopic rod and the crack detector, crack compensation welding treatment can be conducted while the welding equipment is assisted to achieve link crack detection, and the welding quality is guaranteed.

Owner:江苏洛柳精密科技有限公司

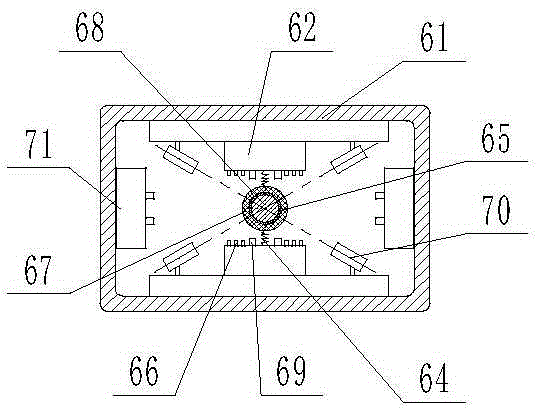

Multi-direction welding head for laser welding robot

ActiveCN105364304AAdjust the magnetic forceAvoid shakingLaser beam welding apparatusLaser NozzleEngineering

The invention belongs to the field of welding robots, and specifically discloses a multi-direction welding head for a laser welding robot. The multi-direction welding head comprises a laser nozzle and a rectangular swinging drum; the laser nozzle is located within the rectangular swinging drum; mounting bases are arranged on two opposite sides of an inner wall of the rectangular swinging drum; a first main electromagnet and two auxiliary electromagnets are arranged on each mounting base, and the two auxiliary electromagnets are symmetrical relative to the first main electromagnet; second main electromagnets are mounted on the other two side surfaces of the inner wall of the rectangular swinging drum; an annular magnet is mounted on a tail of the laser nozzle and located within a magnetic field cavity formed by the first main electromagnets and the second main electromagnets; an elastic piece is arranged on each first main electromagnet; anti-collision columns are arranged on the first main electromagnets and the second main electromagnets. A welding robot provided with the multi-direction welding head for the laser welding robot is relatively low in energy consumption relative to a welding robot provided with a traditional welding head when crisscross tiny straight joints are welded.

Owner:CHONGQING LEIBAO LASER INTELLIGENT ROBOT MFG

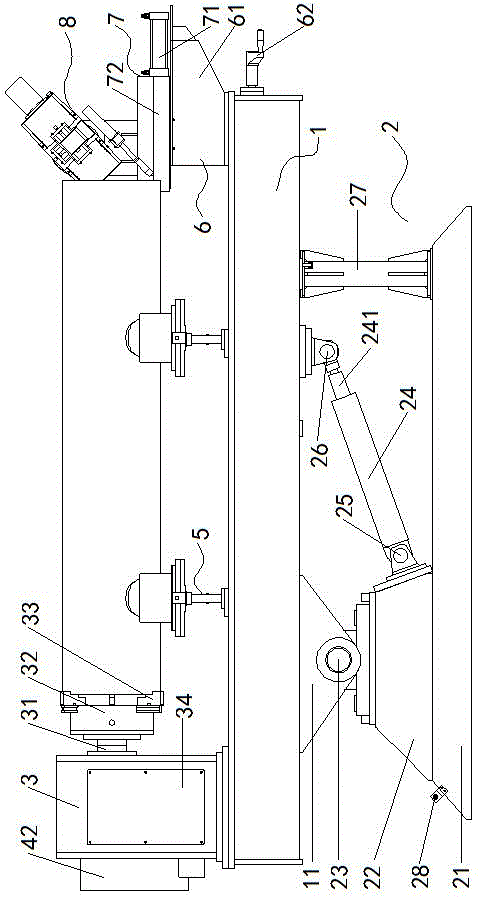

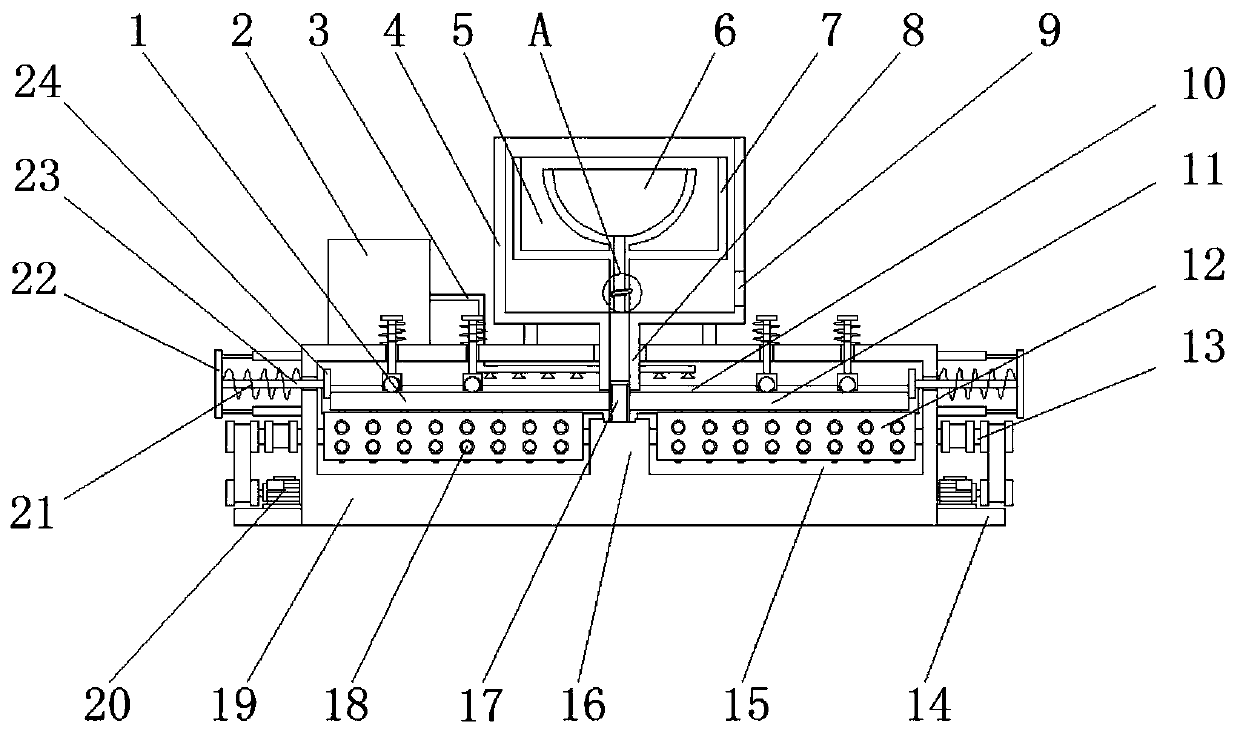

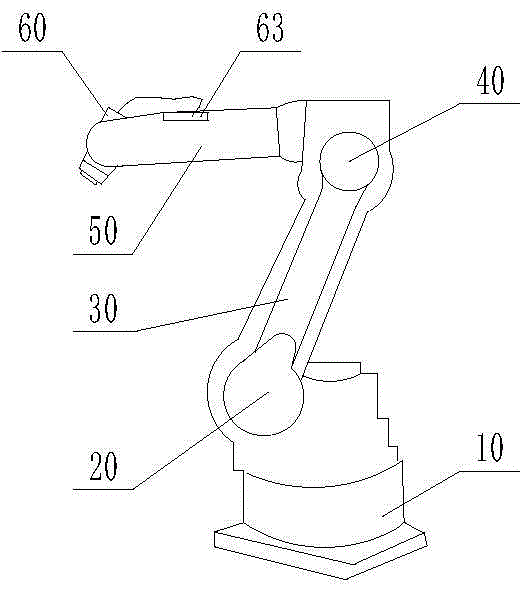

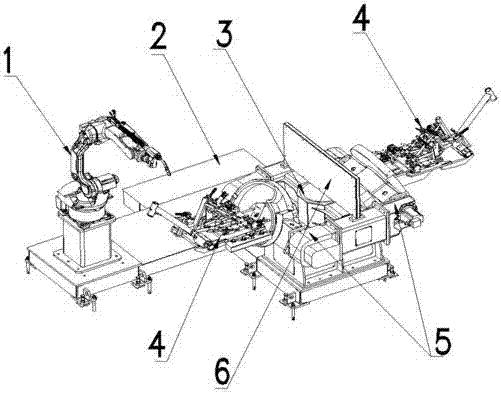

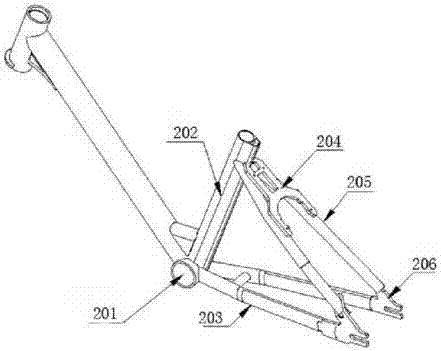

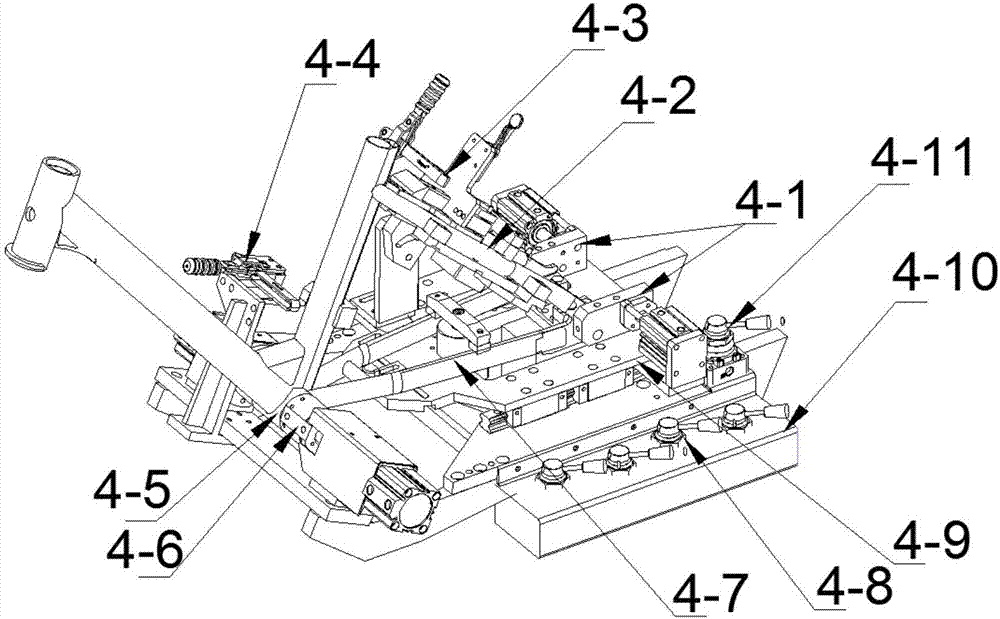

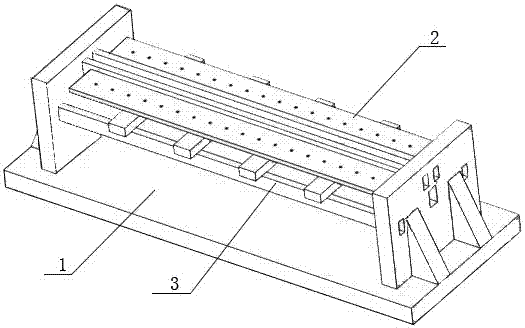

Bicycle rear tripod robot welding system

InactiveCN107081544AReduce travel timeReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesRobot controlRobot welding

The invention discloses a robot welding system for a bicycle rear tripod, which includes a base, on which a station switching positioner is arranged, and two-axis positioners are respectively connected to the two sides of the station switching positioner, and the whole welding The system achieves 11-axis displacement linkage. The two-axis positioner is connected with a rear tripod welding fixture, and a welding robot is installed on one side of the rear tripod welding fixture on the base, and a welding robot is installed on one side of the base. The robot control cabinet that controls the welding robot, the station switching rotary positioner and the two-axis positioner. The present invention adopts a double-station design, relies on the rotary positioner to switch the positions of the dual-axis positioner, realizes the switching of the positions, and reduces the clamping of the rear tripod welding fixture on the rear tripod by the operator on the two positions. The time to go back and forth from time to time reduces the labor intensity of workers.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

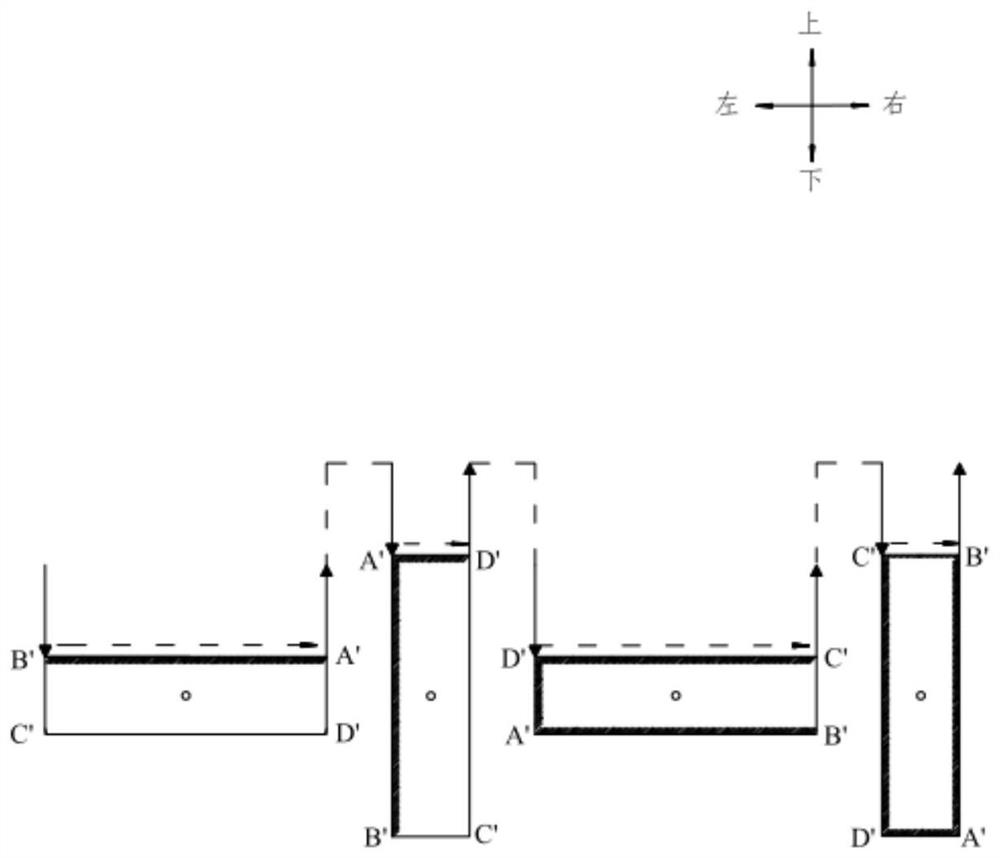

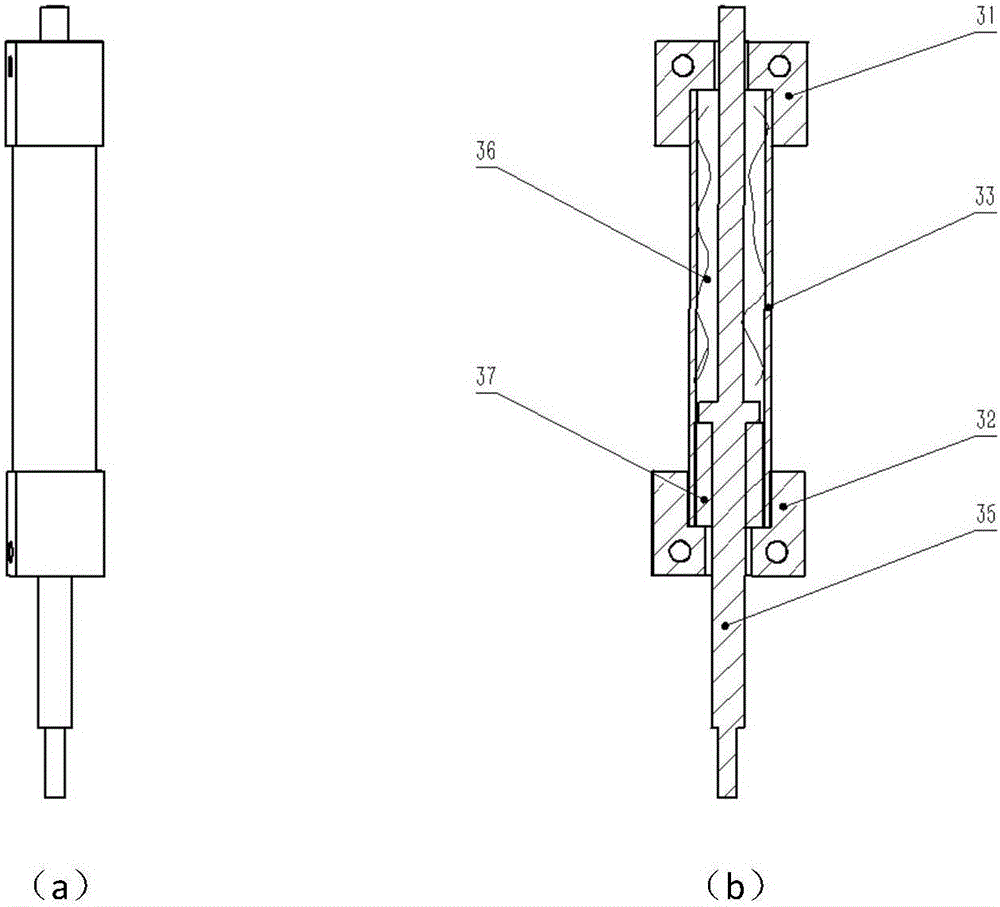

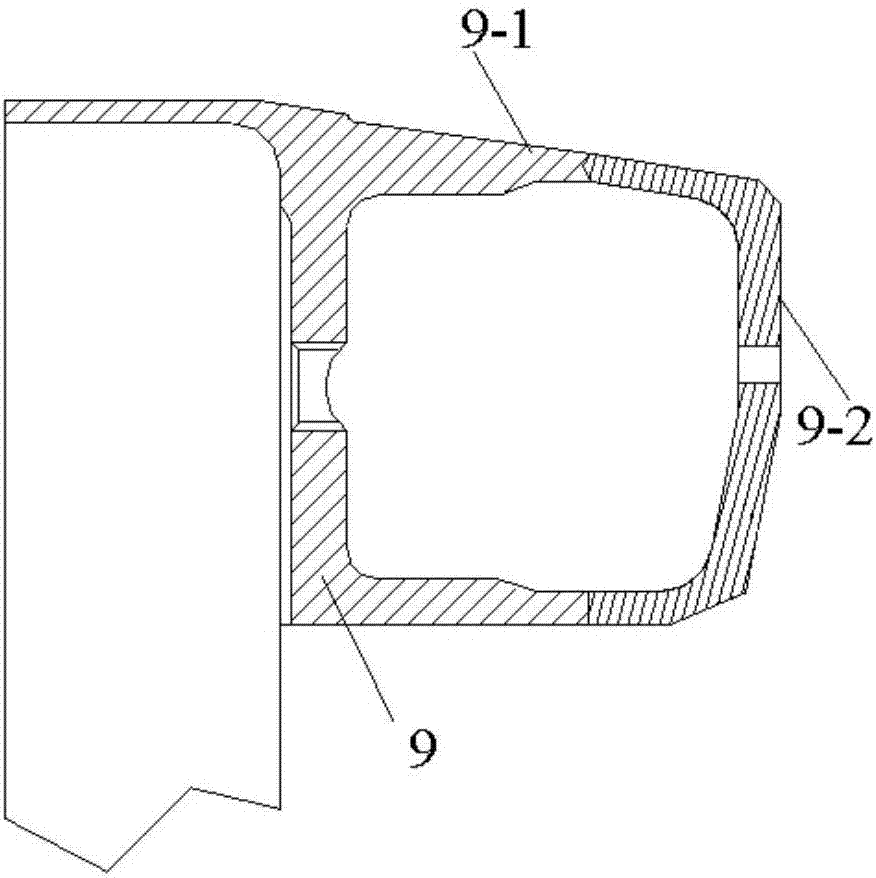

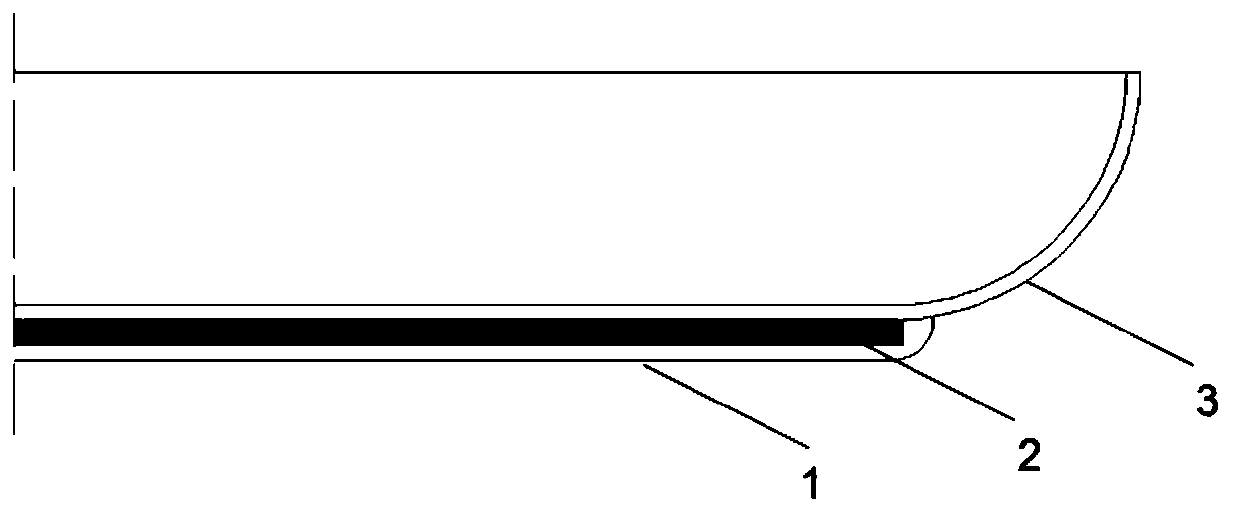

Thin-wall barrel high-energy beam precise welding tool and welding method

ActiveCN107442920AImproved stability and arc precisionPrevent cylinder deformationElectron beam welding apparatusPneumatic pressureDimensional precision

Disclosed are a thin-wall barrel high-energy beam precise welding tool and welding method. The thin-wall barrel high-energy beam precise welding tool comprises a fixed support base, a front-side arc-shaped tool compressing device, a front-side arc-shaped fixing tool and a reverse-side arc-shaped fixing tool. A to-be-welded thin-wall barrel placed on the thin-wall barrel high-energy beam precise welding tool can be fixed stably through the front-side arc-shaped fixing tool and the reverse-side arc-shaped fixing tool. The front-side arc-shaped tool compressing device compresses on the front-side arc-shaped fixing tool. A high-energy beam welds a to-be-welded weld joint after passing a weld joint A and a weld joint B. After welding, a screw or a pneumatic pressure device is loosened, the front-side arc-shaped fixing tool is taken out, and the welded barrel is taken out. Compared with the prior plane fixing mode, the thin-wall barrel high-energy beam precise welding tool and welding method improve the stability of barrel fixing and precision of radian, barrel deformation during fixing is avoided, the good shape dimensional precision of the thin-wall barrel is ensured, operation is convenient, so that operation time is saved, and welding work efficiency is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Titanium-alloy supporting ring fusion-welding gas shield trailing cover and shielding method

The invention discloses a titanium-alloy supporting ring fusion-welding gas shield trailing cover and a shielding method. A trailing cover main body of a shield trailing cover is of a box structure and provided with an opening in the front face and an opening in the bottom face; a welding gun nozzle mounting hole is formed in the front end of the top face of the trailing cover main body, and an upper pipe with argon is arranged on the top face of the trailing cover main body; an inclined side plate is connected to the lower end of the left side face of the trailing cover main body and is inclined toward the outer side of the trailing cover main body; a web is connected to the right side face of the trailing cover main body, and a side pipe with argon is connected to the side face of the web; and the lower end of the inclined side plate and the lower end of the right side face of the inclined side plate are each of a circular arc structure which has the same curvature with the welding face of an outer circle of a supporting ring. The titanium-alloy supporting ring fusion-welding gas shield trailing cover can ensure that the heat affected area with the temperature of welding seam molten pool and parts exceeding 400 DEG C is not oxidized.

Owner:AECC AVIATION POWER CO LTD

Portable auxiliary supporting frame welding fixture suitable for angle steel tower installation

InactiveCN107175453AAvoid affecting welding qualityIncrease the gapWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower

The invention discloses a portable auxiliary support frame welding fixture suitable for angle steel tower installation, comprising a base, a guide groove is arranged on the base, a fixed support plate is arranged at one end of the guide groove, and a movable support plate is arranged at the end of the guide groove away from the fixed support plate , a moving part is arranged under the moving support plate, a screw rod is arranged through the moving part, the moving part and the screw rod are located in the guide groove, the moving part is screwed with the screw rod, and the fixed support plate and the moving support plate are hinged with a rotating support plate, The angle steel is placed between the fixed support plate and the movable support plate, the screw rod is rotated to compress the fixed support plate and the movable support plate, and the angle of the rotating support plate is adjusted according to the angle of the angle steel. The invention can clamp the angle steel between the fixed support plate and the movable support plate, the angle steel is not easy to generate large vibration, and there is no large gap between the two angle steels, which ensures the welding quality, and can be used according to the angle of the angle steel Adjust the angle of the rotating support plate, and its application range is wider.

Owner:四川宇桥铁塔有限公司

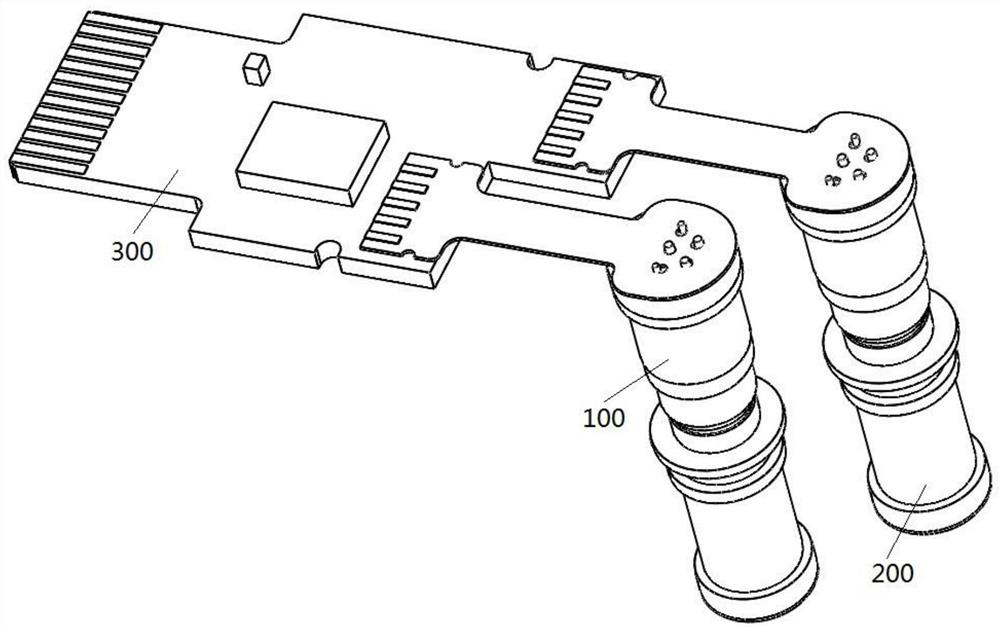

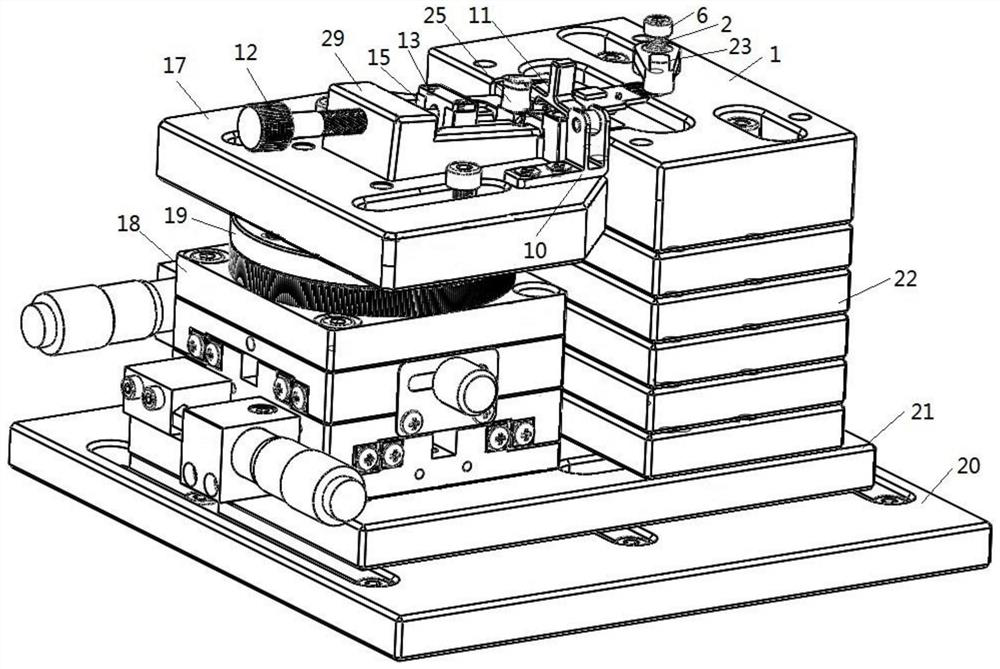

Tool for welding optical device flexible board and PCB

ActiveCN112091344AAvoid affecting welding qualityImprove applicabilitySoldering auxillary devicesPhysicsBackplane

The invention relates to the field of communication modules, in particular to a tool for welding an optical device flexible board and a PCB. The tool comprises a bottom plate, a three-dimensional table, a cushion block, a device end clamping seat and a PCB end clamping seat. Only a small number of parts, such as the PCB end clamping seat, a PCB bonding pad end cushion block, the device end clamping seat, a sliding block and a deformation pressing device, need to be selectively replaced according to an actual product structure so that the tool can be suitable for most BIDI optical devices, canalso be used for positioning welding of single-transmitting and single-receiving optical devices, and is high in compatibility, universality and flexibility. The problems that in the welding process,the optical devices are loosened, a PCB is prone to tilting, and a BIDI optical device flexible board cannot be compatibly welded are effectively solved, and the tool is particularly suitable for welding of the optical device flexible board needing shaping.

Owner:成都新易盛通信技术股份有限公司 +1

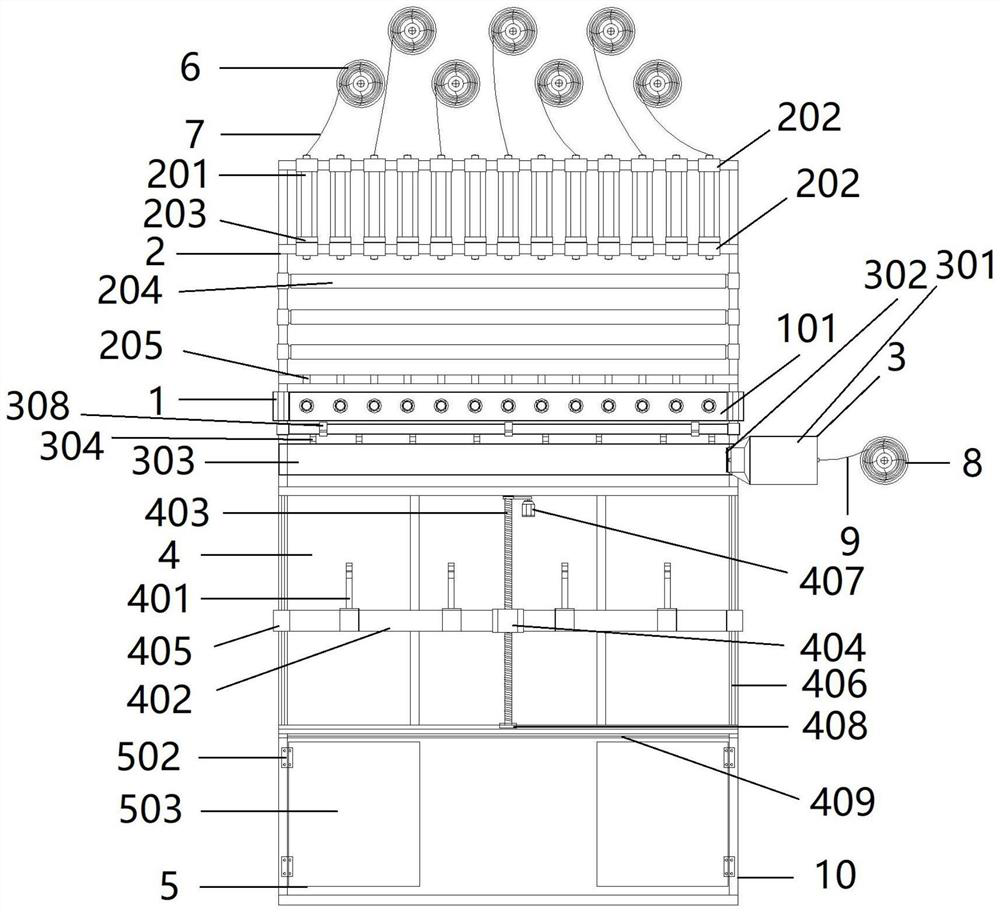

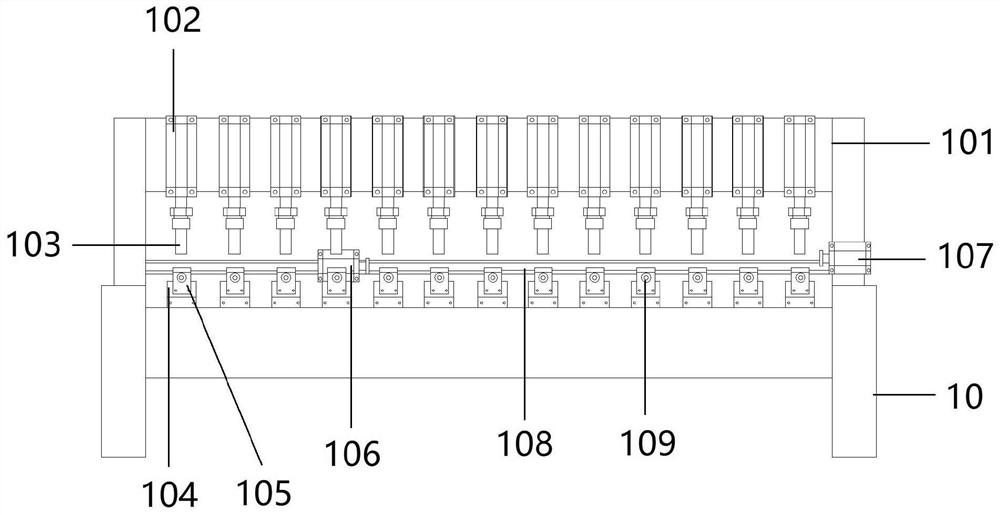

Automatic projection welding machine

The invention discloses an automatic projection welding machine. The automatic projection welding machine comprises a rack, a projection welding device, a warp wire inlet device, a weft wire inlet device, a discharging device and a discharging device, wherein the projection welding device, the warp wire inlet device, the weft wire inlet device, the discharging device and the discharging device areinstalled on the rack; warp steel bars wound around a warp steel bar disc penetrate into a rotary wire inlet pipe installed on the rack; wire inlet rolling shafts are distributed in an up-down staggered manner, and one end of each wire inlet rolling shaft is connected with a rolling shaft servo motor used for driving the corresponding wire inlet rolling shaft to rotate to drive wire inlet of thecorresponding warp steel bar; driven rolling wheels transfer weft steel bars to the warp steel bars between an upper electrode and a lower electrode for welding; an upward hook is arranged at the front end of a mechanical arm and used for hooking a net rack to move; a mechanical arm air cylinder controlling the mechanical arm to rotate up and down is arranged at the lower portion of the mechanicalarm; and a material cutting cutter for cutting off the net rack is arranged at the rear end of a discharging frame and used for cutting the net rack into finished net racks. According to the automatic projection welding machine, automatic feeding, cutting, welding and discharging of the warp steel bars and the weft steel bars are achieved, manpower is saved, the production efficiency is improved,unnecessary hurt to operators is avoided, and the quality of the net rack is better.

Owner:LAIWU IRON & STEEL GRP

Laser welding equipment and using method thereof

InactiveCN113798668AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryWelding process

The invention discloses laser welding equipment, and relates to the technical field of welding. The laser welding equipment comprises a workbench, a first vertical plate, a first supporting plate and a first motor, a first screw rod is fixedly connected to the output end of the first motor, a first moving plate is connected to the outer wall of the first screw rod in a threaded mode, and a laser welding gun is arranged at the bottom of the first moving plate; a second supporting plate is arranged on the surface of the workbench, a first air cylinder is installed on the surface of the second supporting plate, a concave plate is fixedly connected to the output end of the first air cylinder, a first clamping plate and a second clamping plate are fixedly connected to the surface of the concave plate, and a first fixing plate and a second fixing plate are fixedly connected to the surface of the second supporting plate; and the first air cylinder is started to enable the first clamping plate and the second clamping plate to make contact with the other two sides of a workpiece, all faces of the workpiece can be conveniently clamped, the phenomenon that the welding quality is affected due to loosening in the welding process is avoided, the first motor is started to drive the laser welding gun to move, and therefore the workpiece can be conveniently welded.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

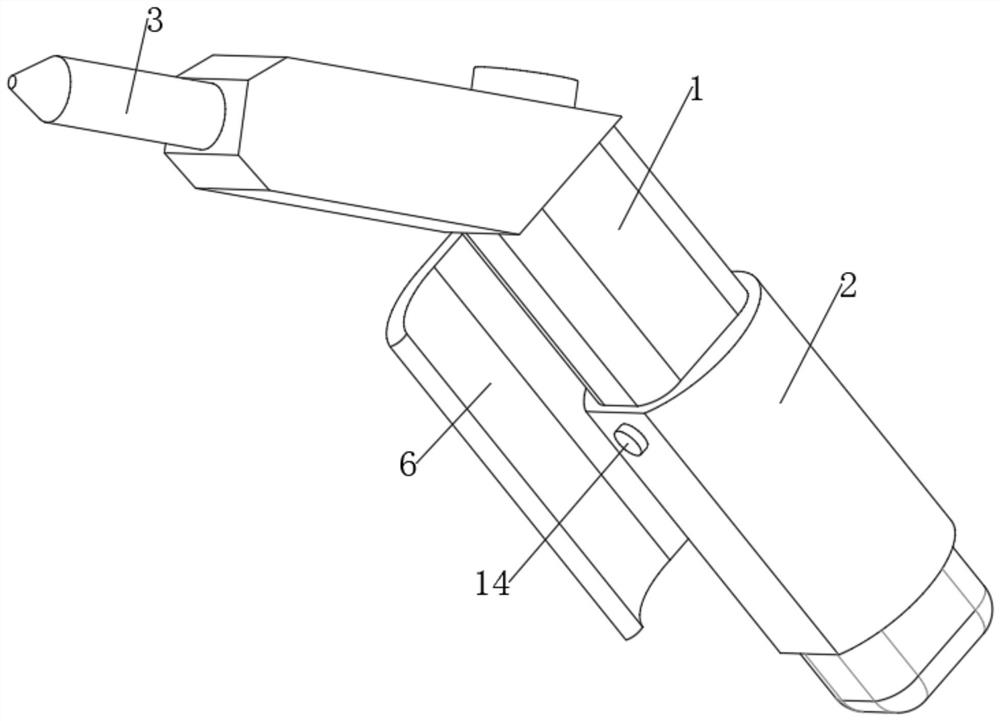

Handheld laser welding equipment

ActiveCN113560715AAngle stableAvoid affecting welding qualityLaser beam welding apparatusHand partsHand held

The invention relates to handheld laser welding equipment. The handheld laser welding equipment comprises a welding gun, wherein a welding head is fixed to the rear end of the welding gun, the welding gun is fixedly sleeved with a handle, and a control switch is fixed to the bottom of the handle in a penetrating mode; a fixing block and a guide plate are fixed to one side of the welding gun through bolts, and a connecting frame is hinged to the other side of the fixing block; a directional plate is fixed to the other side of the connecting frame through bolts, and the section of the directional plate is J-shaped; a guide groove is formed in the front end of the guide plate, and the section of the guide groove is arc-shaped; a guide block is slidably connected into the guide groove, and a guide spring is fixed between the guide block and the inner wall of the guide groove through bolts; and the same connecting rod is fixed between the guide block and the connecting frame through bolts. The bottom of the directional plate makes contact with a working table or a table top, so that the hand can be stably supported through contact stress between the welding head and a welding seam part and contact stress between the directional plate and the working table, and therefore the situation that the hand shakes, and consequently angle deviation is caused is effectively avoided.

Owner:江阴市金祥机械有限公司

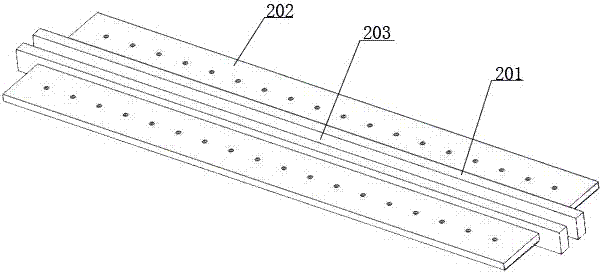

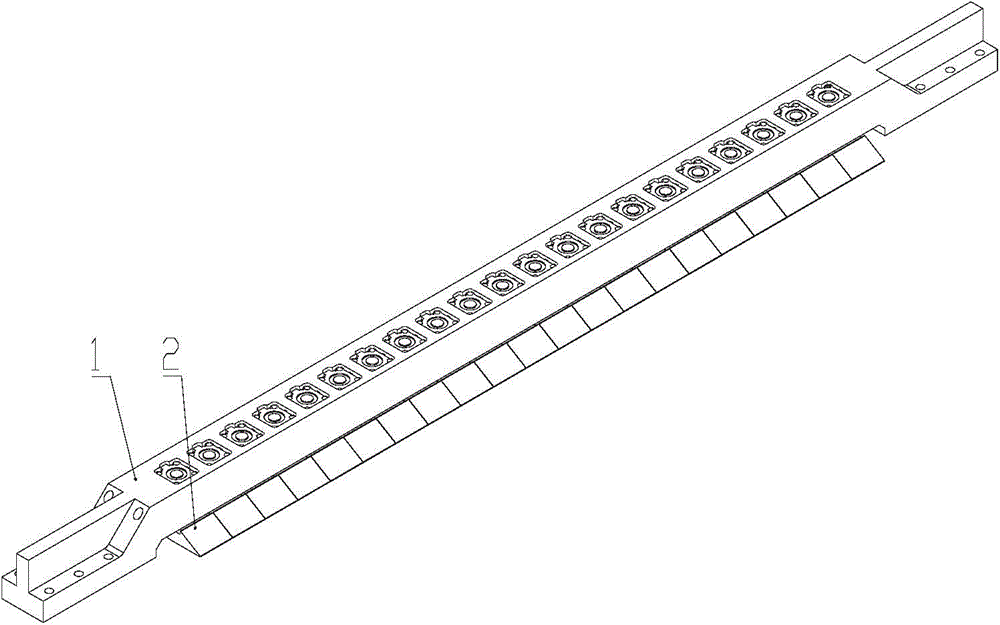

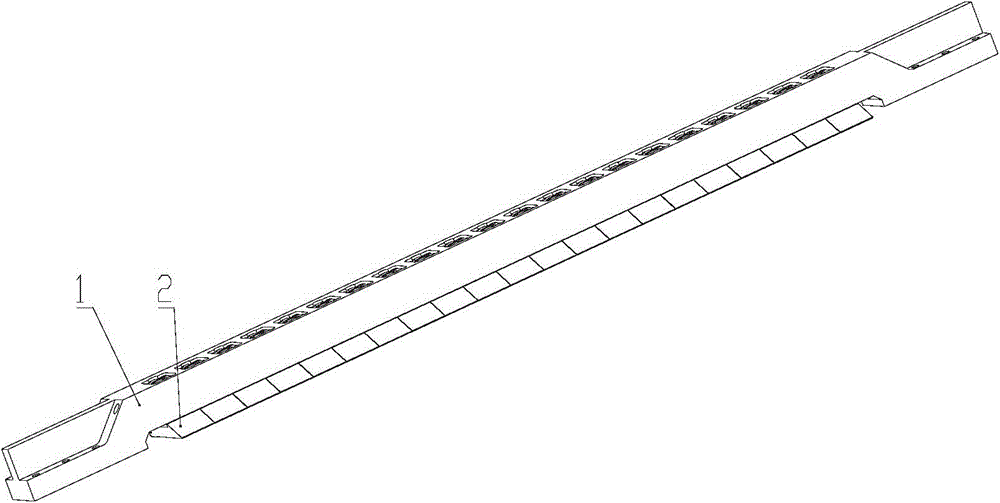

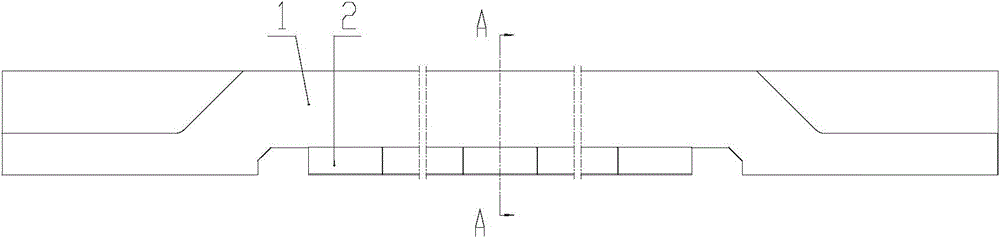

Panel pressing device applied to laser tailor-welding

InactiveCN104416291AImprove the quality of correctionGood compression effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention belongs to the technical field of laser welding, and particularly relates to a panel pressing device applied to laser tailor-welding. The panel pressing device comprises a pressing beam and pressing components, wherein the pressing beam is provided with a plurality of stepped through holes along the length direction; one set of the pressing component is arranged in each stepped through hole. According to a method, a plurality of groups of pressing components are used for vertically acting on a welded panel, and a plurality of groups of pressing load are applied, so that the welded panel can be pressed and fixed. The device disclosed by the invention has the advantages of being simple in structure, low in cost, convenient to dismount, replace and maintain and the like; the method is good in pressing effect, uniform in pressing force and high in panel correction quality; the panel can be effectively fixed; the requirements of laser tailor-welding on flatness of the pressed panel are satisfied; the welding quality are ensured not to be affected by cracking of the edge of the panel due to welding stress caused in a welding process.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Electric arc welding automatic welding equipment and welding method thereof

InactiveCN113000997ALow failure rateImprove cleanlinessWelding accessoriesStructural engineeringWeld seam

The invention discloses electric arc welding automatic welding equipment and a welding method thereof. The electric arc welding automatic welding equipment comprises a cabinet body, a supporting block and an electric arc welder, wherein the supporting block is installed on one side of the cabinet body through a bolt; a horizontal sliding rail is installed at the top of the supporting block through an arc-shaped supporting rod and a bolt; a first electric sliding block is slidably connected into the horizontal sliding rail; a movable side plate is installed on one side of the first electric sliding block through a bolt; an electric arc welder is installed on one side of the movable side plate through a bolt; a vertical sliding rail is installed on the other side of the movable side plate through a bolt; a mechanical arm is arranged on one side of the vertical sliding rail; and a welding clamp is installed at the output end of the mechanical arm through a bolt. According to the electric arc welding automatic welding equipment and the welding method thereof, the welding seam appearance quality detection function is achieved, the welding seam quality can be improved, operation is convenient, the manufacturing cost is low, the intelligent degree is high, and manpower and material resources are effectively saved.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

Pot with composite pot bottom and preparation method thereof

ActiveCN111035226AExtended service lifeTightly boundCooking-vessel materialsDomestic vesselsMetallic materialsFiller metal

The invention provides a pot with a composite pot bottom and a preparation method of the pot. The pot sequentially comprises a pot surface layer, a pot core layer and a pot bottom layer from inside tooutside. The pot surface layer and the pot bottom layer are made of metal materials, the core layer is made of a non-metal material, has the high heat conductivity direction and is parallel to the pot bottom layer, brazing filler metal is used, the pot surface layer and the pot bottom layer are welded together through the vacuum brazing technology, and the core layer is wrapped in the pot surfacelayer and the pot bottom layer and is not exposed. A heat source is adjusted by the core layer, and the temperature parallel to the pot bottom is uniform, thereby ensuring uniform temperature of thepot surface layer. The pot with the composite pot bottom is simple to operate, the used materials are easy to obtain, and the pot has good economic prospect and wide application.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

Automobile pipe fitting welding ring welding assembly device

ActiveCN112756902AEasy to fixPrevent movementWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStructural engineering

The invention relates to the technical field of assembling devices, in particular to an automobile pipe fitting welding ring welding assembly device. By arranging a pipe groove, a rotating plate, a fixing structure, a push rod, a pressing block, an extrusion groove, a moving plate clamping rod and a clamping block, an automobile pipe fitting can be conveniently fixed, and subsequent welding ring assembling of the pipe fitting is facilitated, so that the situation that the pipe fitting moves during assembly is avoided. By arranging a welding ring sleeve column, a welding ring can be conveniently sleeved with the welding ring sleeve column, welding flux can be conveniently applied on the welding ring in the follow-up process, the situation that the hands of production personnel are in contact with the welding flux is avoided, harm of the welding flux to the two hands of the production personnel is reduced, and the health of the two hands of the production personnel is protected; and by arranging a movable block, a first fixing block, a sliding block, a clamping plate, a rotating rod and a rotating block, the welding ring can be conveniently fixed, and the phenomenon that the welding quality is affected due to the fact that impurities on the two hands are transferred into the welding flux on the welding ring when the two hands of a production worker touch the welding ring is avoided.

Owner:SHAANXI RUIGE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com