Portable auxiliary supporting frame welding fixture suitable for angle steel tower installation

A technology of auxiliary support and welding fixture, used in auxiliary welding equipment, auxiliary devices, welding equipment and other directions, can solve the problems of scrap angle steel, poor welding quality, and easy generation of large gaps in angle steel, so as to achieve a wide range of applications and ensure welding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

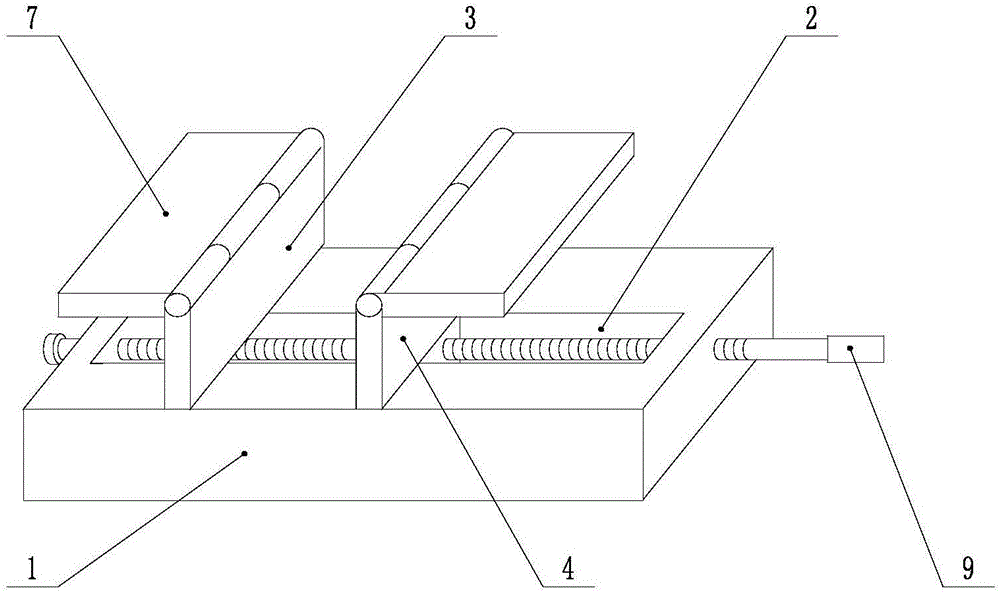

[0023] Such as figure 1 As shown, the portable auxiliary support frame welding fixture suitable for angle steel tower installation includes a base 1, a guide groove 2 is arranged on the base 1, a fixed support plate 3 is arranged at one end of the guide groove 2, and the guide groove 2 is far away from the fixed support plate 3. One end is provided with a mobile support plate 4, a moving part 5 is provided below the mobile support plate 4, a screw rod 6 is provided through the mobile part 5, the moving part 5 and the screw rod 6 are located in the guide groove 2, and the moving part 5 and the screw rod 6 are screwed together, When the screw rod 6 rotates, the moving part 5 can move along the screw rod 6 in the guide groove 2; Move, move the moving part 5 to a suitable position in the direction of the fixed support plate 3; the fixed support plate 3 and the mobile support plate 4 are hinged with a rotating support plate 7, and the rotating support plate 7 is adjusted by the rot...

Embodiment 2

[0026] This embodiment is based on Embodiment 1 to further illustrate the present invention.

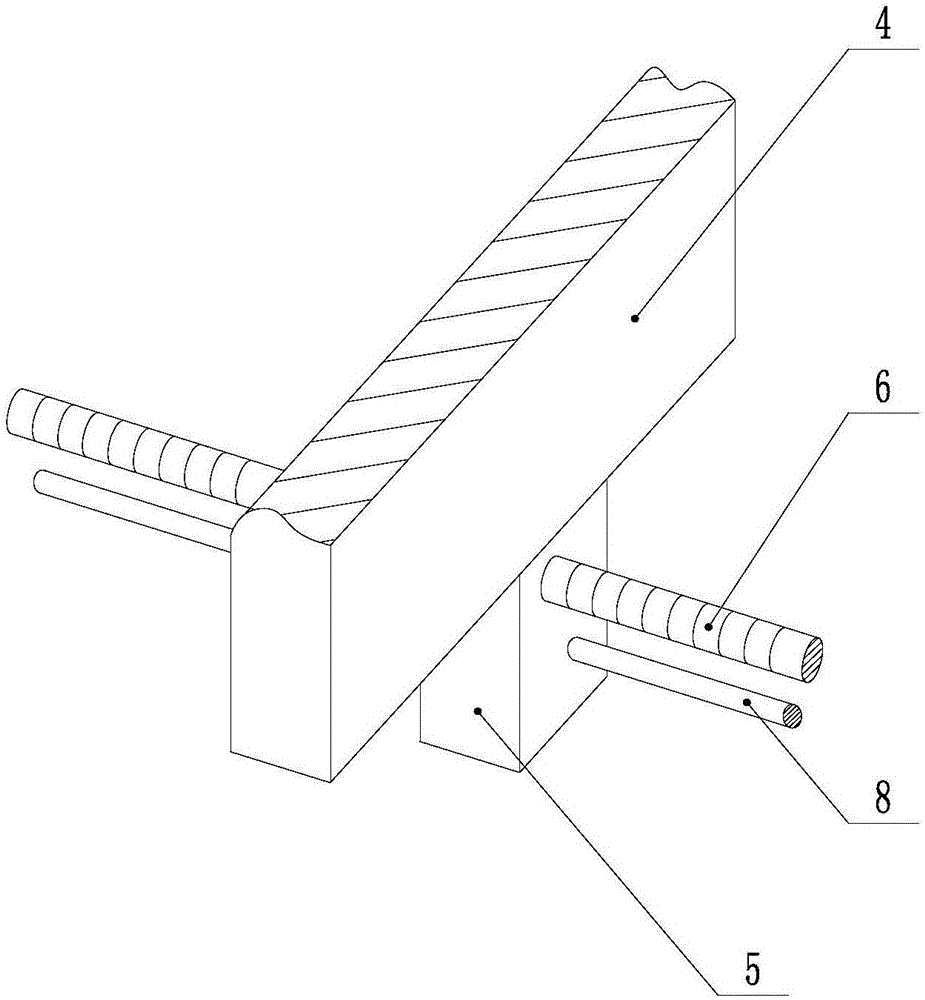

[0027] Such as figure 2 As shown, the portable auxiliary support frame welding fixture suitable for angle steel tower installation, the moving part 5 is also provided with a guide rod 8, the screw rod 6 and the guide rod 8 are parallel to each other, and the guide rod 8 plays a guiding role, so that the moving part 5 and the guide rod 8 are parallel to each other. The movement of the mobile support plate 4 is more stable, and the position of the fixed support plate 3 and the mobile support plate 4 changes greatly during welding, resulting in poor final welding quality and even the scrapping of the angle steel.

Embodiment 3

[0029] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0030] Portable auxiliary support frame welding fixture suitable for angle steel tower installation, the screw 6 is connected with a driving device (not shown in the figure), the driving device drives the screw 6 to rotate, reducing labor intensity, the driving device can choose a motor; the driving device is connected with a control A controller (not shown in the figure) controls the speed and direction of the driving device. The controller can be a common PLC controller on the market, and can realize the control of the driving device through the control method in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com