Pot with composite pot bottom and preparation method thereof

A technology for cookware and bottom layer, which is applied to the cookware with a composite bottom and the field of preparation thereof, and achieves the effects of wide application fields, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the pan with the composite pan bottom is as follows:

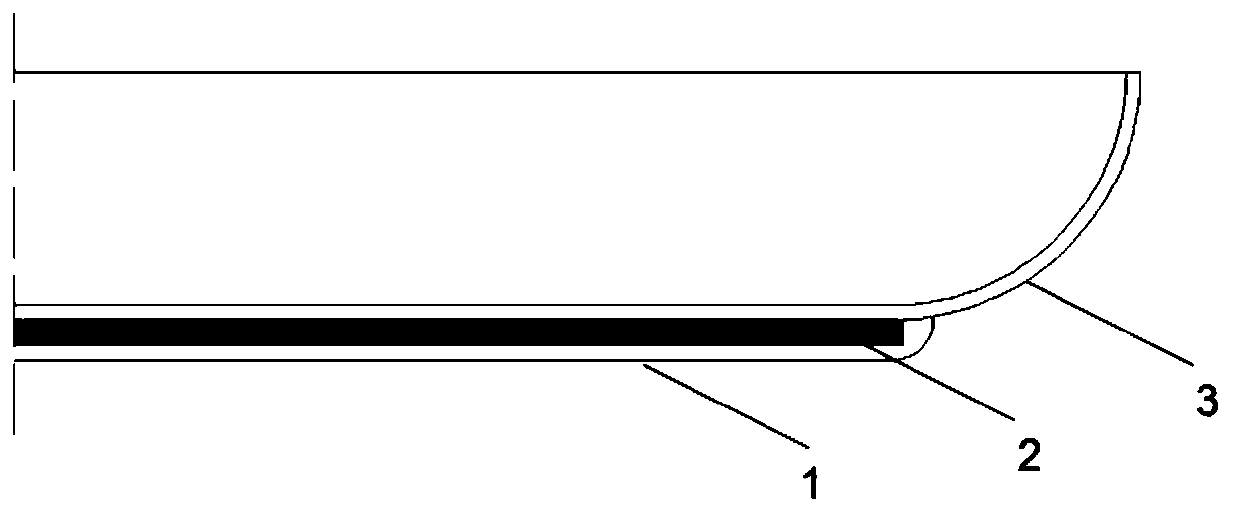

[0032] 1) Select a piece of 150×150×3mm 304# stainless steel plate and cut it into a disc with a diameter of 120mm and a thickness of 3mm; stamp the stainless steel disc to form a bottom plane diameter of 96mm with a concave surface layer of the pot;

[0033] 2) Take another piece of 150×150×2mm 304# stainless steel plate, cut it into a disc with a diameter of 100mm and a thickness of 2mm, and punch it into a pot bottom with a bottom plane diameter of 94mm and a concave surface;

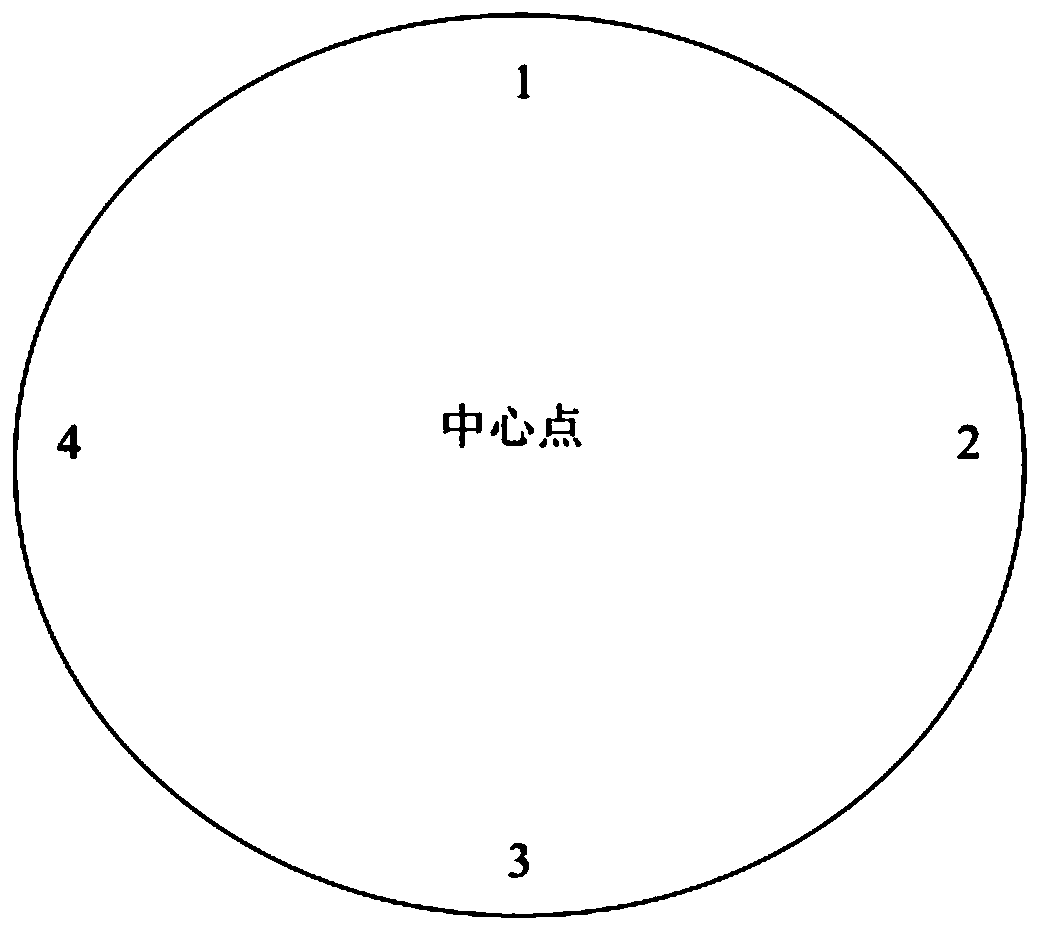

[0034] 3) Select a 100×100×2mm anisotropic graphite sheet and cut it into a graphite disc with a diameter of 90mm and a thickness of 2mm as the core layer of the cooker;

[0035] 4) Stack the surface layer, the core layer and the bottom layer of the pan together in turn, the bottom layer of the pan wraps the core layer so that the graphite core layer is not exposed, and is close to the edge of the bottom of the p...

Embodiment 2

[0039] The preparation process of the pan with the composite pan bottom is as follows:

[0040]1) Select a piece of 150×150×3mm 304# aluminum alloy plate and cut it into a disc with a diameter of 120mm and a thickness of 3mm; punch the aluminum alloy disc to form a bottom plane diameter of 96mm with a concave surface layer ;

[0041] 2) Take another piece of 150×150×2mm 304# stainless steel plate, cut it into a disc with a diameter of 100mm and a thickness of 2mm, and punch it into a pot bottom with a bottom plane diameter of 94mm and a concave surface;

[0042] 3) Select a 100×100×2mm anisotropic graphite sheet, cut it into a graphite disc with a diameter of 90mm and a thickness of 2mm, as the core layer of the cooker;

[0043] 4) Stack the surface layer, the core layer and the bottom layer of the pan together in turn, the bottom layer of the pan wraps the core layer so that the graphite core layer is not exposed, and is close to the edge of the bottom of the pan surface lay...

Embodiment 3

[0047] The preparation process of the pan with the composite pan bottom is as follows:

[0048] 1) Select a 150×150×3mm 304# cast iron plate and cut it into a disc with a diameter of 120mm and a thickness of 3mm; press the aluminum alloy disc to form a bottom plane diameter of 96mm with a concave surface layer;

[0049] 2) Take another piece of 150×150×2mm 304# stainless steel plate, cut it into a disc with a diameter of 100mm and a thickness of 2mm, and punch it into a pot bottom with a bottom plane diameter of 94mm and a concave surface;

[0050] 3) Select a 100×100×2mm anisotropic graphite sheet, cut it into a graphite disc with a diameter of 90mm and a thickness of 2mm, as the core layer of the cooker;

[0051] 4) Stack the surface layer, the core layer and the bottom layer of the pan together in turn, the bottom layer of the pan wraps the core layer so that the graphite core layer is not exposed, and is close to the edge of the bottom of the pan surface layer;

[0052] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com