Tool for welding optical device flexible board and PCB

A technology of optical devices and soft boards, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as unreliable fixing and clamping of devices, and achieve the effects of promoting rapid development, improving welding quality, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

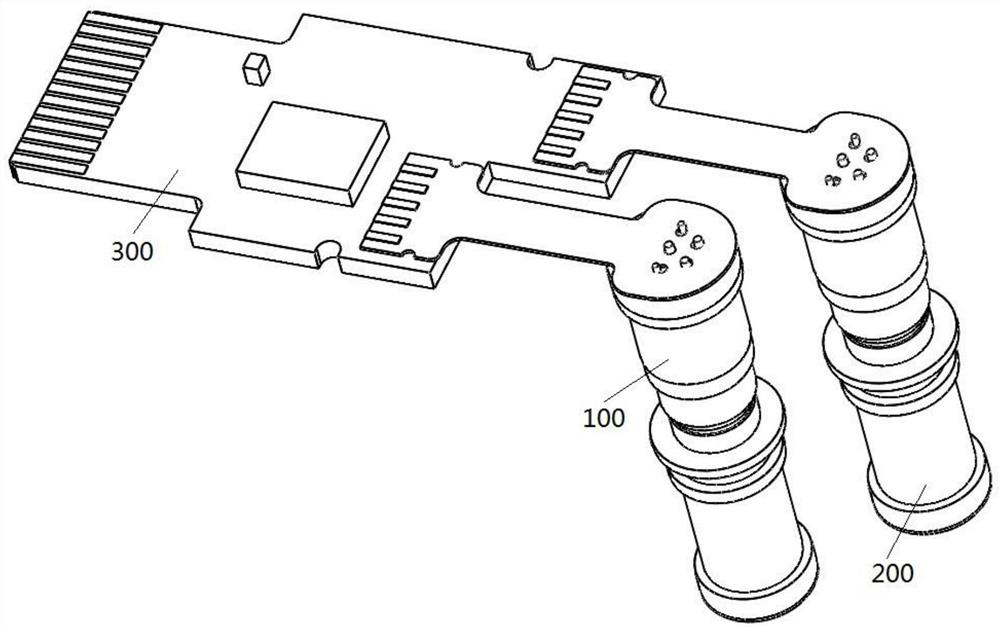

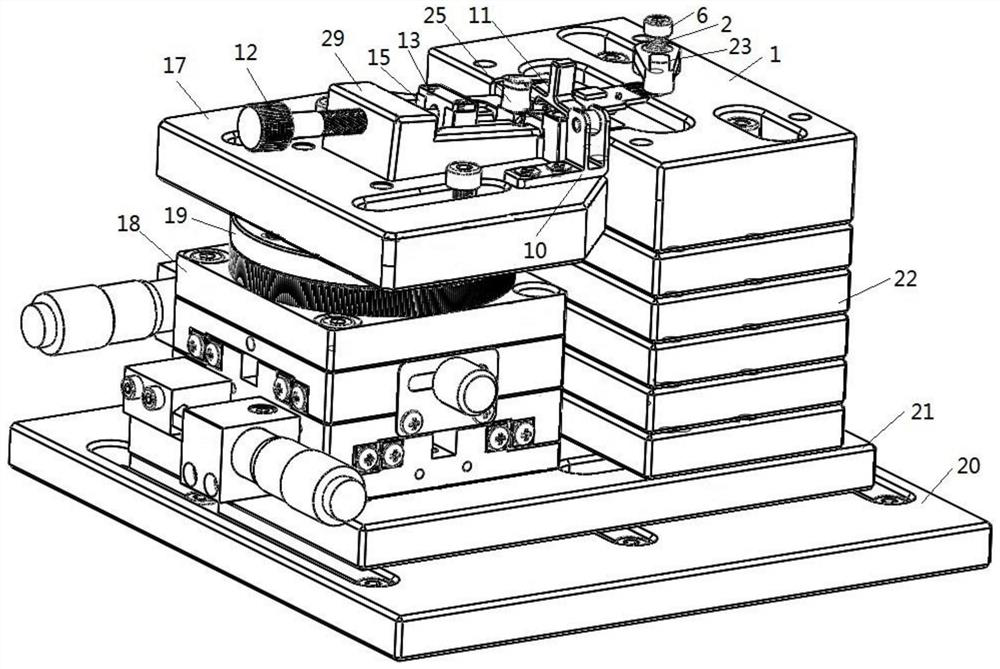

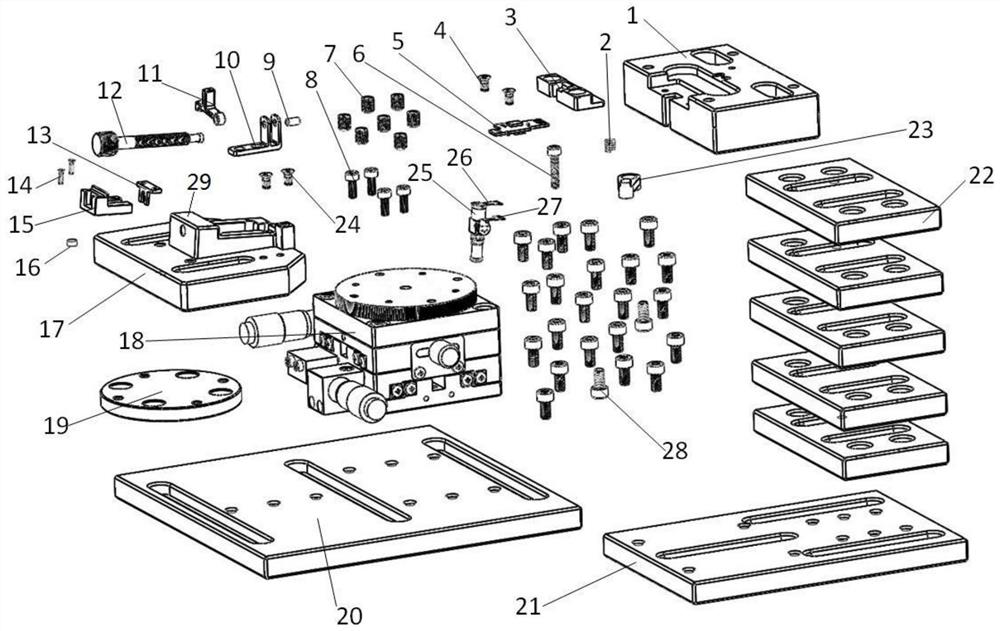

[0052] A welding tool for optical device flexible board and PCB, such as Figure 2-Figure 11 , including a bottom plate, a three-dimensional table 18, a spacer 22, a device-side card holder 17 and a PCB-side card holder 1. The welding tool is used to clamp the type A optical device 25 and weld the corresponding soft board of the optical device on the corresponding PCB5 board, wherein the soft board of the type A optical device includes the corresponding TOSA end soft board 26 and ROSA end soft board 27 .

[0053] Such as Figure 5-Figure 7 , the PCB end card holder 1 is mainly used to clamp the tail of the PCB5, and is used in conjunction with the device end card holder 17 relative to each other. After the PCB5 is installed, the optical device 25 on the PCB5 is suspended and does not interfere with the PCB socket 1. The shape, size and thickness of the PCB socket 1 are designed according to actual requirements. Specifically, such as Figure 6 , the PCB end card seat 1 is pr...

Embodiment 2

[0063] This embodiment provides a welding tool for the flexible board of the optical device and the PCB, such as Figure 12-Figure 16 , the tooling is used to horizontally clamp the B-type optical device 25 and weld the corresponding optical device soft board on the corresponding PCB5 board, wherein the B-type optical device soft board also includes the corresponding TOSA end soft board 26 and ROSA end soft board 27. When soldering B-type optical device flexible board does not need to be reshaped, its reshaped structure is as follows: Figure 14 , on the welding tooling structure and welding process, the main difference between this embodiment and embodiment 1 is:

[0064] The B-type optical device 25 is clamped in the device-side holder 17 in a horizontal clamping manner; correspondingly, in order to protect the flexible board, slotting is performed on the interference area of the flexible board on the PCB-side holder 1 . Since the soft board of type B optical device does...

Embodiment 3

[0066] This embodiment provides a welding tool for the flexible board of the optical device and the PCB, such as Figure 17-Figure 22 , the tooling is used to longitudinally clamp the C-type optical device 25 and weld the corresponding optical device soft board on the corresponding PCB5 board, wherein the C-type optical device soft board also includes the corresponding TOSA end soft board 26 and ROSA end soft board 27. When soldering the C-type optical device soft board, its shaping structure is as follows: Figure 19 , on the welding tooling structure and welding process, the main difference between this embodiment and embodiment 1 is:

[0067] The C-type optical device 25 is clamped in the device end holder 17 in a longitudinal clamping manner; accordingly, the contact surface between the slider 15 and the device will be adjusted accordingly to meet the clamping and fixing requirements. The C-type device ROSA end soft board 27 of the tooling thermocompression welding is si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com