Titanium-alloy supporting ring fusion-welding gas shield trailing cover and shielding method

A technology of gas protection and support rings, applied in the direction of welding accessories, etc., can solve the problems of huge equipment, inability to guarantee product quality, high equipment cost, etc., and achieve the effect of stable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

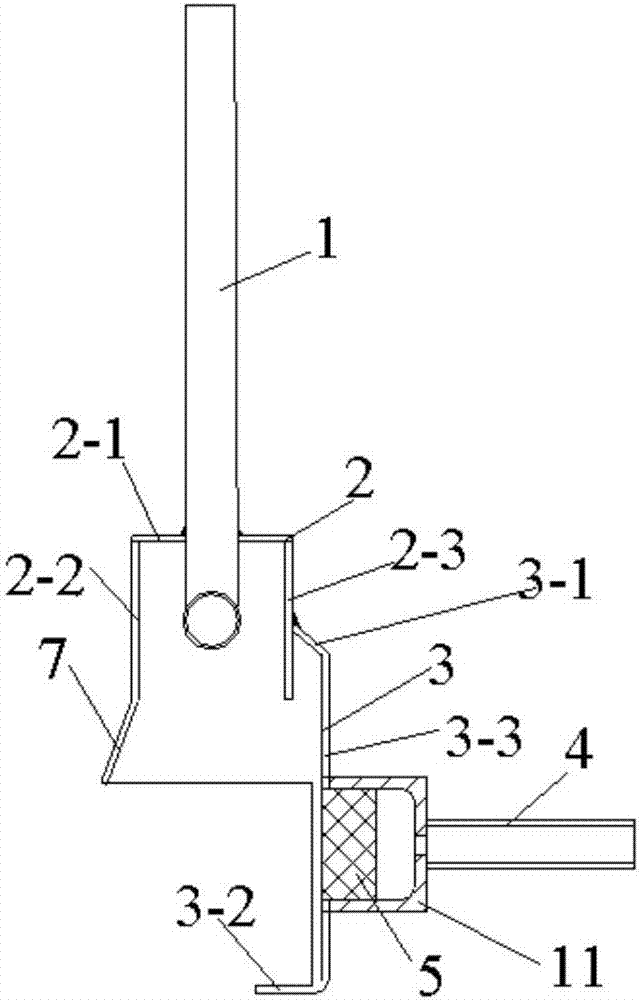

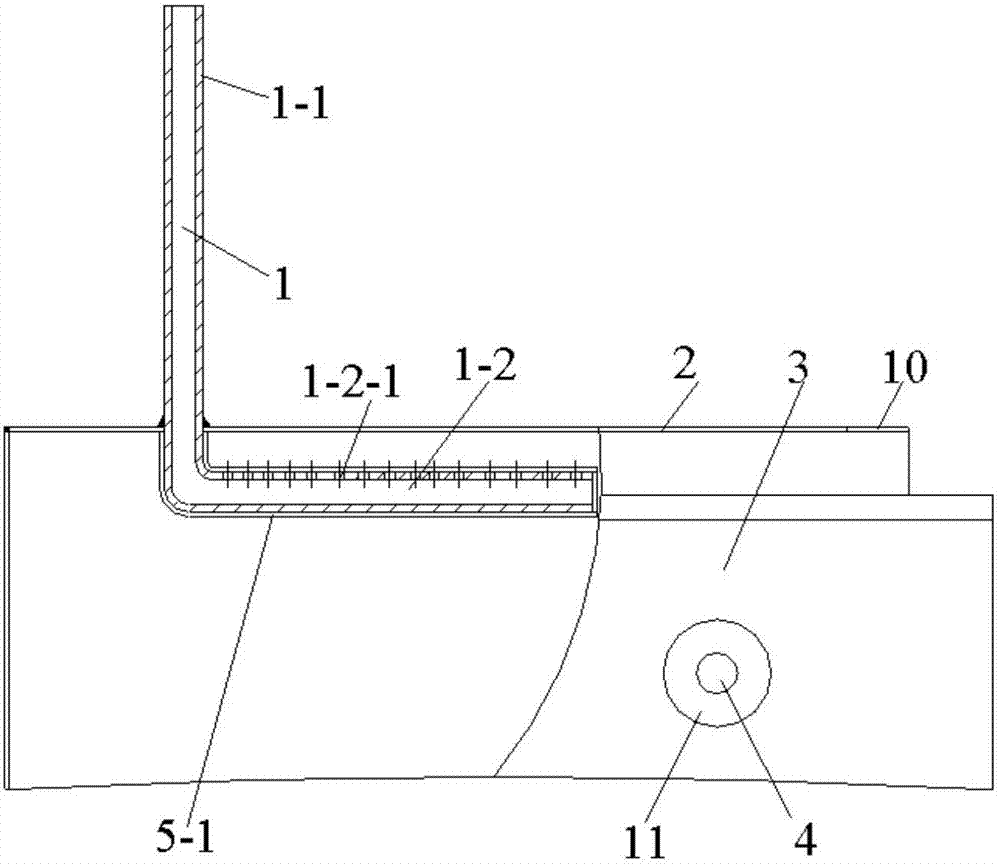

[0055] Such as figure 1 As shown, the material of the support ring is Ti230, the thickness of the butt joint is 2.4mm, the maximum height is 55mm, and the maximum profile diameter is 1043mm.

[0056] Partial gas shielding is performed on the welding process of the butt joint circumferential weld seam of the titanium alloy support ring, and the steps are as follows:

[0057] (1) Cleaning before welding:

[0058] a) Clean the fixture body 6:

[0059] Use clean gauze dipped in acetone to clean up harmful substances such as oil stains and water stains on the surface of the fixture body 6;

[0060] b) Clean up welding wire:

[0061] Polish with metallographic sandpaper to expose the metallic luster to remove the oxide film on the surface of the welding wire; and use absorbent cotton balls dipped in acetone to clean the surface of the welding wire;

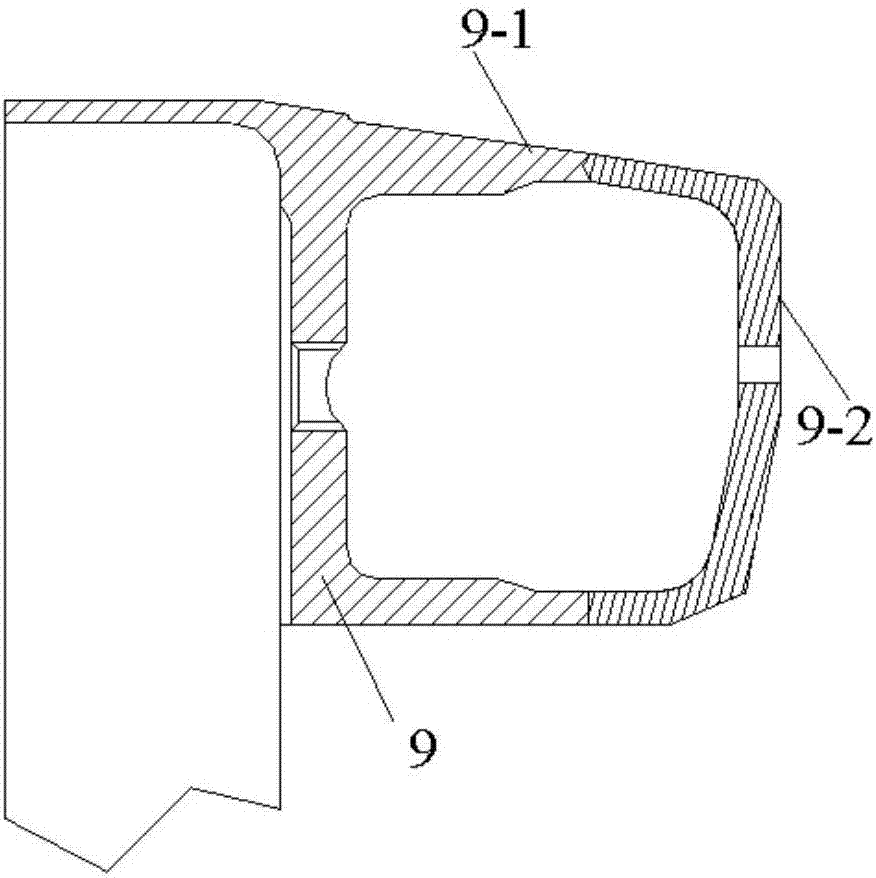

[0062] c) Clean the support ring 9:

[0063] Since the support ring 9 is a machined surface, it is sufficient to clean the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com