Device for automatically removing multi-diameter stud welding ceramic ring and removing method thereof

A ceramic ring, multi-diameter technology, used in welding equipment, welding accessories, arc welding equipment, etc., to achieve the effect of large impact force and avoid excessive moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

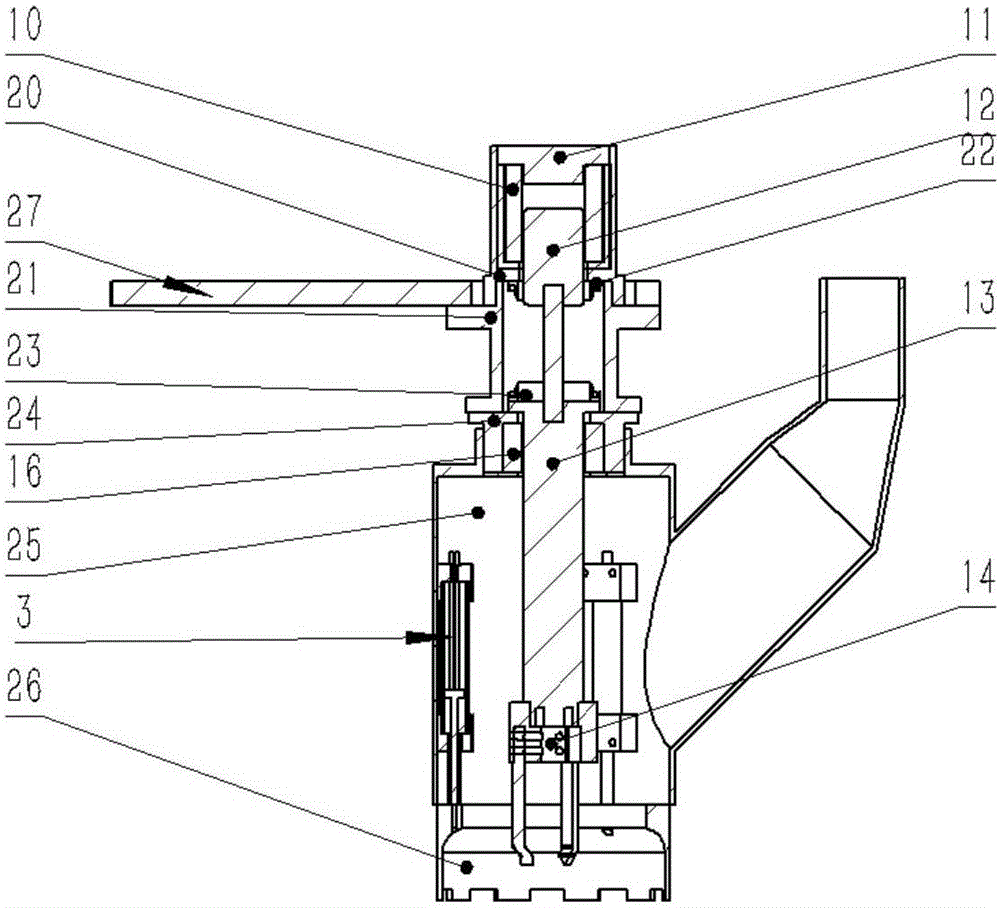

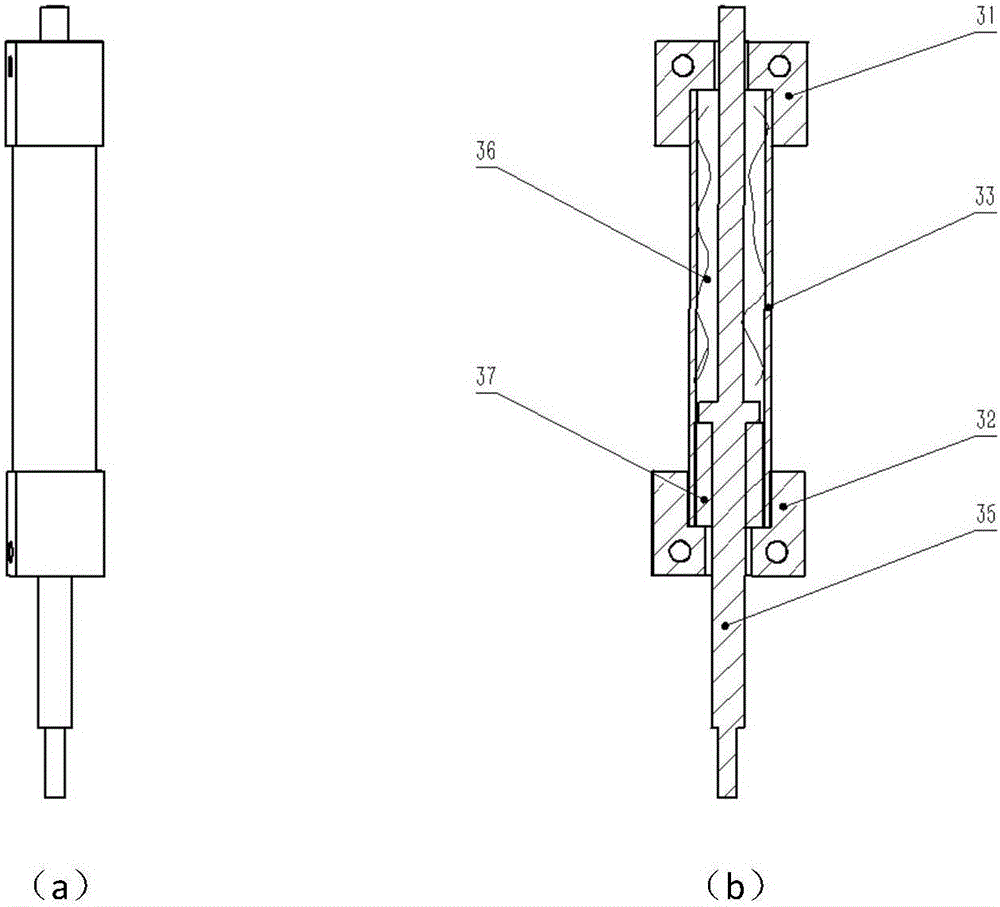

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] combine figure 1 and figure 2 , a device for automatically removing multi-diameter stud welding ceramic rings, including a fixed iron core 11, an electromagnetic coil 10, a moving iron core 12, a connecting rod 13, an upper spring sleeve 22, a lower spring sleeve 23, a spring, an upper shell 20, Middle casing 21, lower casing 24, suction tube 25, bottom barrel 26, linear bearing 16, robot connecting plate 27, ceramic ring destroying rod 14 and linkage 3.

[0023] The upper casing 20, the middle casing 21, the lower casing 24, and the suction tube 25 are fixedly connected by bolts from top to bottom in sequence. The fixed iron core 11 is located above the moving iron core 12, and the fixed iron core 11 and the moving iron core 12 are both arranged on the Inside the upper casing 20, the electromagnetic coil 10 is arranged between the moving iron core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com