Mine underground spiral water tank cleaning device

A technology of cleaning device and screw conveying device, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems of lack of promotion and popularization, and achieve the effect of convenient and fast control, safe and fast cleaning, and fast transportation of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

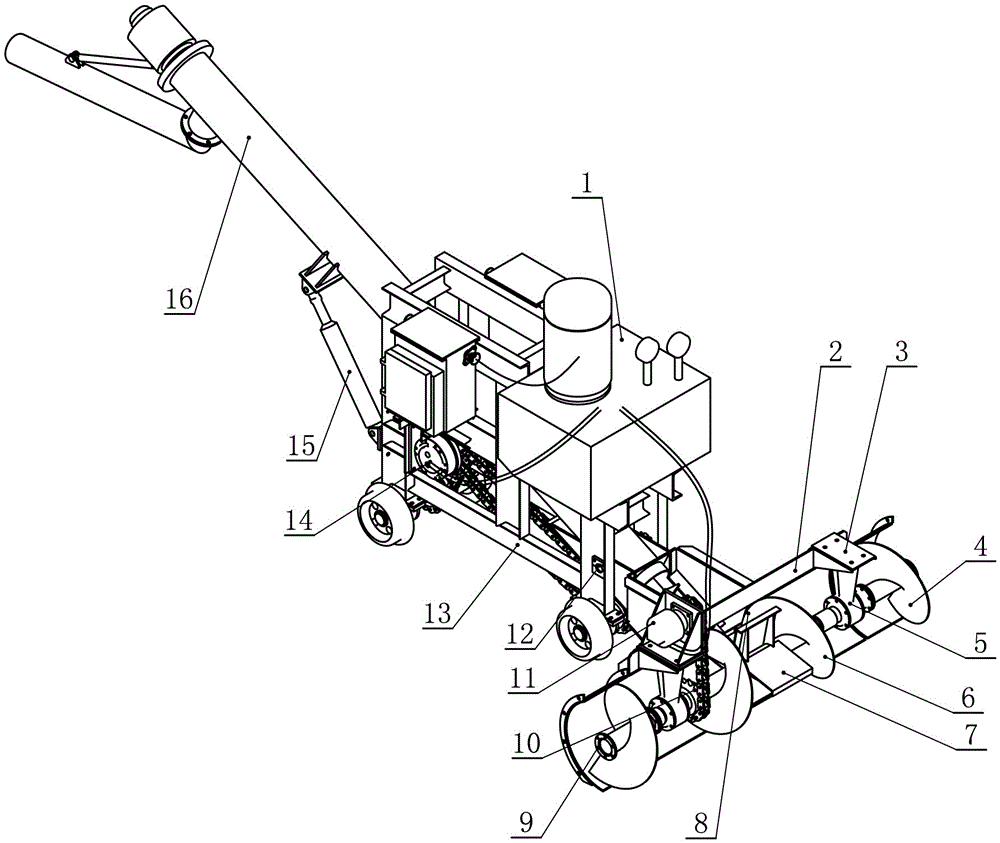

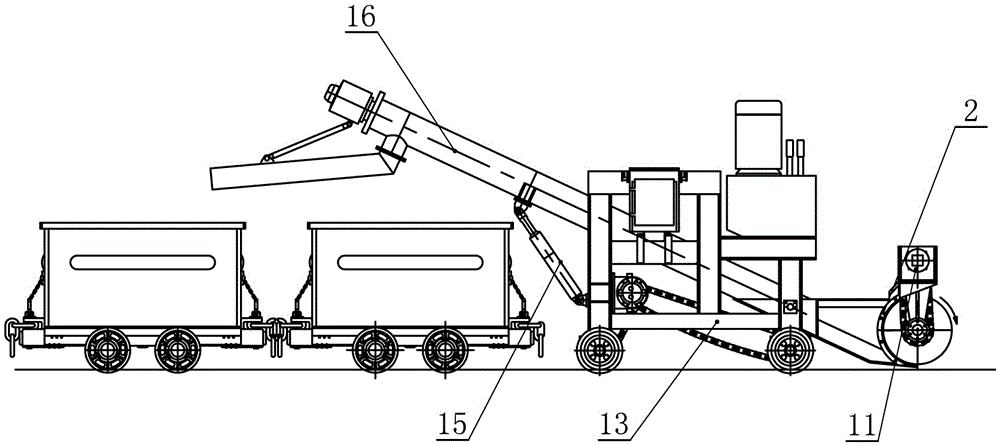

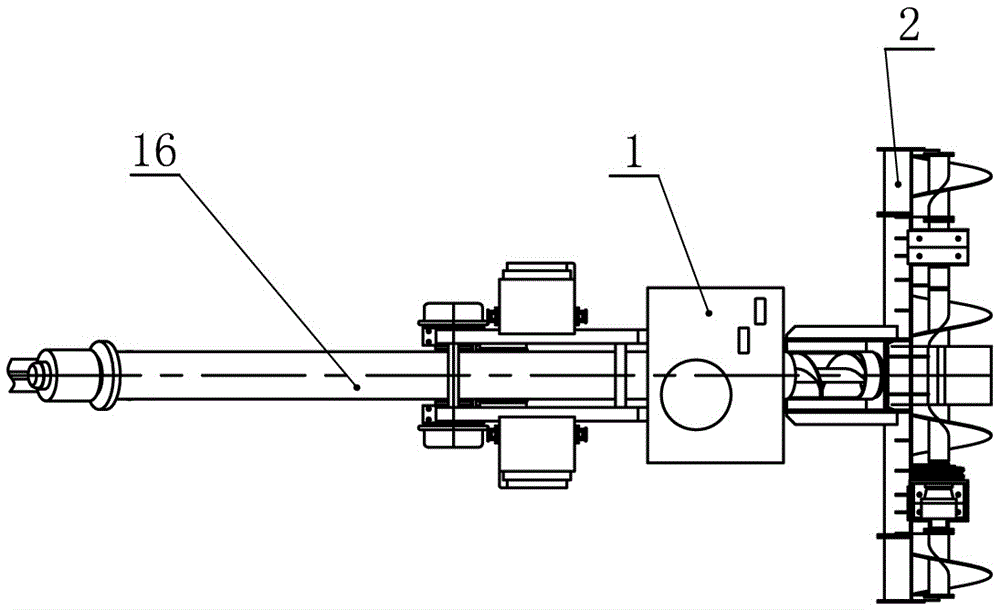

[0019] The present invention as figure 1 , 2 , Shown in 3 and 4, a mining underground spiral water tank cleaning device, including a traveling mechanism 13, the support of the traveling mechanism 13 is connected with a screw conveying device 16 through a pin shaft 12, and the spiral conveying device 16 has a conveying helical blade , which is characterized in that: the bracket of the traveling mechanism 13 is fixedly connected with a high-pressure plunger pump logic type full hydraulic control system 1 and a low-blocking parallel sprocket transmission mechanism 14, and the low-blocking parallel sprocket transmission mechanism 14 is connected with a high-pressure plunger pump logic type The full hydraulic control system 1 is connected, the front end of the screw conveying device 16 is designed with a stirring head, the stirring head is overcoated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com