Resistance spot welding process for aluminium alloy parts

A technology of aluminum alloy parts, resistance spot welding, applied in resistance welding equipment, metal processing, vehicle parts, etc., can solve the problems of product quality, production impact, impact on production efficiency, labor and material resources, etc., to ensure the quality of solder joints , Save manpower and material resources, save the effect of intermittent welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

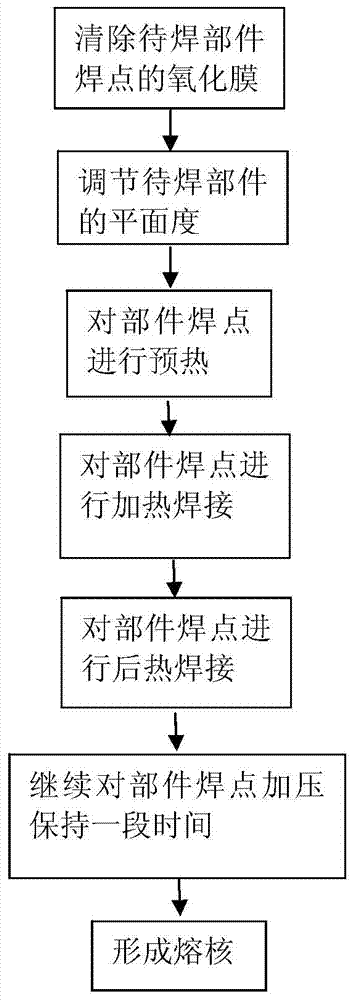

[0028] Such as figure 1 As shown, a resistance spot welding process of aluminum alloy parts of the present invention comprises: step S1, leveling the parts to be welded first, to adjust the flatness of the parts; step S2, spot welding the parts to be welded; S3, Pressurization is maintained on the component solder joints for a period of time to allow the solder joints to form a nugget.

[0029] The parts to be welded can be general aluminum alloy parts, and the welding process is especially suitable for the end wall of the car body, wherein the end wall of the car body is welded by the end wall skeleton and the end wall plate.

[0030] In order to avoid the adverse effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com