Laser transmission welding method for connecting plastic pieces

A laser transmission welding and laser welding technology, applied in the field of laser transmission welding, can solve the problems of high instantaneous power, cumbersome actual operation, limited heat transfer efficiency, etc., to achieve the effect of improving heat transfer efficiency, avoiding welding quality, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

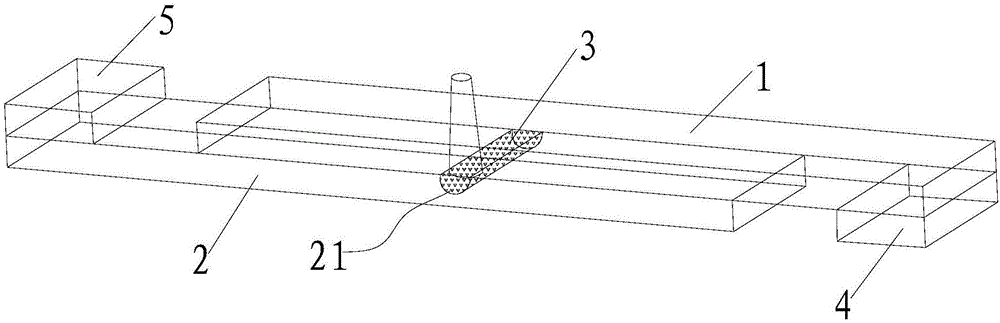

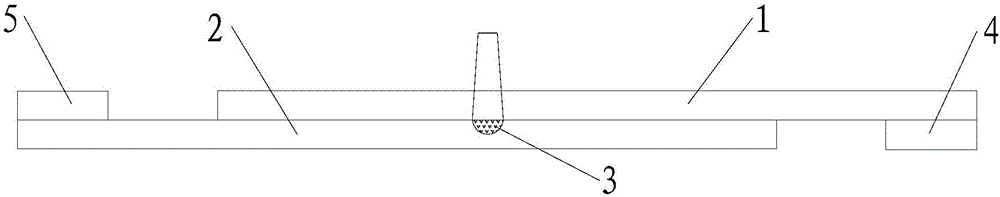

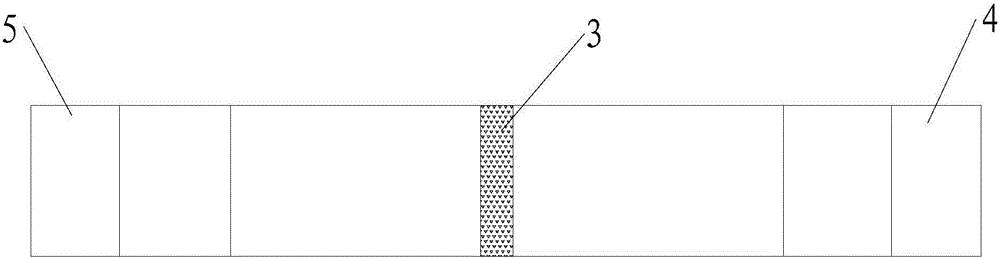

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] see Figure 1 to Figure 3 In the welding working principle diagram shown, the first plastic part 1 and the second plastic part 2 to be welded are both transparent plastic parts, in which the first plastic part 1 is located at the top, the second plastic part 2 is located at the bottom, and the laser is set at the Above a plastic part 1 , the laser beam generated by the laser passes through the first plastic part 1 from above the first plastic part 1 and projects onto the second plastic part 2 . The laser transmission welding is carried out sequentially according to the following steps:

[0034] Firstly, a groove 21 is opened at the position to be welded of the second plastic part 2. The shape of the groove 21 can be determined according to the actual production situation, and its depth is preferably 1mm-2mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com