Error compensation type laser welding equipment with crack detection function

An error compensation and laser welding technology, applied in the field of error compensation laser welding equipment, can solve the problems of staff health protection, failure to consider welding exhaust gas purification, failure to consider welding exhaust gas recovery and reuse, etc., to achieve adjustment of welding position, The effect of flexible welding positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

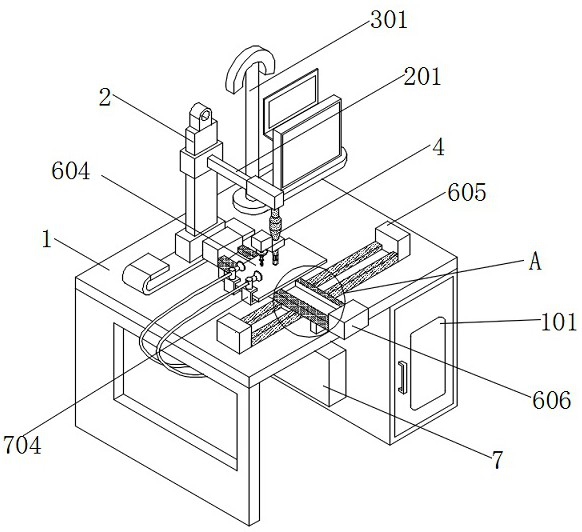

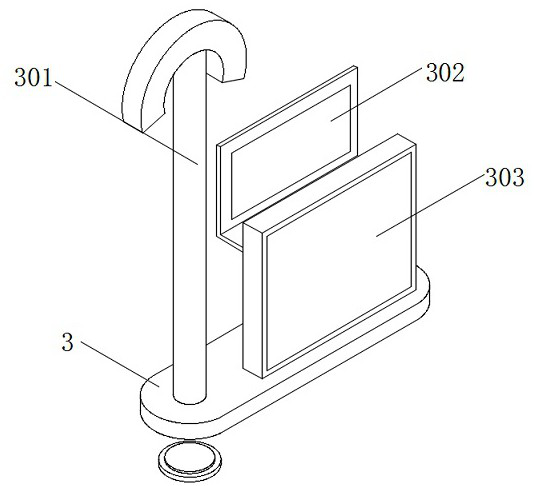

[0044] see figure 1 , image 3 and Figure 4 , an embodiment provided by the present invention: an error-compensated laser welding device with crack detection, including an operation table body 1 and a welding torch body 4, a stand 2 is installed on the top of the operation table body 1, and the stand 2 The surface of the telescopic cross bar 201 is installed, and the tail end bottom of the telescopic cross bar 201 is equipped with a welding torch body 4;

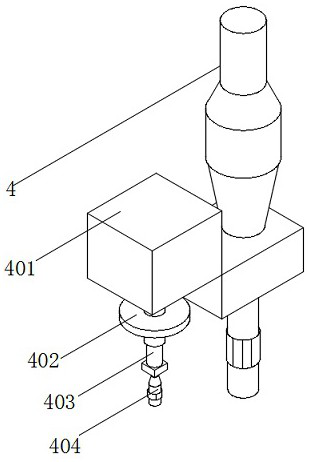

[0045] The surface of the welding gun body 4 is sleeved with an L-shaped connection block 401, and the bottom of the connection block 401 is equipped with an electric telescopic rod 403, and the electric telescopic rod 403 is located on one side of the welding torch body 4, and the surface of the electric telescopic rod 403 is socketed There is a set plate 402, a symmetrically arranged crack detector 405 is installed on the bottom of the set plate 402, a welding head 404 is installed on the bottom of the electric telescop...

Embodiment 2

[0049] see figure 1 and Figure 6 , an embodiment provided by the present invention: an error-compensated laser welding device with crack detection, including a No. 1 chute 6, and a No. 1 chute 6 is installed on the top of the operating table A No. 1 slider 601 is fitted inside, and No. 2 chute 602 is connected to the top of No. 1 slider 601, and No. 2 chute 602 is vertically arranged with No. 1 chute 6. The interior of No. 2 chute 602 is slidably installed with No. 2 slider 603, the top of No. 2 slider 603 is equipped with a rectangular welded bottom plate 604, No. 1 slider 601 and No. 2 slider 603 are magnet blocks, and No. 1 magnet is installed at both ends of No. 1 chute 6. Iron 605, the two ends of No. 2 chute 602 are equipped with No. 2 electromagnet 606.

[0050] Specifically, after one group of No. 1 electromagnets 605 is energized, No. 1 slider 601 can be driven by the electromagnetic adsorption of No. 1 electromagnet 605 to drive No. 2 chute 602 and welding bottom ...

Embodiment 3

[0053] see figure 1 and Figure 5 , an embodiment provided by the present invention: an error-compensated laser welding device with crack detection, including an adjustable support box 5, the bottom of both ends of the second chute 602 is equipped with an adjustable support box 5, the adjustable support box The top wall of 5 is equipped with electric push rods 501 equidistantly arranged, and a pressure detector 502 is installed at the bottom end of the electric push rods 501. The sensor 504 and the roller frame 503 are installed on the bottom of the pressure detector 502, and the two sets of pressure sensors are electrically connected.

[0054] Specifically, when the welding bottom plate 604 moves along the No. 2 chute 602, the gravity of the welding bottom plate 604 and the objects to be welded placed on the top will cause the center of gravity to be off when the welding bottom plate 604 moves to the two ends of the No. 2 chute 602. Move, and then make the welding bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com