ldmos transistor and method of making the same

A manufacturing method and transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of improving carrier mobility, eliminating adverse effects, and reducing short-channel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

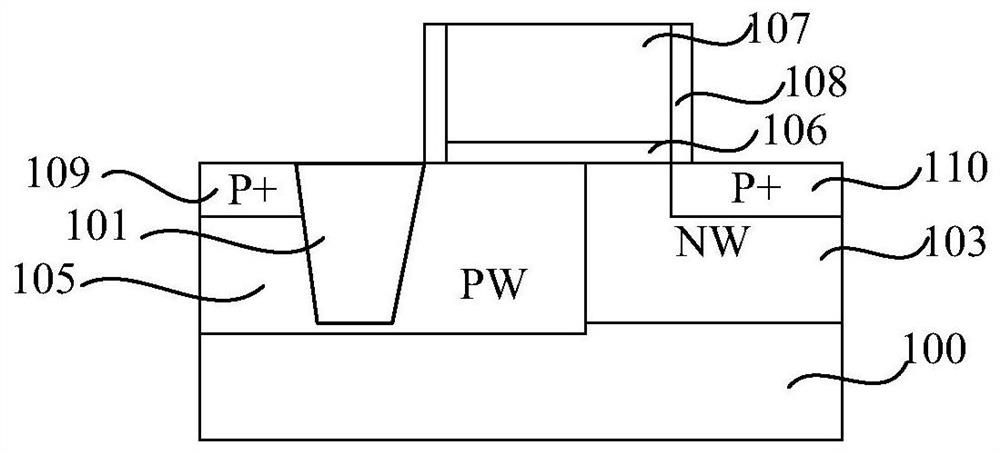

[0048] A method for manufacturing an LDMOS transistor, comprising the steps of:

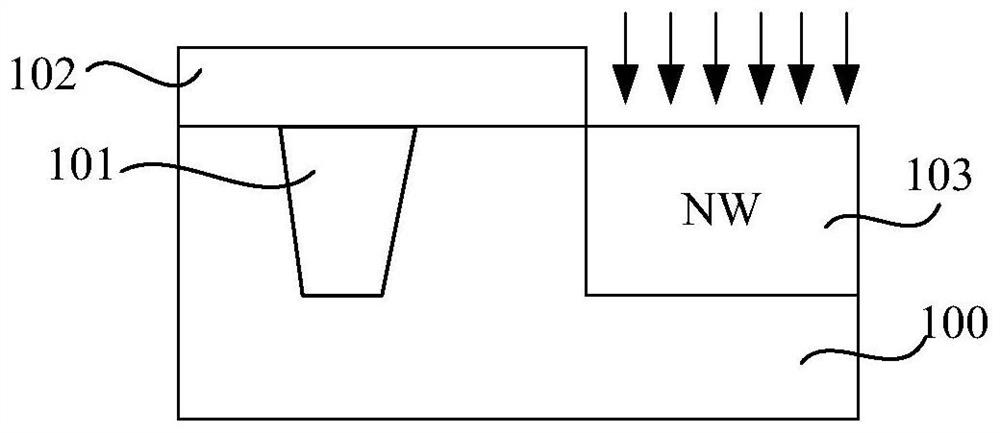

[0049] First, please refer to Figure 1A , providing a P-type semiconductor substrate 100 with a shallow trench isolation (Shallow trench isolation, STI) 101, forming a first patterned photoresist layer 102 on the surface of the semiconductor substrate 100 to expose the Ion-implanted semiconductor substrate surface regions;

[0050] Then, please continue to refer to Figure 1A , using the first patterned photoresist layer 102 as a mask, using N-type ions to perform well ion implantation on the exposed semiconductor substrate surface region, thereby forming an N well (NWELL, NW) 103;

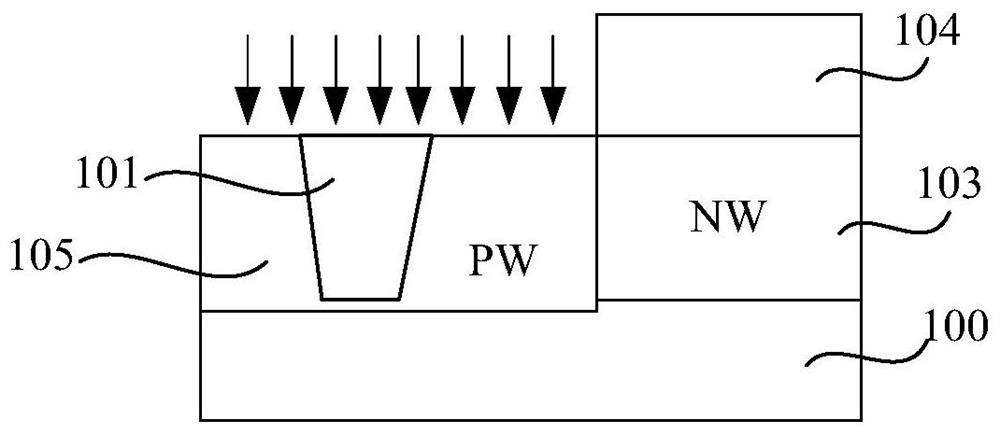

[0051] Next, please refer to Figure 1B , remove the first patterned photoresist layer 102, and form a second patterned photoresist layer 104 on the surface of the semiconductor substrate surface 100, the second patterned photoresist layer 104 covers the N well 103 And expose part of the surface area of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com