Explosion resistance and prevention device for combustible and flammable liquid and gas pipelines

A gas pipeline and flammable liquid technology, which is applied in fire rescue and other directions, can solve the problems of many influencing factors and untimely response of explosion suppression devices, and achieve the effect of preventing secondary damage and suppressing fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

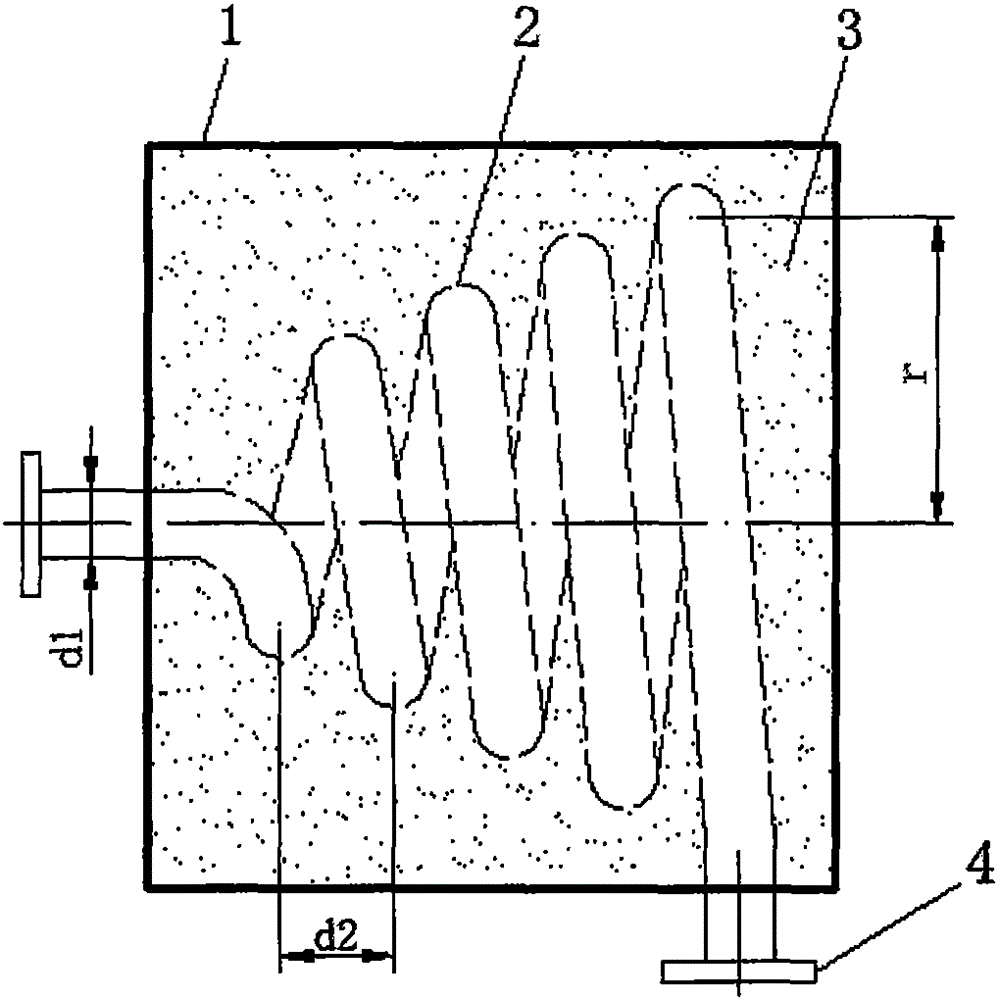

Embodiment 1

[0022] Flammable and flammable liquid and gas pipeline explosion-proof explosion-proof device, composed of conical spiral tube 2, shell 1 and fire retardant 3, conical spiral tube 2 is provided with an inlet and an outlet, conical spiral tube 2 is set in the shell 1, The inlet and outlet protrude from the casing 1 and are respectively connected to the conveying pipeline through flanges, and the gap between the casing 1 and the tapered spiral pipe 2 is filled with 0.8g / cm3 dry powder fire extinguishing agent. Due to the critical pipe diameter effect and the corner effect, the intensity of the flame and the shock wave entering the conical spiral pipe 2 will rapidly and continuously decay until they disappear, thereby achieving the effect of explosion prevention and explosion protection. When the device casing 1 is damaged by the impact of the shock wave, the filled dry powder fire extinguishing agent can be thrown out in time to form a fire extinguishing environment around the de...

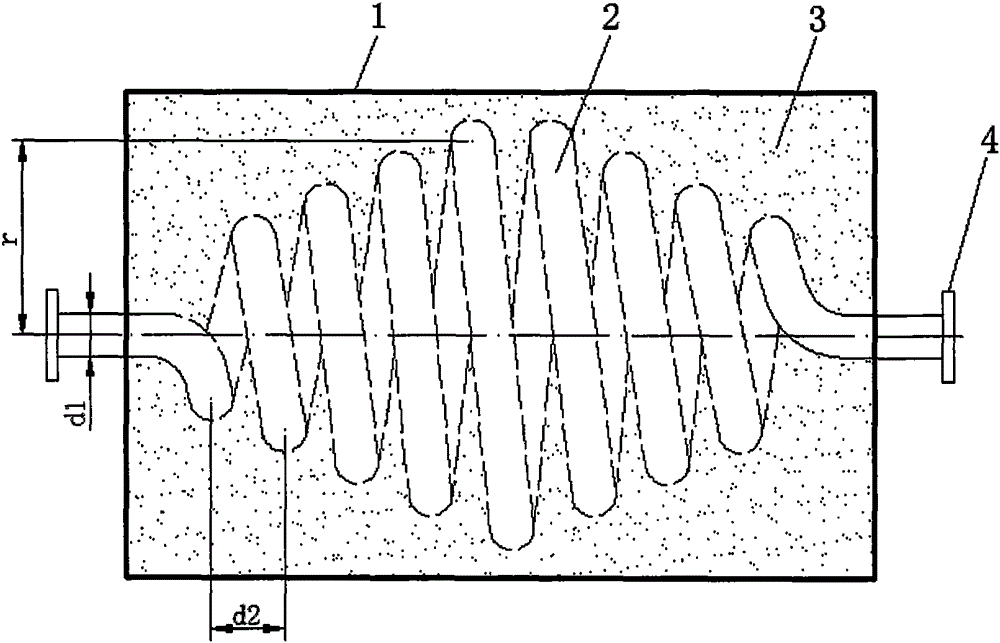

Embodiment 2

[0025] Explosion-proof and explosion-proof device for flammable and flammable liquid and gas pipelines, consisting of a double-conical spiral tube 2, a shell 1 and a fire retardant 3, the double-conical spiral tube 2 is provided with an inlet and an outlet, and the double-conical spiral tube 2 is arranged on the shell 1, the inlet and outlet extend out of the shell 1 and are respectively welded to the delivery pipeline, and the space between the shell 1 and the double-tapered spiral tube 2 is filled with 2Mpa inert gas. Due to the critical pipe diameter effect and the corner effect, the intensity of the flame and the shock wave entering the biconical spiral pipe 2 will rapidly and continuously decay until they disappear, thereby achieving the effect of explosion prevention and explosion protection. When the device casing 1 is damaged by the impact of the shock wave, the filled inert gas can be thrown out in time to form a fire extinguishing environment around the device for loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com