Q 390E class super-thick steel plate with thickness of 100mm and manufacturing method thereof

A technology of extra-thick steel plate and manufacturing method, applied in the direction of temperature control, etc., to achieve the effects of low capital investment in equipment, excellent low temperature toughness, and stable product performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

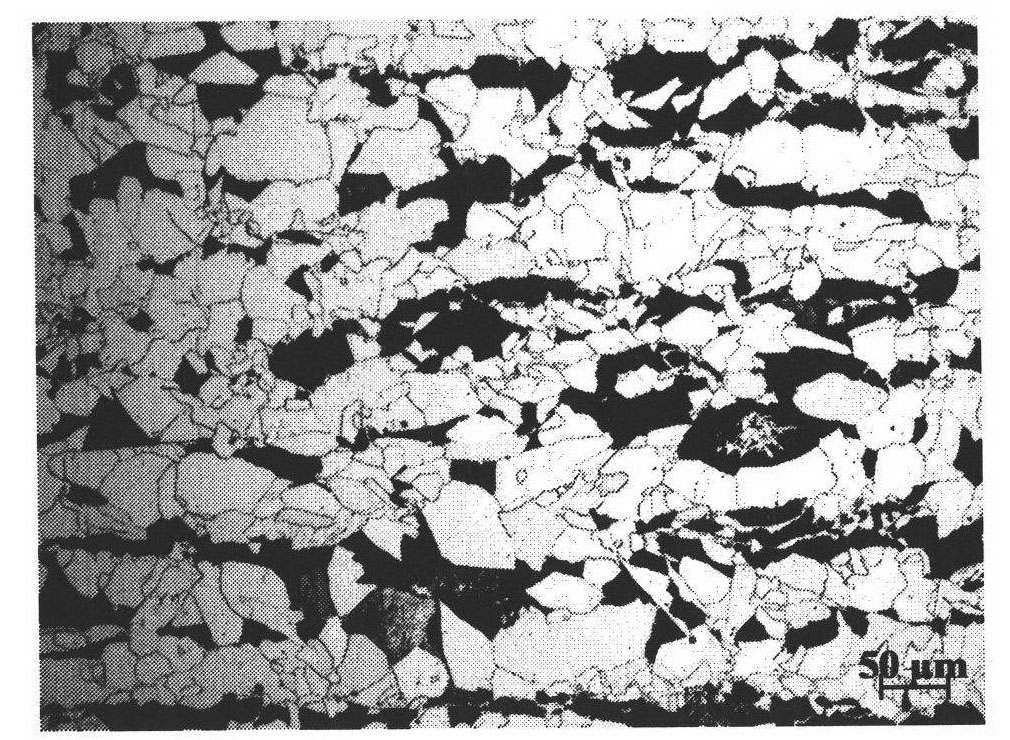

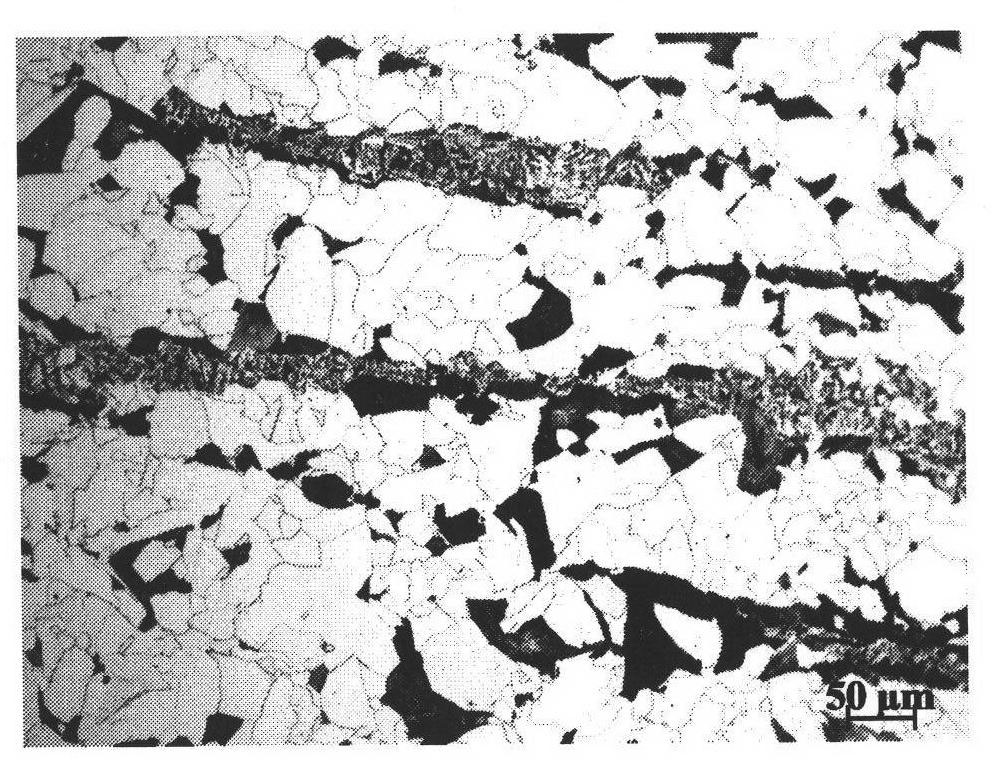

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific examples.

[0032] A 100mm thick Q390E grade extra-thick steel plate, the chemical composition weight percentage of the steel in the steel plate is: C: 0.08-0.13%, Mn: 1.20-1.60%, Si: 0.10-0.25%, P: ≤0.015%, S: ≤ 0.005%, Ni: 0.10-0.40%, Nb: 0.010-0.030%, V: 0.020-0.050%, Al: 0.020-0.040%, and the balance is Fe and unavoidable impurities. The weight percentages of the chemical components of C, Nb and V in the steel conform to the following ratio relationship: 0.26%≤C+6Nb+4V≤0.40%.

[0033] A method for manufacturing 100mm thick Q390E grade extra-thick steel plate, the method adopts the following controlled rolling and controlled cooling process:

[0034](1) Continuous casting slab heating process: the heating temperature of the continuous casting slab with a thickness of 260mm is 1220-1260°C, the temperature of the soaking section is 1200-1240°C, and the heating time in the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com