Preparation and application of composite straw glass fiber inorganic material decorative integrated plate

A technology for glass fiber filaments and straw fiber filaments is applied in the field of decorative materials, which can solve the problems of low alkali cost of materials, poor environmental protection, short and disordered glass fibers, etc., and achieve the effects of stable shrinkage, good environmental protection, and good shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment discloses a composite straw glass fiber silk inorganic material decorative integrated board that can be applied to indoor and outdoor engineering decoration, especially in high humidity environment. The preparation of the integrated board includes the following steps:

[0025] (1) Knead the alkalized and softened stalks to grow 3 cm straw fiber filaments; use NaOH and industrial salt for alkalization and softening treatment respectively.

[0026] (2) Disperse with a disperser and treat with a coupling agent KH550 to obtain a random medium-alkali glass fiber with a length of 5 cm; the consumption of the coupling agent is 0.2%.

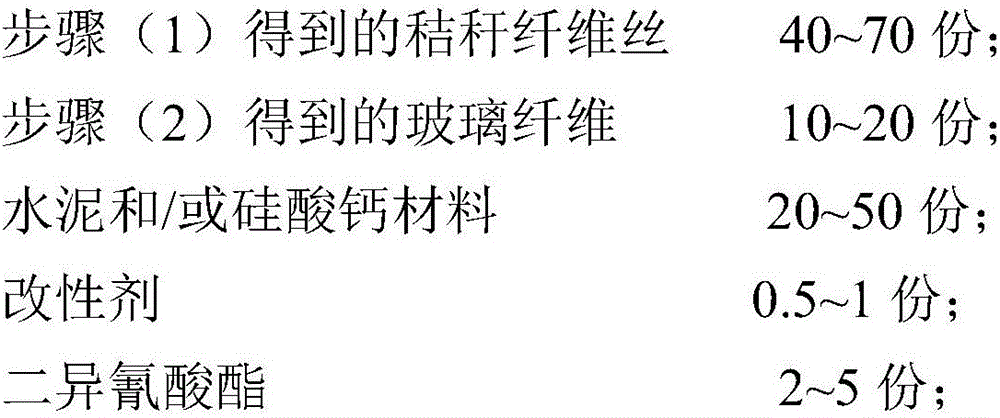

[0027] (3) Mix the raw materials according to the following weight ratio, and pre-press to obtain the straw fiber silk inorganic blank:

[0028]

[0029] (4) Lay the decorative paper impregnated with melamine resin on the surface layer of the stainless steel rust formwork, pave the pre-pressed straw fiber silk inorganic blank i...

Embodiment 2

[0032] This embodiment discloses a composite straw glass fiber filament inorganic material decorative integrated board that can be applied in the cabinet and bathroom environment. The preparation method of the integrated board includes the following steps:

[0033] (1) Knead the alkalized and softened stalks to grow 10 cm straw fiber filaments; use NaOH and industrial salt for alkalization and softening treatment respectively.

[0034] (2) Disperse with a disperser and treat with coupling agent KH550 to obtain random medium-alkali glass fibers with a length of 1 cm; the amount of coupling agent is 0.5%.

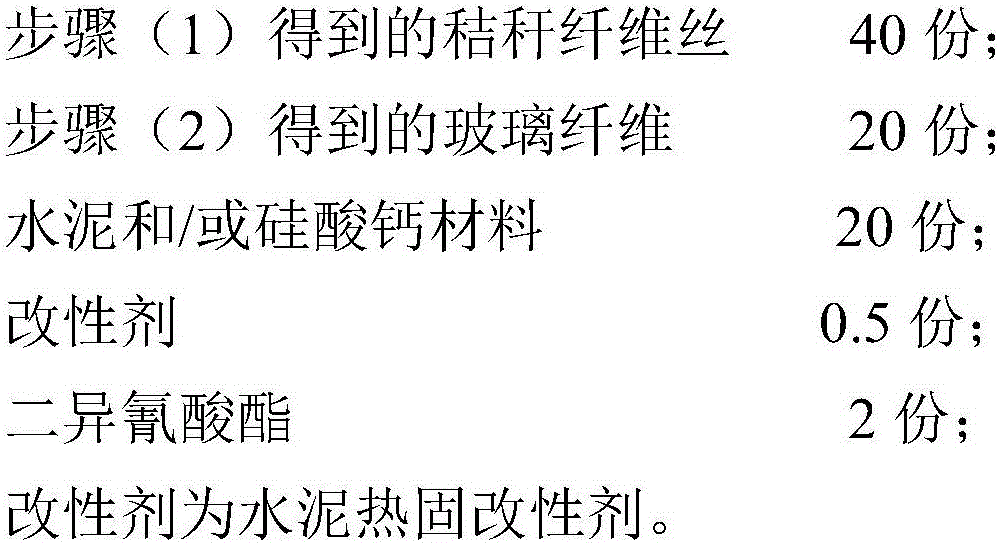

[0035] (3) Mix the raw materials according to the following weight ratio, and pre-press to obtain the straw fiber silk inorganic blank:

[0036]

[0037]

[0038] (4) Lay the decorative paper impregnated with melamine resin on the surface layer of the stainless steel rust formwork, pave the pre-pressed straw fiber silk inorganic blank in the middle of the stainless stee...

Embodiment 3

[0041] This embodiment discloses a composite straw glass fiber filament inorganic material decorative integrated board that can be applied in the cabinet and bathroom environment. The preparation method of the integrated board includes the following steps:

[0042] (1) Knead the alkalized and softened stalks to grow 7cm long straw fiber filaments; use NaOH and industrial salt for alkalization and softening treatment respectively.

[0043] (2) Disperse with a disperser and treat with coupling agent KH550 to obtain random medium-alkali glass fibers with a length of 3 cm; the amount of coupling agent is 0.4%.

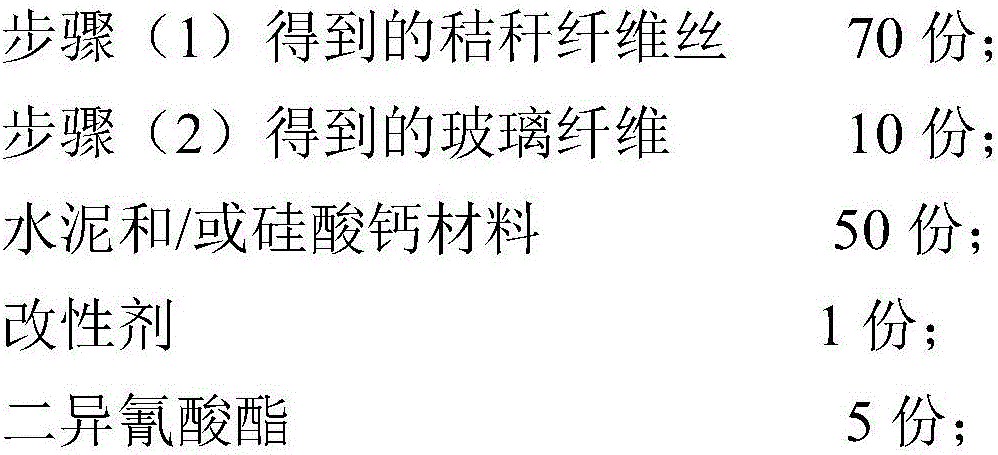

[0044] (3) Mix the raw materials according to the following weight ratio, and pre-press to obtain the straw fiber silk inorganic blank:

[0045]

[0046] (4) Spread the decorative paper impregnated with melamine resin on the surface layer of the stainless steel rust formwork, pave the pre-pressed straw fiber silk inorganic blank in the middle of the stainless steel rust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com