Multifunction formboard

A multi-functional, formwork technology, applied in the fields of formwork/formwork components, on-site preparation of building components, sustainable waste disposal, etc., it can solve the problems of pan-frost, moisture absorption, etc., and achieve increased reuse rate and wide range of uses. , Good nail grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Next, specific embodiments of the present invention will be introduced.

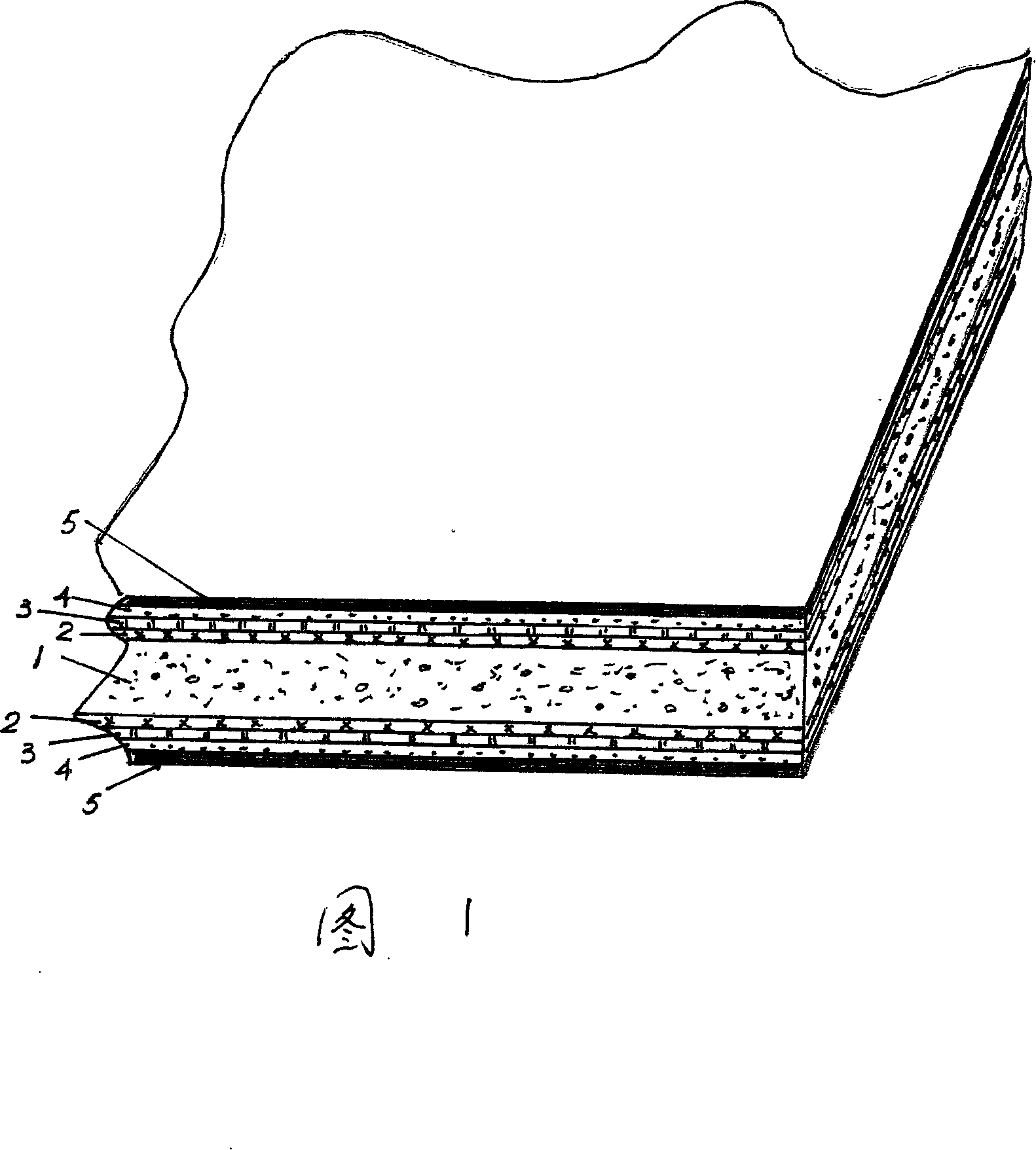

[0018] The plate is a layered symmetrical structure, the center of which is the central structural layer (1), and the forming layer (2) and the reinforcing layer (3) are respectively symmetrically distributed above and below the central structural layer (1), and the central structural layer (1) According to the weight of the layer, the raw material formula includes 17-22% of magnesium oxide, 8-12% of magnesium chloride, 18-22% of fly ash, 25-35% of sawdust or straw chips, 10-15% of water, and 0.5-15% of additives. 1%, 2% to 4% resin, the material of the forming layer (2) is glass fiber mesh cloth, the raw material formula of the reinforcing layer (3) by weight of the layer includes 28% to 35% of magnesium oxide, 15% to 25% of magnesium chloride, Calcium carbonate powder 20-25%, water 15-20%, additives 0.5-1%, resin 2-4%.

[0019] In addition: the waterproof layer (4) and the anti-friction layer (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com