Novel laminated wood and manufacturing method thereof

A technology of glulam and manufacturing method, applied in the direction of manufacturing tools, wood processing utensils, and the joining of wooden veneers, can solve problems such as the problem of floor stability that cannot be well solved, and achieve rational utilization, not easy to deform, The effect of reducing the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

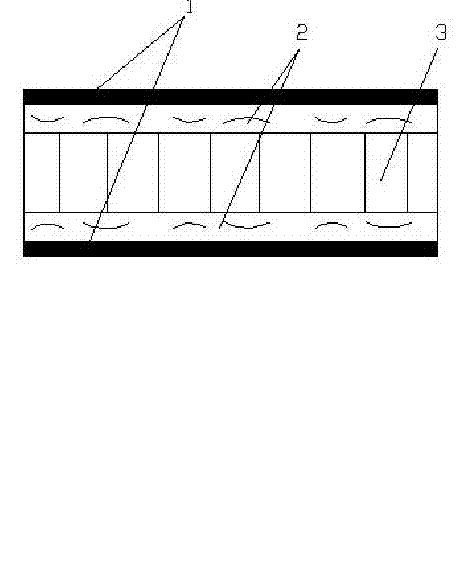

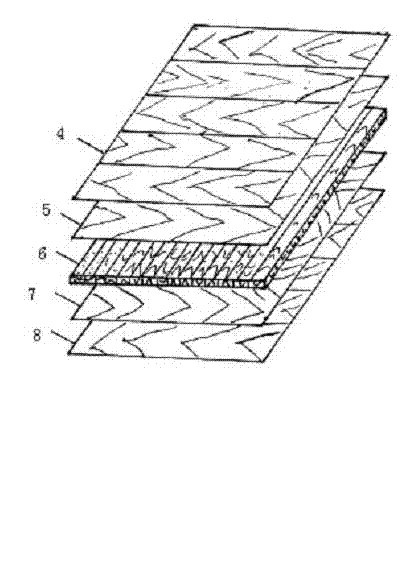

[0039] A. Production of glulam layer: According to the existing technology, a single-layer glulam with a specification of 2480mm×(407~415)mm×18mm is produced, and the prepared glulam is glued with an adhesive to form a specification of 2480mm×(407~415)mm × (360-540) mm glulam board square, after slicing the glulam board square into a glulam layer with a thickness of 0.1mm;

[0040] B. Production of poplar veneer: according to the prior art, poplar veneer with a thickness of 1 mm is obtained by rotary cutting;

[0041] C. Production of Chinese fir core board: split and cut the Chinese fir square material by sawing machine, remove bark, dead knots and other defects, and obtain the specification of (200-600) mm×(20-100) mm×(14-15) mm The fir strips are planed and thickened by four-sided planing, and then finger-jointed and lengthened by a comb-tooth tenon joint machine, and then the spliced fir strips are widened by a jigsaw machine to obtain a specification of 2460mm× 1230...

Embodiment 2

[0048] A. Production of glulam layer: According to the existing technology, a single-layer glulam with a specification of 2480mm×(305~312)mm×20mm is produced, and the prepared glulam is glued with an adhesive to form a specification of 2480mm×(305~312)mm × (400-600) mm glulam board square, after slicing the glulam board square into a glulam layer with a thickness of 1mm;

[0049] B. Production of poplar veneer: according to the prior art, the poplar veneer with a thickness of 1.5 mm is obtained by rotary cutting;

[0050] C. Fabrication of the fir core board: cut the fir square material by sawing machine, remove bark, dead knots and other defects, and obtain the specification of (400-2500) mm×(20-100) mm×(16-17) mm The fir strips are planed and thickened by four-sided planing, and then finger-jointed and lengthened by a comb-tooth tenon joint machine, and then the spliced fir strips are widened by a jigsaw machine to obtain a specification of 2480mm× 1245mm fir core laye...

Embodiment 3

[0056] A. Production of glulam layer: According to the existing technology, a single-layer glulam with a specification of 2480mm×(407~415)mm×16mm is produced, and the prepared glulam is glued with an adhesive to form a specification of 2480mm×(407~415)mm × (320~480) mm glulam board square, after slicing the glulam board square into a glulam layer with a thickness of 0.15mm;

[0057] B. Production of poplar veneer: according to the prior art, the poplar veneer with a thickness of 0.6 mm is obtained by rotary cutting;

[0058] C. Fabrication of the fir core board: cut the fir square material by sawing machine, remove bark, dead knots and other defects, and obtain the specification of (200-600) mm×(20-100) mm×(10-11) mm The fir strips are planed and thickened by four-sided planing, and then finger-jointed and lengthened by a comb-tooth tenon joint machine, and then the spliced fir strips are widened by a jigsaw machine to obtain a specification of 2480mm× 1260mm fir core la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com