Low-combustion-heat polyvinyl chloride composite and preparing method thereof

A polyvinyl chloride and composite material technology, applied in the field of fireproof building materials, can solve the problems of inapplicable polymer composite materials, many components in a flame retardant system, low water loss decomposition temperature, etc., achieving simple formula and process, avoiding mechanical properties. The effect of poor and high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

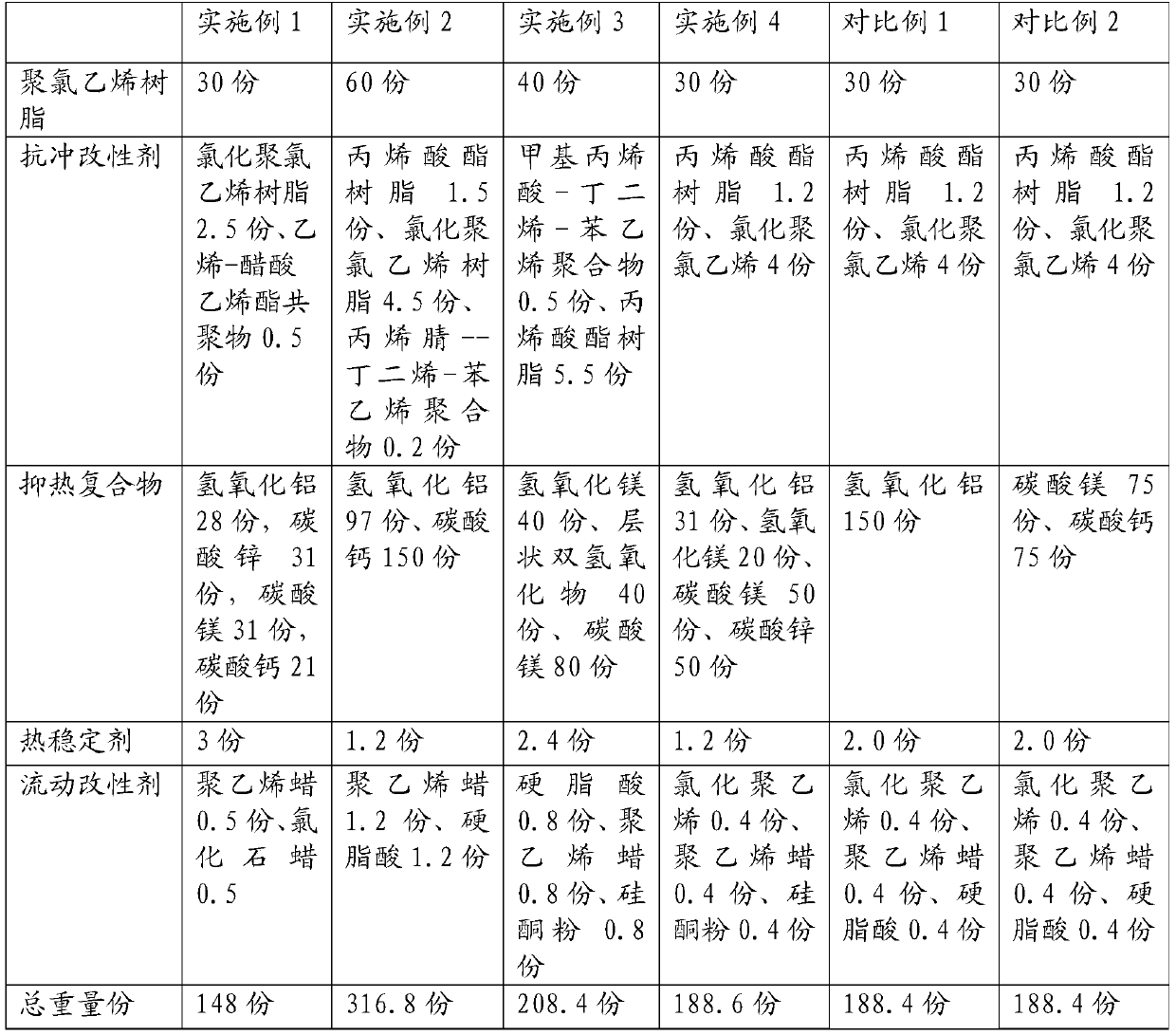

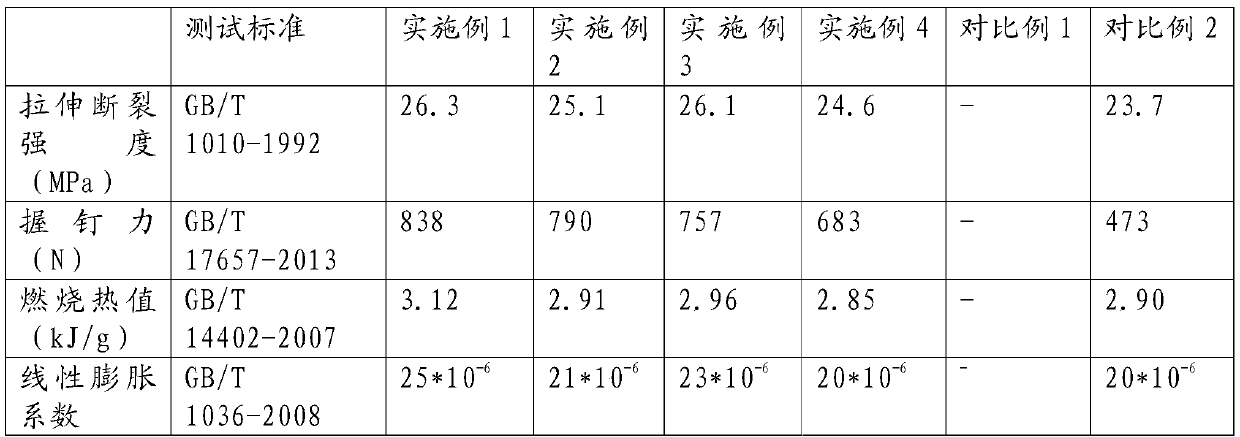

Examples

Embodiment 1

[0032] 1) Dry 28 parts of aluminum hydroxide (1 μm), 31 parts of zinc carbonate (30 μm), 31 parts of magnesium carbonate (30 μm), and 21 parts of calcium carbonate (50 μm) at 110° C. for 2 hours to remove moisture; Use as a heat suppressing compound.

[0033] 2) Add the above heat-suppressing compound with 30 parts of polyvinyl chloride resin, 2.5 parts of chlorinated polyvinyl chloride resin, 0.5 parts of ethylene-vinyl acetate copolymer, 3 parts of heat stabilizer, 0.5 parts of polyethylene wax, chlorinated polyvinyl chloride resin Put 0.5 parts of paraffin into a high-speed mixer, and under the action of high-speed stirring at 1300rpm, raise the temperature of the raw material to 120°C, then change to 650rpm and stir at a low speed, under the action of cooling water and stirring, reduce the temperature of the raw material to 50°C, and then at 200rpm The material is discharged at a low speed to complete the premixing of PVC mixture.

[0034] 3) Melt and blend the pre-mixed ...

Embodiment 2

[0036] 1) Dry 97 parts of aluminum hydroxide (3μm) and 150 parts of calcium carbonate (50μm) at 80°C for 3 hours to remove moisture; then use it as a heat-inhibiting compound.

[0037] 2) Then mix the above-mentioned heat-suppressing compound with 60 parts of polyvinyl chloride resin, 1.5 parts of acrylate resin, 4.5 parts of chlorinated polyvinyl chloride resin, 0.2 parts of acrylonitrile-butadiene-styrene polymer, and 1.2 parts of heat stabilizer 1.2 parts of polyethylene wax and 1.2 parts of stearic acid are placed in a high-speed mixer, and the temperature of the raw materials is raised to 120°C under the action of 950rpm high-speed stirring, and then changed to 475rpm and low-speed stirring. Under the action of cooling water and stirring, the raw materials The temperature is lowered to 80°C, and then the material is discharged at a low speed of 130rpm to complete the premixing of PVC mixture.

[0038] 3) Melt and blend the pre-mixed materials on a double-roller mill at 18...

Embodiment 3

[0040] 1) Dry 40 parts of magnesium hydroxide (5μm), 40 parts of layered double hydroxide (20μm), and 80 parts of magnesium carbonate (30μm) at 110°C for 2 hours to remove moisture; things to use.

[0041] 2) Then mix the above-mentioned heat-suppressing compound with 40 parts of polyvinyl chloride resin, 0.5 part of methacrylic acid-butadiene-styrene polymer, 5.5 parts of acrylate resin, 2.4 parts of heat stabilizer, 0.8 part of stearic acid, Put 0.8 parts of polyethylene wax and 0.8 parts of silicone powder into a high-speed mixer, raise the temperature of the raw materials to 120°C under the action of high-speed stirring at 860rpm, then change to 430rpm and stir at a low speed, and reduce the temperature of the raw materials under the action of cooling water and stirring Lower the temperature to 80°C, and then discharge the material at a low speed of 70rpm to complete the premixing of PVC mixture.

[0042] 3) Mix and extrude the pre-mixed materials in a twin-screw extruder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com