Flame-retardant straw-based panel and manufacturing method thereof

A wood-based panel and straw technology, applied in chemical instruments and methods, manufacturing tools, flat products, etc., can solve the problems of endangering the health of users, imbalance of carbon-nitrogen ratio, and consumption of large wood, etc., and achieve good waterproof and insect-proof, easy to hold Nail force, the effect of improving the internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

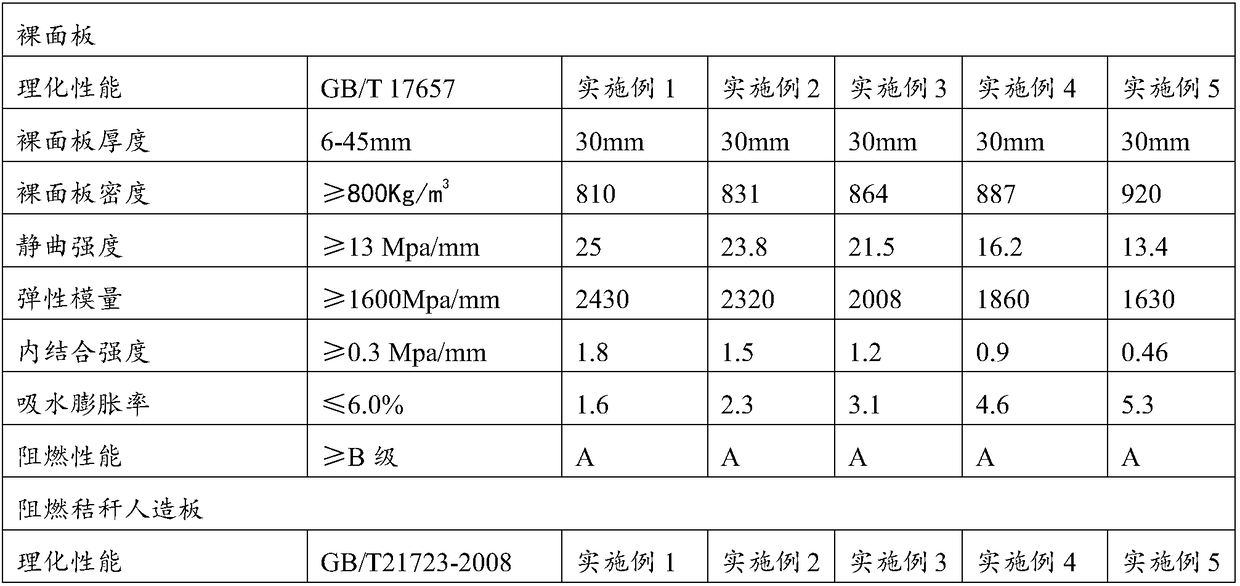

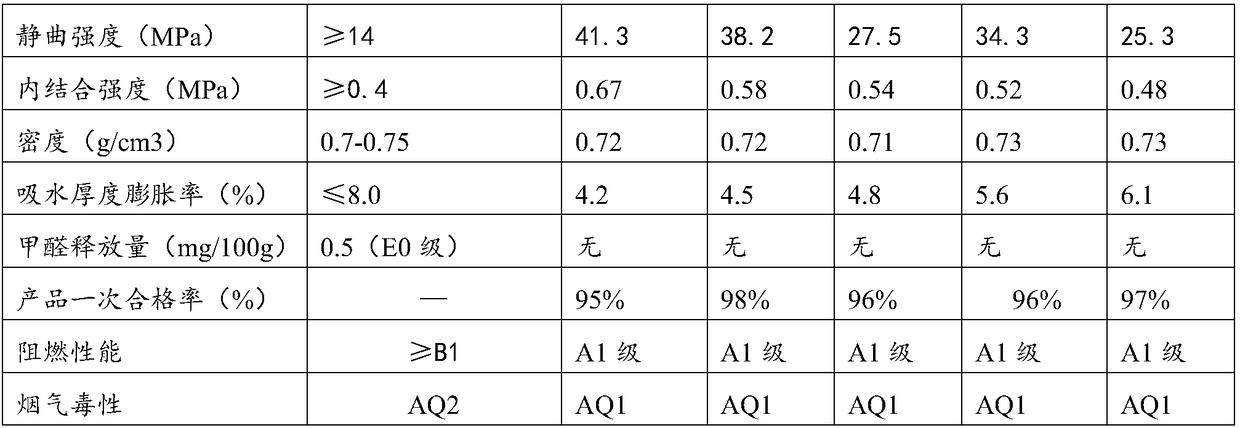

Examples

Embodiment 1

[0068] The raw material composition of the flame retardant straw wood-based panel of this embodiment is as follows:

[0069] 1. Preparation of binder for flame retardant straw wood-based panels:

[0070] Preparation of binder: 1) Add polyvinyl alcohol PVA17-99 and water into the reaction kettle in turn, the mass ratio of polyvinyl alcohol to water is 0.15:1, stir evenly at a speed of 100rpm, heat to 120°C, At a speed of 250rpm, maintain for 3h;

[0071] 2) After the mixed material obtained in step 1) is cooled to room temperature, add ethylene copolymer emulsion VAE718, the mass ratio of the mixed material to ethylene copolymer emulsion is 1:1, the temperature is 45°C, and the stirring speed is 600rpm Under the rotating speed, maintain 2h.

[0072] 3) Add calcium chloride with 10% of the mass of the product obtained in step 2), and stir evenly at room temperature at a stirring speed of 600-800 rpm, and discharge to obtain the binder.

[0073] 2. Preparation of flame-retarda...

Embodiment 2

[0082] The raw material composition of the flame retardant straw wood-based panel of this embodiment is as follows:

[0083] 1. Preparation of binder for flame retardant straw wood-based panels:

[0084] Preparation of binder: 1) Add polyvinyl alcohol PVA17-88 and water into the reaction kettle in sequence, the mass ratio of polyvinyl alcohol to water is 0.45:1, stir evenly at a speed of 150rpm, heat to 120°C, At a speed of 280rpm, maintain for 4h;

[0085] 2) After the mixed material obtained in step 1) is cooled to room temperature, add ethylene copolymer emulsion VAE710, the mass ratio of the mixed material to ethylene copolymer emulsion is 0.95:1, the temperature is 45°C, and the stirring speed is 620rpm Maintain 1.5h under the speed of rotation.

[0086] 3) Add 8% magnesium chloride by mass of the product obtained in step 2), stir evenly at room temperature at a stirring speed of 600 rpm, and discharge to obtain the binder.

[0087] 2. Preparation of flame-retardant st...

Embodiment 3

[0096] The raw material composition of the flame retardant straw wood-based panel of this embodiment is as follows:

[0097] 1. Preparation of binder for flame retardant straw wood-based panels:

[0098] Preparation of binder: 1) Add alkyl phosphoric acid modified polyvinyl alcohol and water into the reaction kettle in sequence, the mass ratio of alkyl phosphoric acid modified polyvinyl alcohol to water is 0.95:1, stir evenly at 150rpm, heat After reaching 150°C, maintain it for 3.5 hours at a rotational speed of 380rpm;

[0099] 2) After the mixed material obtained in step 1) is cooled to room temperature, it is added to ethylene copolymer emulsion VAE716, the mass ratio of the mixed material to ethylene copolymer emulsion VAE716 is 1.25:1, at a temperature of 45°C, the stirring speed is At the speed of 600rpm, keep it for 3h.

[0100] 3) Add magnesium chloride of 5% by mass of the product obtained in step 2), stir evenly at room temperature at a stirring speed of 650 rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com