Pure china-fir three-layer real-wood integrated material and making method

A production method and technology of Glulam, applied in the field of Glulam, can solve the problems of cracking, mildew and rot, affecting product quality and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

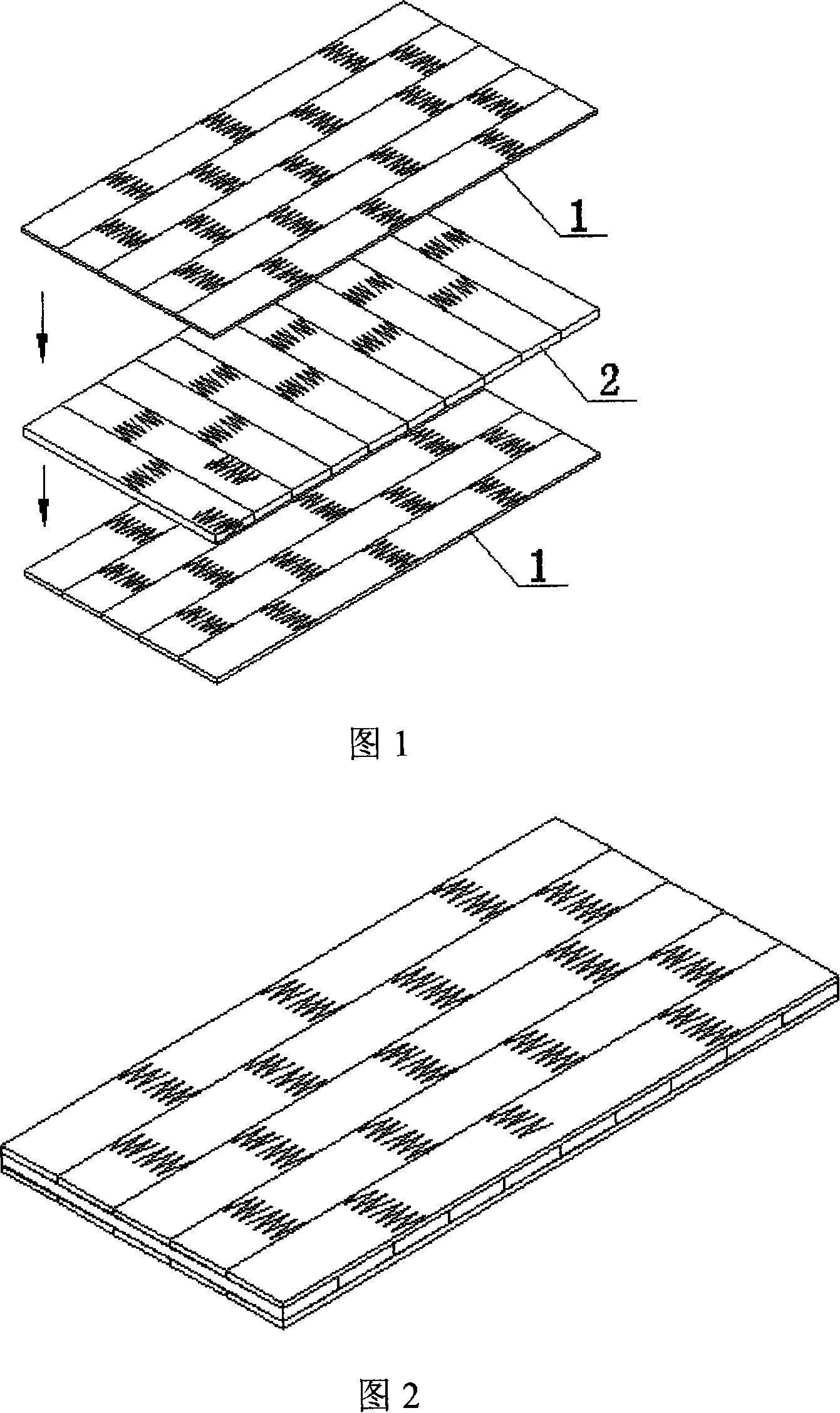

[0007] Below in conjunction with accompanying embodiment the process for making of the present invention is described in detail:

[0008] 1. Panel production: Use fir squares with a size of 4-6cm×5-12cm to plan and determine the thickness through four-sided planing, and finger-join the planed squares to lengthen to about 2480mm through a comb-tooth tenon jointing machine; Cut the finger-joined strips into strips with a thickness of 4 to 4.5mm and a length of 2480mm through a multi-blade saw, and then use a jigsaw mechanism to cut the strips of the same thickness into a panel with a length and width of 2480×1245mm1 .

[0009] 2. Middle board production: use fir squares with a specification of 4-6cm×5-12cm to plan and determine the thickness through four-sided planing, and finger-join the planed squares to lengthen to about 1245mm through a comb-tooth tenon jointing machine; Next, cut the finger-joined strips into strips with a thickness of 9.4mm and a length of 1245mm through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com