Method for manufacturing novel material floor keel by utilizing wastes

A waste and flooring technology, which is applied in the field of manufacturing new material floor keels, can solve the problems of high cost, low strength, load-bearing walls, poor waterproof and fireproof performance, etc., and achieve low cost and good nail holding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

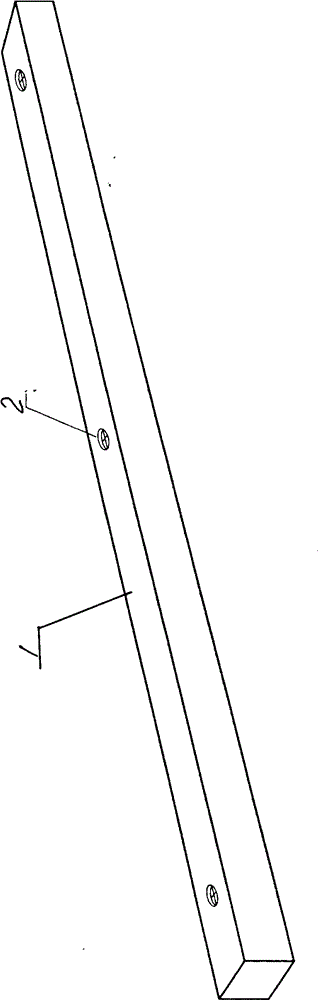

Image

Examples

Embodiment Construction

[0013] Choose 80-200 meshes including attapulgite waste residue 8%, fly ash 10%, straw 3%, slag 7%, paper mill sludge 5%, waste plastic (bag) 7%, perlite 10% as raw materials; 10% of cement, 5% of lime, 2% of talcum powder, and 3% of gypsum powder are used as auxiliary materials; 2% of 50-100mm glass fiber filaments are selected as aggregate; mixed with 28% magnesium chloride liquid material to form a slurry.

[0014] After mixing and soaking for 8 to 24 hours, stir and discharge through the formwork and dry to the profile floor keel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com