Light calcined magnesia calcinator suspension calcination device

A light-burned magnesia and suspension roasting technology, which is applied in lime production and other fields, can solve problems such as slow decomposition reaction speed, low activity in the product, and reverse phase movement, and achieve rapid response, flexible control, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

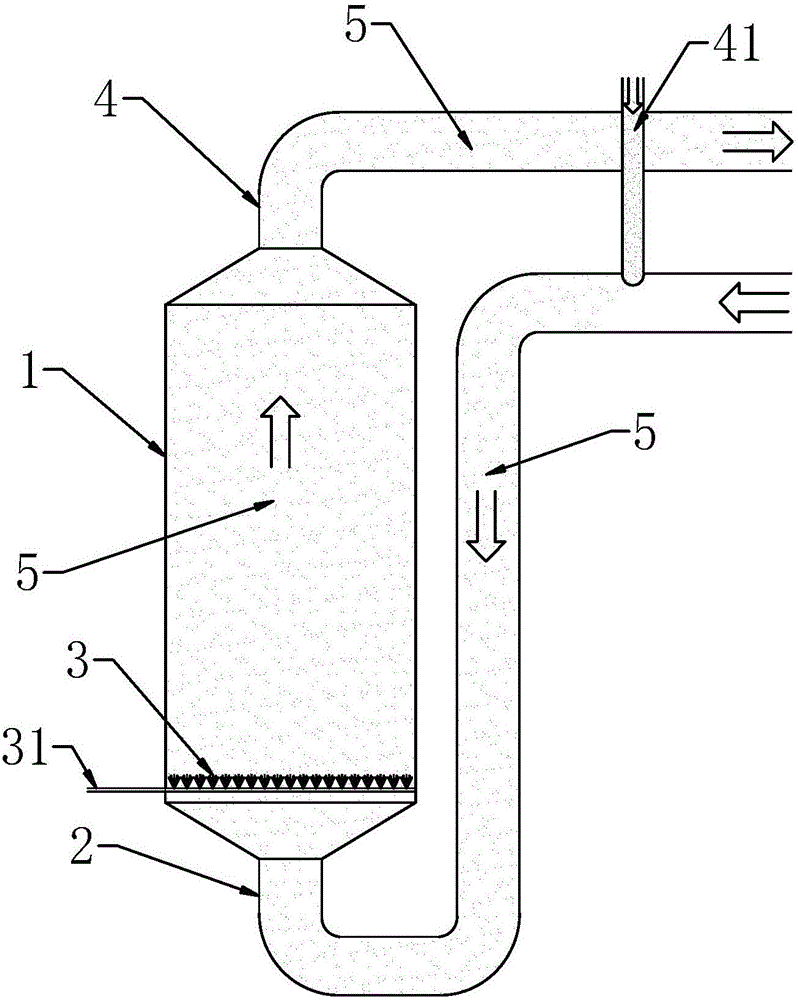

[0011] The light-burned magnesia roasting kiln suspension roasting device of the present invention comprises a kiln body 1, the bottom of the kiln body 1 is provided with a gas material inlet pipe 2, the top of the kiln body 1 is provided with a gas material outlet pipe 4, and the kiln body There is a fuel inlet 31 on the side wall, and the fuel inlet 31 is connected to the fuel nozzle 3 arranged in the kiln body. Before the gas material inlet pipe 2, there is a magnesite powder and an air preheating device 21, and after the gas material outlet pipe 4, there is a gas Material separation device 41.

[0012] The preheated magnesite powder and air enter the kiln from the gas material inlet pipe 2 at the lower part, the magnesite powder is in a suspended state driven by the updraft and rises in the same direction, and fuel such as gas or heavy oil is injected into the kiln from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com