Drum coal mining machine rocker arm comprehensive state parameter online monitoring device

A technology of integrated status and monitoring devices, applied in measuring devices, testing of machine/structural components, measuring heat, etc., can solve problems such as inability to completely remove faults, low start-up rate of coal shearers, etc., to promote balanced production and improve reliability And accuracy, high protection level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

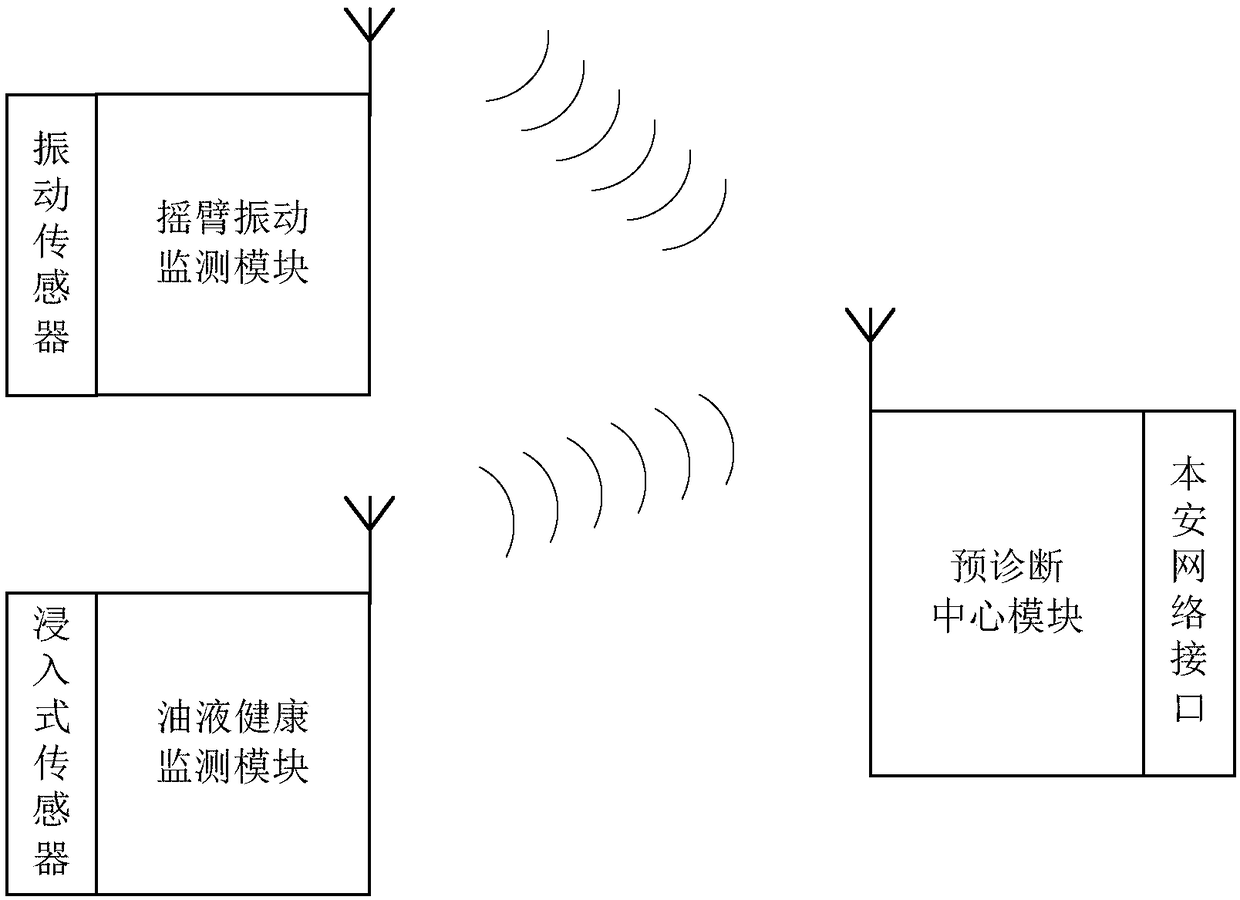

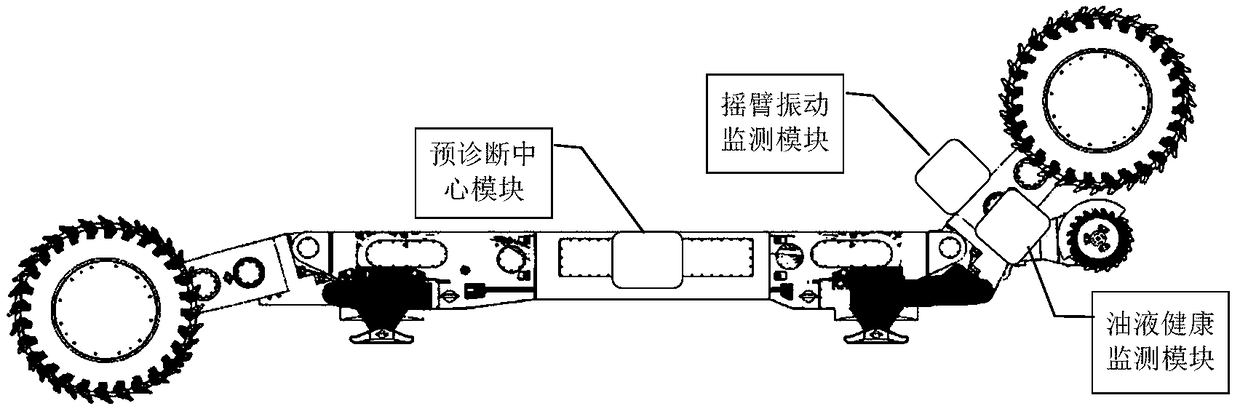

[0022] The invention discloses an online monitoring device for comprehensive state parameters of the rocker arm of a drum shearer, such as figure 1 As shown, it includes the intrinsically safe rocker vibration monitoring module, the intrinsically safe oil health monitoring module and the intrinsically safe pre-diagnosis center module.

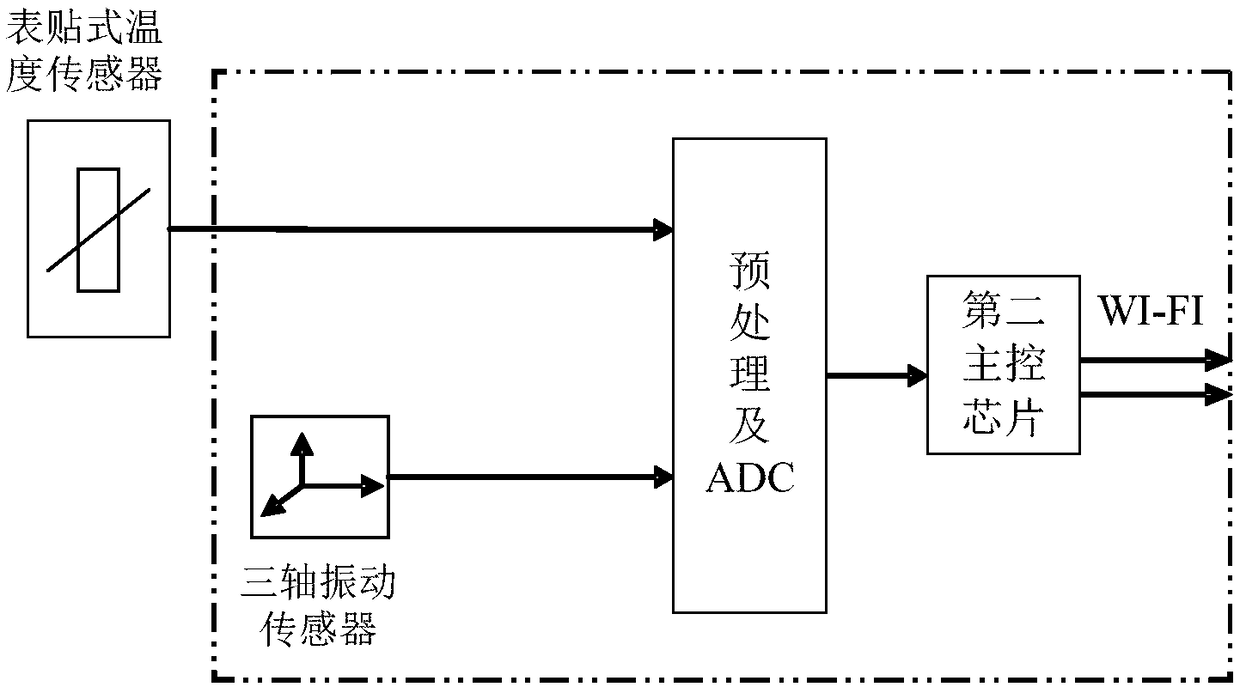

[0023] The rocker arm vibration monitoring module and the oil health monitoring module are respectively used for online monitoring of the rocker arm vibration and the lubricating oil condition of the rocker arm transmission system, and they communicate with the pre-diagnosis center module through wired communication and / or wireless communication respectively. to communicate ( figure 1 In the shown embodiment, the wireless WIFI communication method is adopted), and the collected monitoring data information of the vibration of the rocker arm and the state of the oil is transmitted to the pre-diagnosis center module. The pre-diagnosis center modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com