Efficient lime clarifier for sugar solution and its prepn and use

A production method and clarifier technology, applied in sugar production, sugar juice purification, application, etc., can solve the problems of low effective CaO content, low lime utilization rate, and poor quality of sugar solution, so as to achieve high utilization rate and reduce The effect of evaporative steam consumption and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

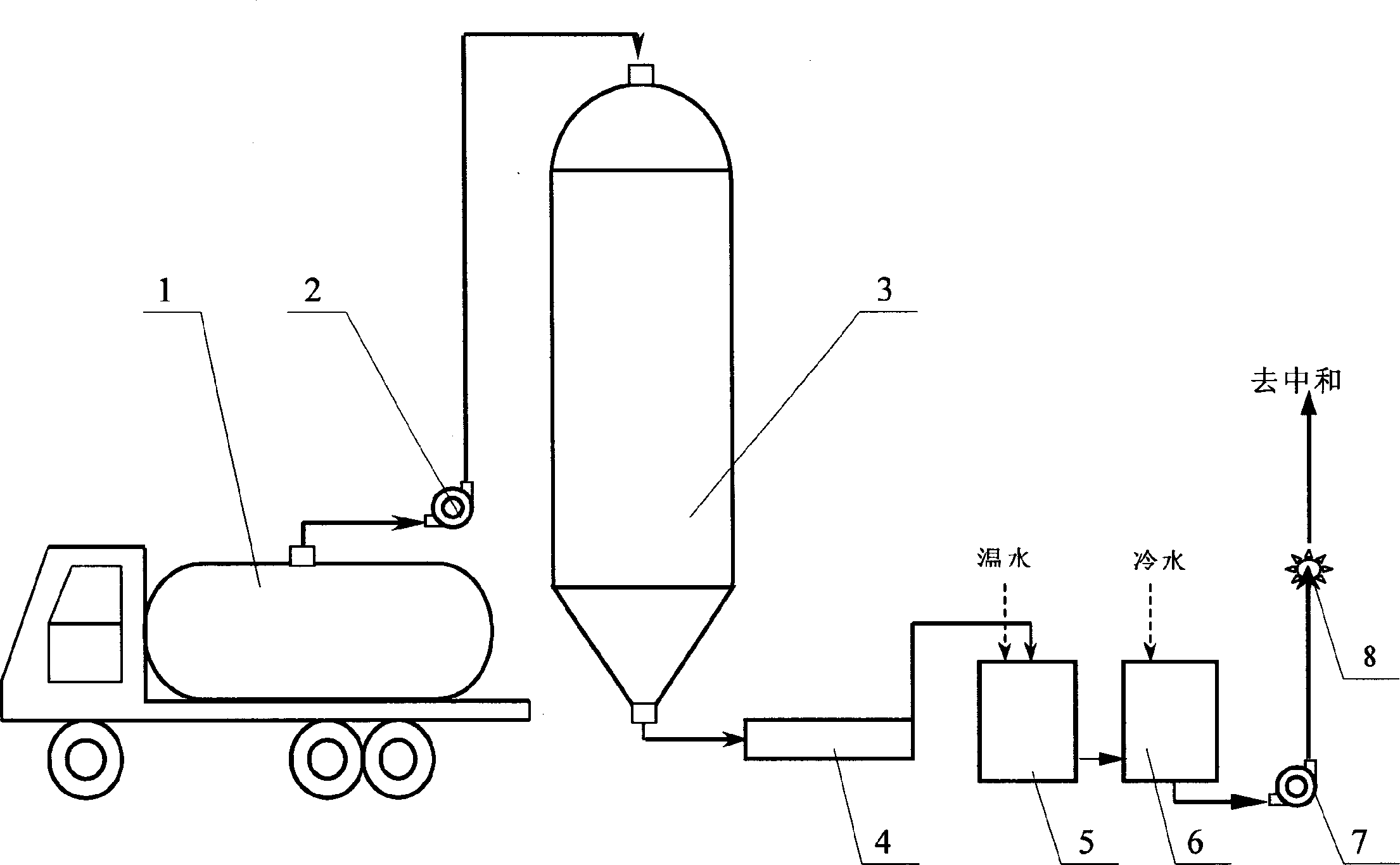

Method used

Image

Examples

Embodiment 1

[0071] A high-efficiency lime clarifier for sugar, the high-efficiency active lime clarifier is a powdery lime compound, the content of each component in the compound is calculated as:

[0072] Effective CaO≥85% MgO≤4.5% SiO 2 ≤2.0%

[0073] Fe 2 o 3 ≤0.3% Al 2 o 3 ≤0.5% CaSO 4 ≤1.0%

[0074] Sucrose≤1×10 -3 % NaCl≤1×10 -3 %

[0075] The physical and chemical indicators are as follows:

[0076] Activity 250~300mL

[0077] Particle size≤125μm

Embodiment 2

[0079] The preparation method of above-mentioned high-efficiency lime clarifying agent for sugar comprises the following steps:

[0080] a, material preparation: take the following component raw materials in proportion for subsequent use, and the content of each component is calculated in parts by weight:

[0081] Limestone-CaCO 3 100 parts by weight

[0082] Industrial salt-NaCl 0.05 parts by weight

[0083] 10 parts by weight of ordinary industrial coal

[0084] b. Calcination:

[0085] Put the raw materials of the above components into a lime kiln and calcinate at 900°C-1250°C for 2-6 hours;

[0086] c. Pulverization: Put the calcined quicklime into a mill and pulverize it so that its particle size is less than 125 μm;

[0087] d. Classification: The pulverized quicklime is classified by a classifier, and the particle size is less than 125 μm, which is the high-efficiency lime clarifier for sugar of the present invention.

[0088] As a transformation of the...

Embodiment 3

[0092] The method for using the high-efficiency lime clarifier for sugar described in claim 1 in clarifying the sugar solution comprises making milk of lime, adding milk of lime, neutralization process, and said making milk of lime comprises the following steps:

[0093] A. The first step of elimination:

[0094] Put the high-efficiency lime clarifier for sugar into the first disinfection tank, add 60°C hot water according to the ratio of high-efficiency lime clarifier for sugar: water=100 parts by weight: 100 parts by weight, and stir evenly;

[0095] B. The second step of cancellation:

[0096]Take out the lime milk from the first disinfection tank, put it into the second disinfection tank, add a certain amount of cold water at 30°C, stir, and dilute the lime milk to 8-20Be;

[0097] As a transformation of the embodiment of the present invention, in the first step of elimination and process, the ratio of high-efficiency lime clarifying agent for sugar and water can also be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com