Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

A technology of nano-zinc oxide and composite emulsion, applied in the field of preparing nano-zinc oxide/acrylate graft type composite emulsion, can solve the problem of high cost, poor stability, low coating efficiency and low grafting rate of nano-composite emulsion, etc. problems, to achieve the effect of improving coating efficiency and grafting rate, overcoming high cost and wide application of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

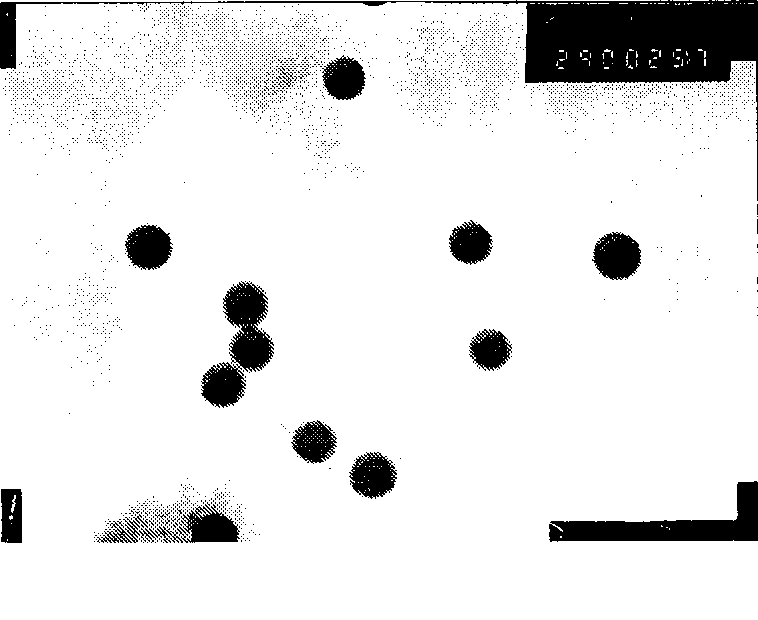

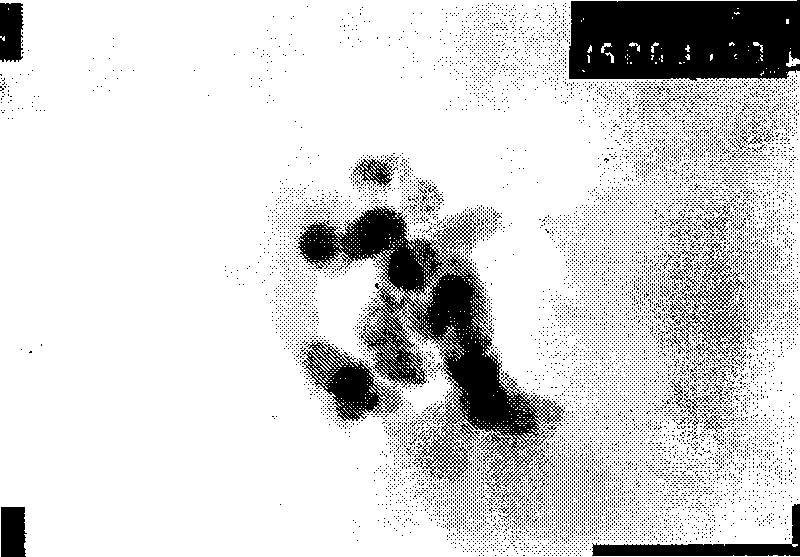

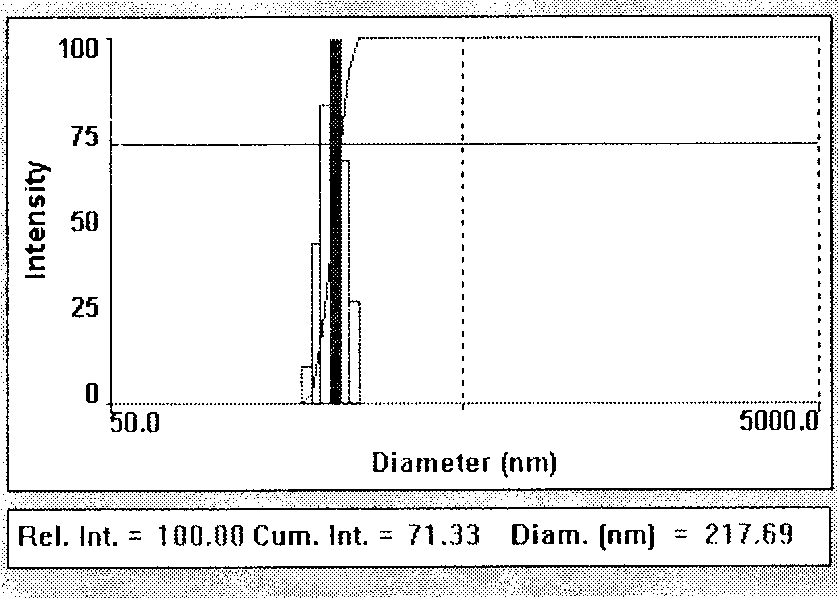

Image

Examples

Embodiment 1

[0019] Deionized water 250 Mixed monomer 100nm Zinc oxide particles 5

[0020] Dimethyl sulfoxide 45 Azobisisovalerate 5 n-Hexadecane 2

[0021] Emulsifier OP-10 2 Emulsifier MS-1 5.

[0022] Wherein: mixed monomer is: methyl methacrylate 60, butyl acrylate 38, methacrylic acid 2.

[0023] Specific steps:

[0024] 1) Ultrasonic disperse 5 parts of dry nano zinc oxide particles in dimethyl sulfoxide for 10 minutes, then add 5 parts of azobisisovaleric acid, stir and react for 3-8 hours, after high-speed centrifugation, wash with ethanol 3-5 times, vacuum drying to obtain nano-ZnO particles anchored on the surface of the azo initiator;

[0025] 2) Dissolve emulsifiers OP-10 and MS-1 in 250 parts of water to form an aqueous phase solution;

[0026] 3) Add 2 parts of n-octadecane to 100 parts of acrylate mixed monomer, then add the nano-ZnO particles anchoring the azo initiator obtained in step 1), and ultrasonically vibrate for 20 minutes to form an oil phase pre-dispersion ...

Embodiment 2

[0029] Sodium dodecylbenzenesulfonate replaces MS-1, octadecane replaces hexadecane, and the mixed monomers are: methyl methacrylate 50, ethyl acrylate 48, acrylic acid 2.

[0030] Specific steps:

[0031] 1) Ultrasonic disperse 5 parts of dry nano zinc oxide particles in dimethyl sulfoxide for 10 minutes, then add 5 parts of azobisisovaleric acid, stir and react for 3-8 hours, after high-speed centrifugation, wash with ethanol 3-5 times, vacuum drying to obtain nano-ZnO particles anchored on the surface of the azo initiator;

[0032] 2) Dissolving emulsifier OP-10 and sodium dodecylbenzenesulfonate into 250 parts of water to form an aqueous solution;

[0033] 3) Add 2 parts of n-octadecane to 100 parts of mixed monomers, then add the nano-ZnO particles anchoring the azo initiator obtained in step 1), and ultrasonically vibrate for 20 minutes to form an oil phase pre-dispersion;

[0034] 4) Add the oil phase pre-dispersion liquid obtained in step 3) into the water phase solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com