Epoxy phenolic resin adhesive and epoxy phenolic adhesive tape and laminated board manufactured by adhesive

A technology of epoxy phenolic resin and phenolic resin, applied in the field of epoxy phenolic resin adhesive, epoxy phenolic adhesive tape and laminate, which can solve the problems affecting the mechanical and electrical properties of products, short storage period of adhesive tape, low cross-linking density, etc. problems, to achieve the effect of eliminating the production process of thermosetting phenolic resin, convenient source of raw materials, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

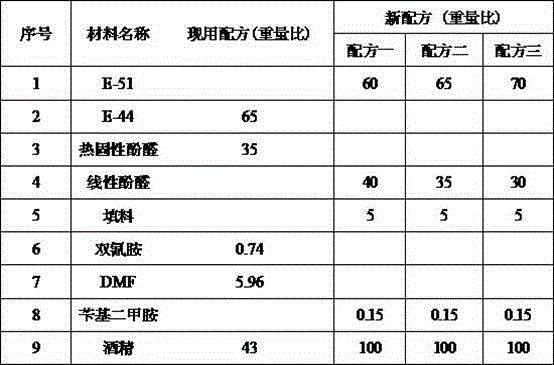

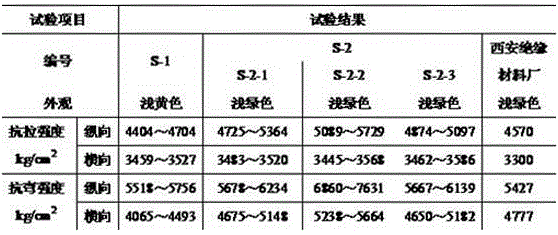

[0065] 1 Epoxy phenolic resin adhesive formula

[0066] Table 1 Adhesive formula

[0067]

[0068] 2 Preparation of epoxy phenolic glue

[0069] According to the resin ratio in Table 1, proceed as follows:

[0070] (1) Stir the phenolic resin and E-51 with a mixer at a temperature of 80~90℃;

[0071] (2) Dilute the filler with alcohol and mix it evenly with a mixer;

[0072] (3) Mix (1) and (2), and stir evenly with a mixer;

[0073] (4) Add dicyandiamide and benzyl dimethylamine, and stir evenly with a mixer.

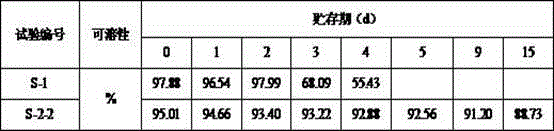

[0074] 3 Preparation of epoxy phenolic tape

[0075] After coating with EW140 alkali-free glass cloth, bake it at 110℃ for 3~5min. Tape index: the glue content is 35-40%; the solubility is above 90%.

[0076] 4 Preparation of epoxy phenolic laminate

[0077] The pressing of epoxy phenolic tape is carried out on a 100-ton press with a surface of 250×250mm 2 . The pressing process is shown in Table 2.

[0078] Table 2 Pressing process

[0079] crafting process Temperature / ℃P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com