Tip-end type needle-free electrostatic spinning equipment

An electrospinning, needle-free technology, applied in textile and papermaking, filament/thread forming, fiber processing, etc., to achieve the effect of improving product yield and output, improving product yield and quality, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

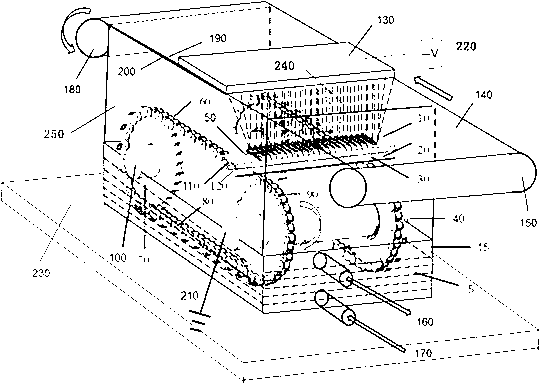

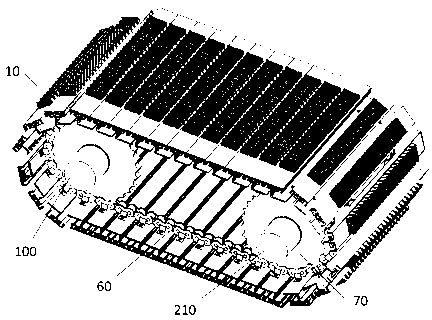

[0040] The metal card clothing with a specification of 5606×56109 produced by Baisha Card Clothing Factory in Guangshan County, Henan Province was used as the electrospinning unit.

[0041]There are 34 pairs of connecting pieces and 34 needle boards evenly distributed along the outer surface of each chain, the length of the needle boards (ie product width) is 30cm, the width of the needle boards is 3.4cm, and the nearest horizontal gap between two adjacent needle boards is 0.2cm.

[0042] The width of the L-shaped connecting pieces is 0.2 cm, and the distance between two adjacent L-shaped connecting pieces is 0.6 cm.

[0043] The outer diameter of the sprocket is 11.6 cm, the center distance of the sprocket is 25 cm, the length of the chain is 65 cm, and the speed of the sprocket is 10 rev / min.

[0044] The base fabric is unwound and wound at a speed of 10 m / min. The negative electrode voltage is -50kV, and the receiving distance (that is, the distance between the base fabri...

Embodiment 2

[0047] The metal card clothing with a specification of 5715×4210 produced by Baisha Card Clothing Factory in Guangshan County, Henan Province was used as the electrospinning unit.

[0048] There are 34 pairs of connecting pieces and 34 needle boards evenly distributed along the outer surface of each chain, the length of the needle boards (ie product width) is 30cm, the width of the needle boards is 3.4cm, and the nearest horizontal gap between two adjacent needle boards is 0.2cm.

[0049] The width of the L-shaped connecting pieces is 0.2 cm, and the distance between two adjacent L-shaped connecting pieces is 0.6 cm.

[0050] The outer diameter of the sprocket is 11.6 cm, the center distance of the sprocket is 25 cm, the length of the chain is 65 cm, and the speed of the sprocket is 10 rev / min.

[0051] The base fabric is unwound and wound at a speed of 10 m / min. The negative electrode voltage is -48kV, and the receiving distance is 15cm.

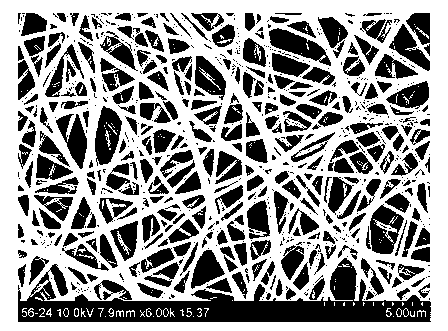

[0052] The weight of the PVA nano...

Embodiment 3

[0054] The metal card clothing with a specification of 8808×7220 produced by Baisha Card Clothing Factory in Guangshan County, Henan Province was used as the electrospinning unit.

[0055] There are 34 pairs of connecting pieces and 17 needle boards evenly distributed along the outer surface of each chain, the length of the needle board (ie product width) is 30cm, and the width of the needle board is 3.4cm.

[0056] The width of the L-shaped connecting pieces is 0.2 cm, and the distance between two adjacent L-shaped connecting pieces is 0.6 cm.

[0057] The outer diameter of the sprocket is 11.6 cm, the center distance of the sprocket is 25 cm, the length of the chain is 65 cm, and the speed of the sprocket is 10 rev / min.

[0058] The base fabric is unwound and wound at a speed of 10 m / min. The negative electrode voltage is -30kV, and the receiving distance is 15cm.

[0059] The weight of the PVA nanofiber film product finally produced by this equipment is 1g / m 2 , the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com