Dough kneading device, dough kneading method and noodle making machine

A noodle bin and dough technology, which is applied in the field of machinery and noodle, can solve the problems of rapid water absorption of flour, insignificant kneading effect, single mixing method, etc., achieve good promotion value, suitable gluten expansion, and improve dough quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

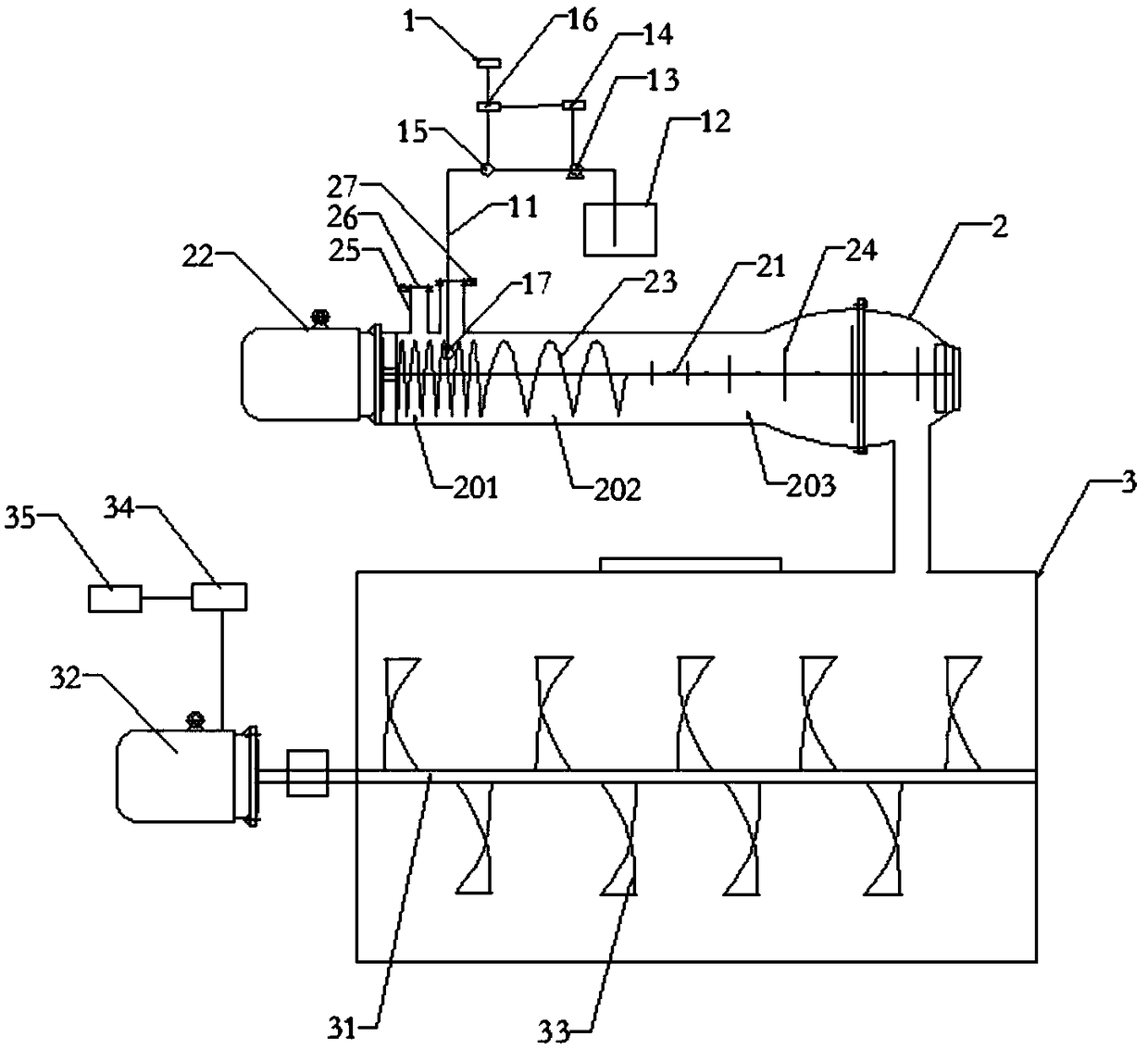

[0090] like figure 1 As shown, this embodiment provides a dough mixing device, including a water supply mechanism 1, a first-level dough mixing bin 2 and a second-level dough mixing bin 3 communicated with the first-level dough mixing bin 2;

[0091] The first stirring shaft 21 is arranged in the first-stage mixing shaft 2, and one end of the first stirring shaft 21 stretches out from the first-stage mixing shaft 2 and is connected with the first power mechanism 22 that drives the first stirring shaft 21 to rotate; The inner part of the noodle bin 2 is set as three inter-connected stirring zones, which are the first stirring zone 201, the second stirring zone 202 and the third stirring zone 203 in sequence;

[0092] Wherein, a helical paddle 23 is installed on the first stirring shaft 21 in the first stirring area 201 and the second stirring area 202, and the pitch of the paddle 23 on the first stirring shaft 21 in the first stirring area 201 is less than The pitch of the pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com