Diamond thin-film reinforcement on tantalum spinning head surface by chemical gas phase deposition

A technology of diamond film and surface chemistry, which is applied in the direction of spinneret assembly, gaseous chemical plating, metal material coating process, etc., to achieve the effect of improving spinnability, ensuring precision and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

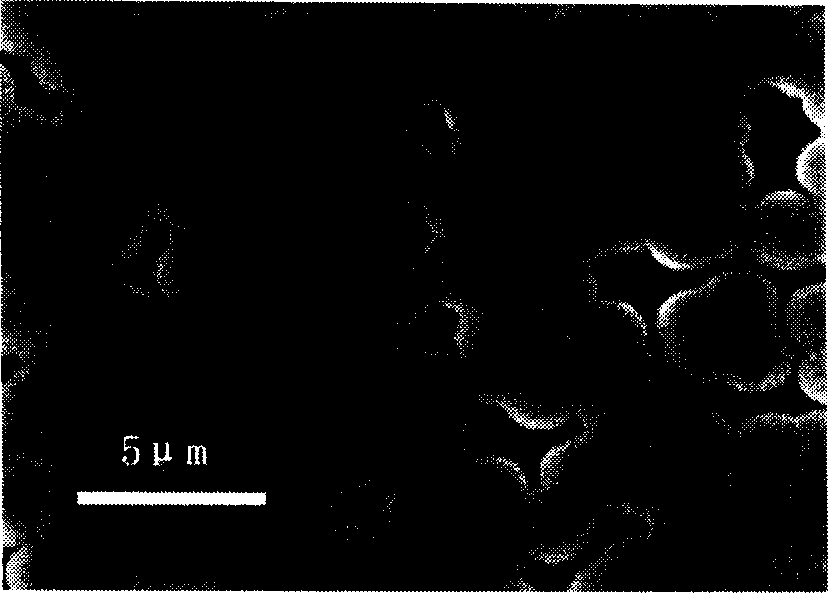

[0033] The pretreated tantalum spinneret with a surface roughness of 0.1μm is first carbonized, the carbon source concentration is 12%, the air pressure is 4kpa, the substrate temperature is 960°C, and the carbonization time is 0.5h, and then placed in the CVD chamber. Carry out the diamond film deposition, the carbon source concentration is 1.5%, the air pressure is 4kpa, the substrate temperature is 600°C, the deposition time is 0.5h, and it is taken out after cooling.

[0034] The deposited diamond film ( figure 1 ) The thickness is 3μm, which is not dense enough, the surface roughness of the spinneret is 0.7μm, and the surface hardness is 1100HV. After the spinnability test, the spinning quality is good. After long-term use, the spinneret has no obvious deformation, the surface is slightly corroded, and the diamond film does not fall off.

Embodiment 2

[0036] The pretreated tantalum spinneret with a surface roughness of 0.1μm is directly placed in a CVD chamber without carbonization pretreatment for diamond film deposition. The carbon source concentration is 1.5%, the air pressure is 4kpa, and the substrate temperature is 600°C. The deposition time is 0.5h, and it is taken out after cooling.

[0037] The thickness of the deposited diamond film is 3μm, which is not dense enough, the surface roughness of the spinneret is 0.7μm, and the surface hardness is 1100HV. After spinnability test, the spinning quality is good. After long-term use, the spinneret has no obvious deformation, the surface is slightly corroded, and the diamond film is partially peeled off.

Embodiment 3

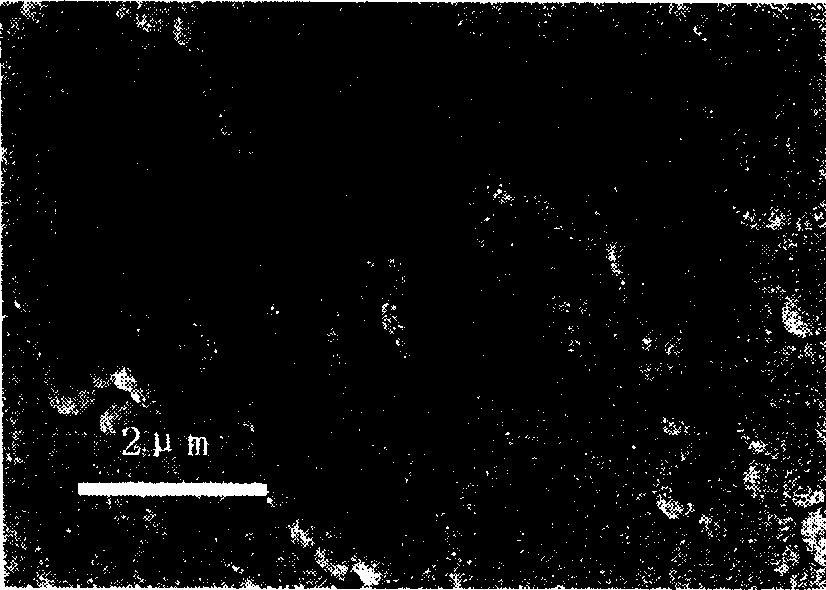

[0039] The pretreated tantalum spinneret with a surface roughness of 0.1μm is first carbonized, the carbon source concentration is 12%, the air pressure is 4kpa, the substrate temperature is 960°C, and the carbonization time is 0.5h, and then placed in the CVD chamber. Carry out diamond film deposition, carbon source concentration 3%, pressure 1.5kpa, substrate temperature 750°C, deposition time 0.6h, and take it out after cooling.

[0040] The deposited diamond film ( figure 2 ) The particles have become smaller, with a thickness of 3μm, which is relatively dense, the surface roughness of the spinneret is 0.4μm, and the surface hardness is 1150HV. After the spinnability test, the spinning quality is good. After long-term use, the spinneret has no obvious deformation, the surface is not corroded, and the diamond film does not fall off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com