Intelligent management system for intelligent spinning workshop

An intelligent management system and intelligent spinning technology, applied in the field of spinning, can solve problems such as restricting the production efficiency of enterprises, difficult to maintain product quality, and difficult to find cotton blending solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

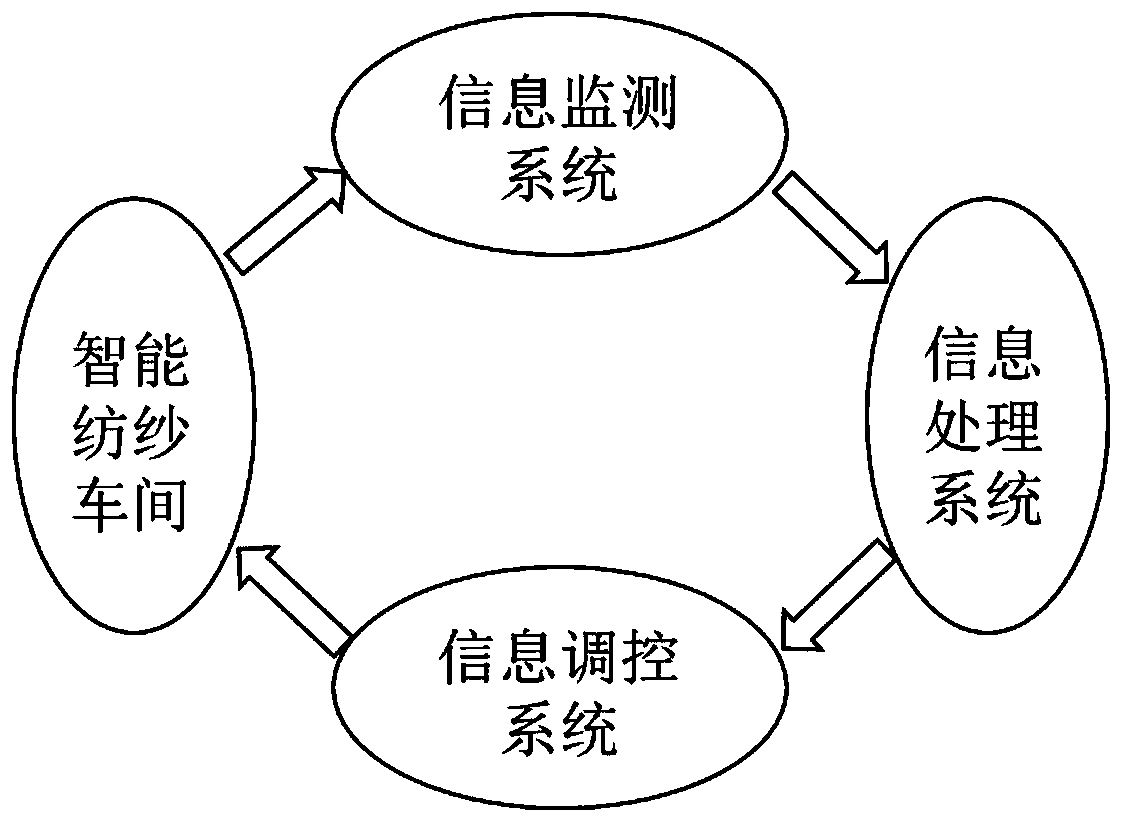

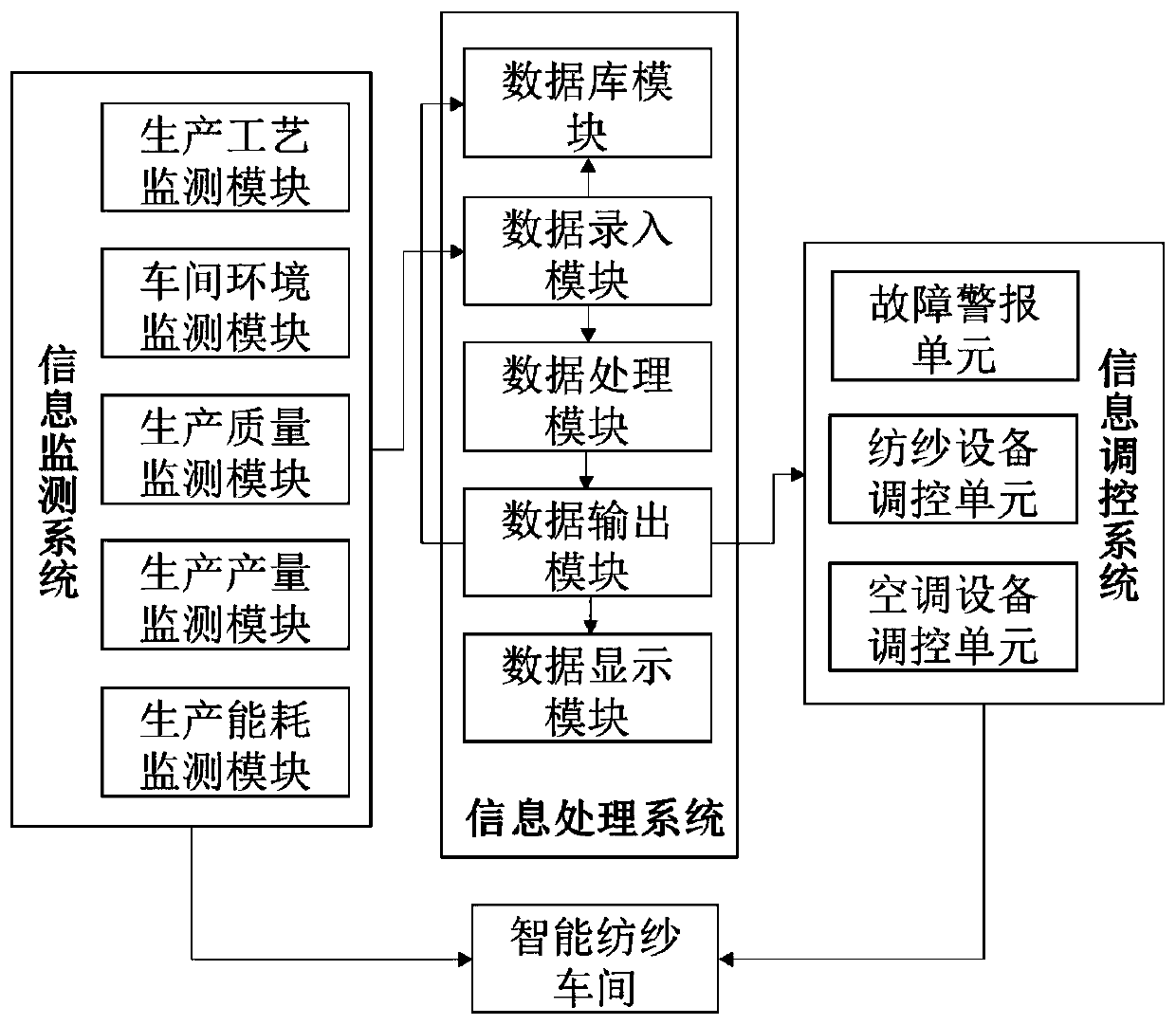

[0110] see figure 1 and figure 2 As shown, based on the above-mentioned spinning principle, the intelligent management system of the intelligent spinning workshop provided by the present invention includes:

[0111] Information monitoring system, used to monitor the data in the intelligent spinning workshop;

[0112] The information processing system is used to process the data in the intelligent spinning workshop monitored by the information monitoring system to obtain the control parameters of the intelligent spinning workshop; and,

[0113] An information regulation system, used to regulate and control the operation of equipment in the intelligent spinning workshop according to the regulation parameters of the spinning workshop;

[0114] The control parameters of the spinning workshop include control parameters of spinning equipment and control parameters of air conditioning equipment;

[0115] The information control system includes:

[0116] a spinning device control...

Embodiment 2

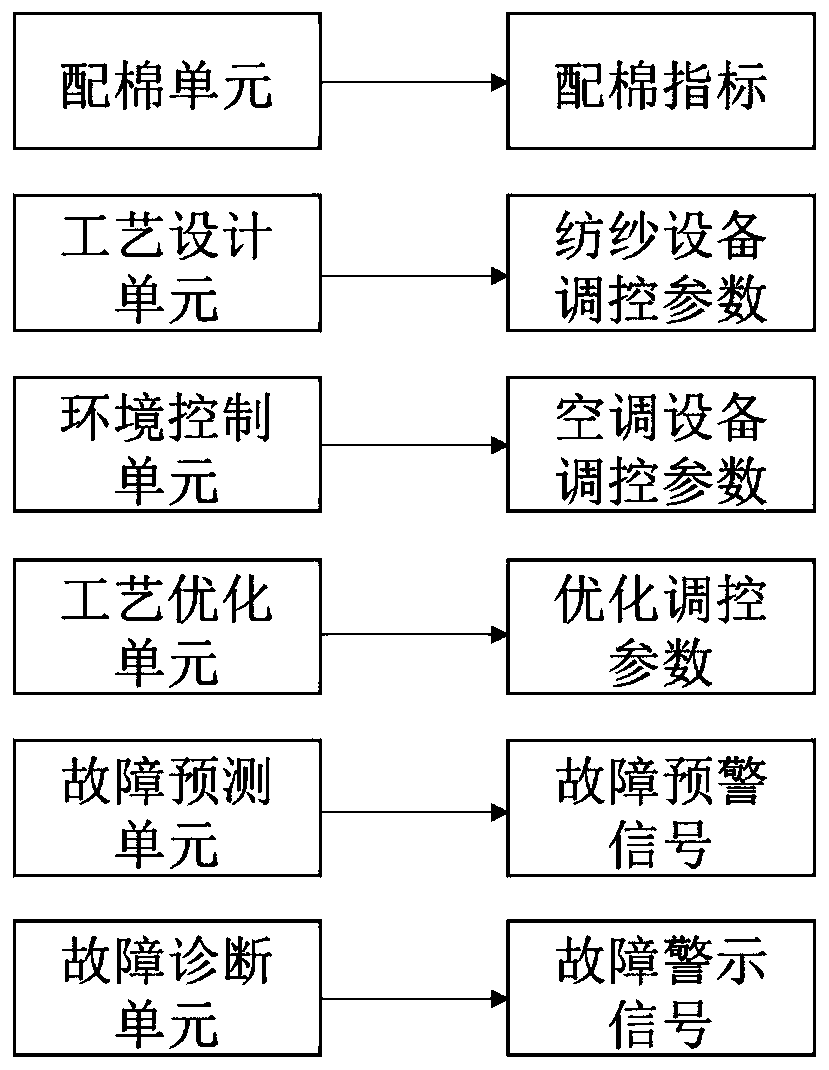

[0230] see figure 2 As shown, compared with Embodiment 1, the intelligent management system of the intelligent spinning workshop provided by Embodiment 2 is different in that the data processing module of the information processing system also includes a fault prediction unit, and the information control system also includes a fault prediction unit. alarm unit;

[0231] The failure prediction unit predicts the failure of the equipment according to the operating status data of the equipment, and sends out a failure warning signal in advance through the failure alarm unit, and proactively shuts down the equipment for maintenance by means of early warning.

[0232] Further, the data processing module of the information processing system further includes a fault diagnosis unit, which is used to judge whether the device is faulty according to the operation status data of the device; and send a fault warning signal through the fault alarm unit.

[0233] Further, the database modul...

Embodiment 3

[0242] Compared with Embodiment 2, Embodiment 3 differs in that the operation monitoring subunit of the cotton opening and cleaning equipment includes a machine vision detection mechanism, and the others are basically the same as Embodiment 1, and will not be repeated here.

[0243] Cotton grasping is the first process in the cotton opening and cleaning process. Its main function is to grasp and open the raw cotton and fibers. The uniformity of the cotton block should be as high as possible. Therefore, the operation monitoring subunit of the cotton opening and cleaning equipment recognizes and extracts the image features of the topographic image of the cotton bale, the topographic image of the plucking machine, and the topographic image of the environment within the working range of catching cotton through the machine vision detection mechanism, and analyzes all The above image features are processed to obtain corresponding processing signals, so as to realize accurate recogni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com