Method and apparatus for making core-spun yarn of steple-fibre covered filament

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing methods and devices of core-spun composite yarns, can solve the problems of low filament coverage, uneven yarn evenness, uneven fabric surface, etc. Improve spinning efficiency and product quality, reduce filament breakage rate, and good process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

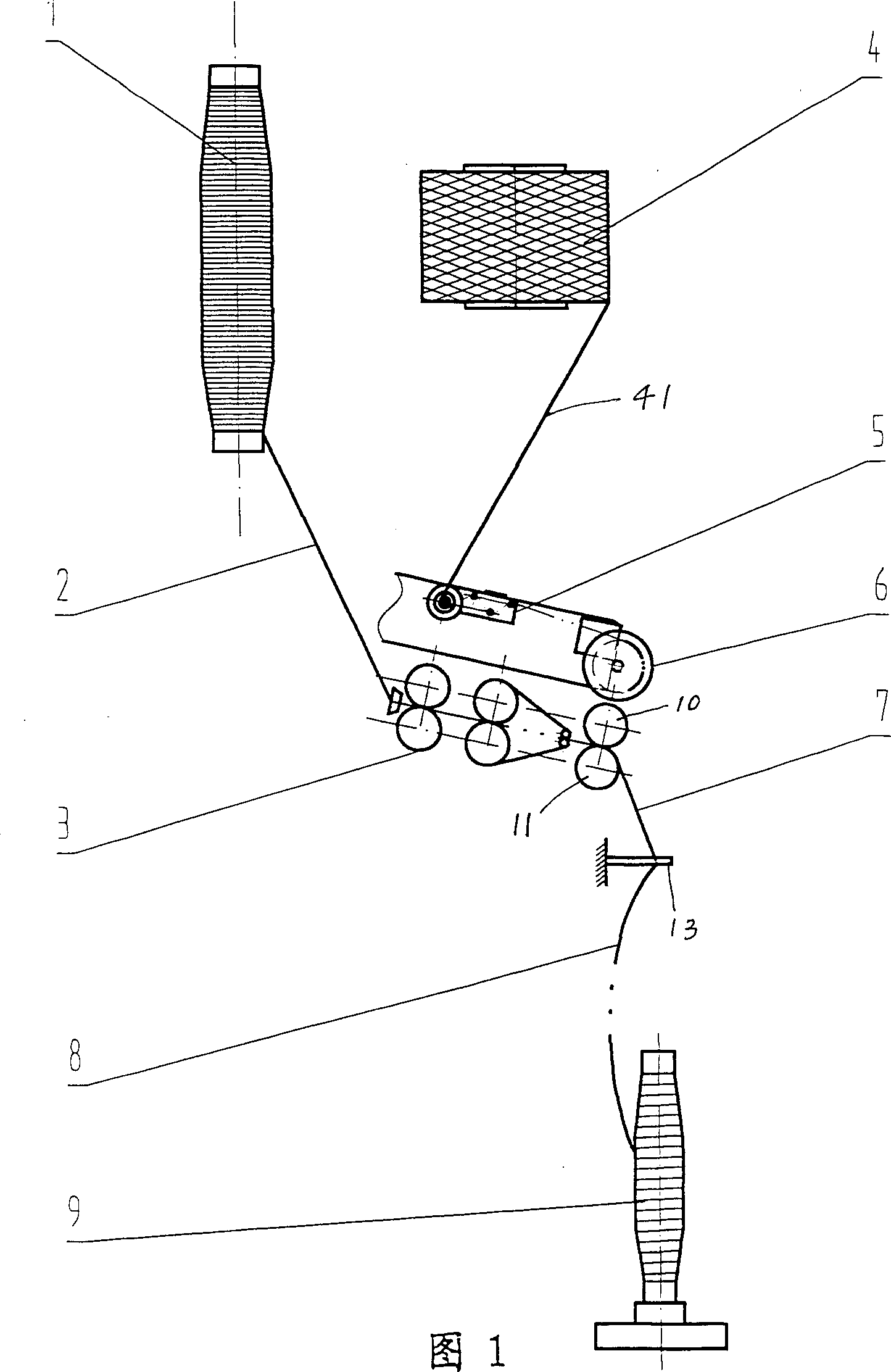

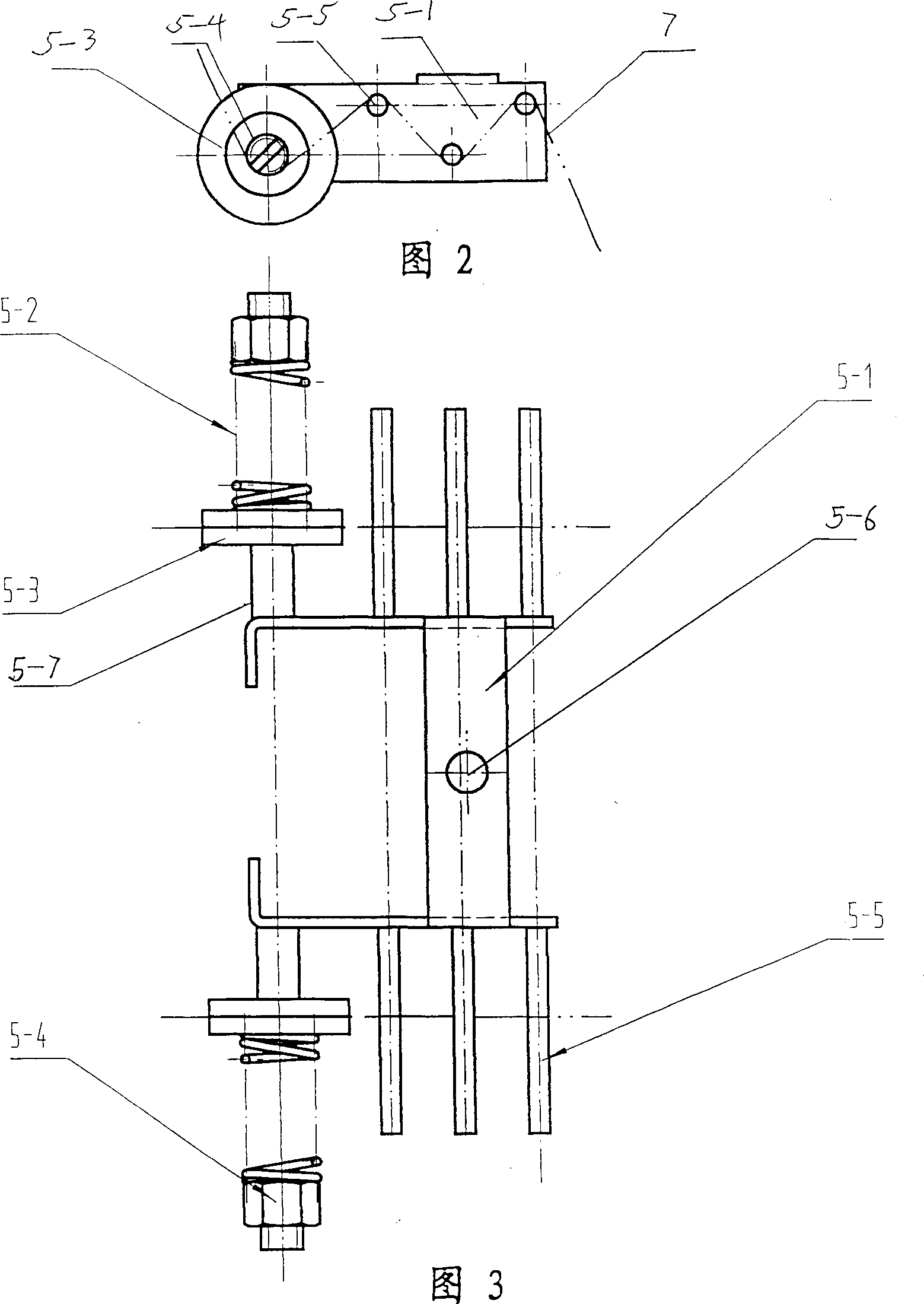

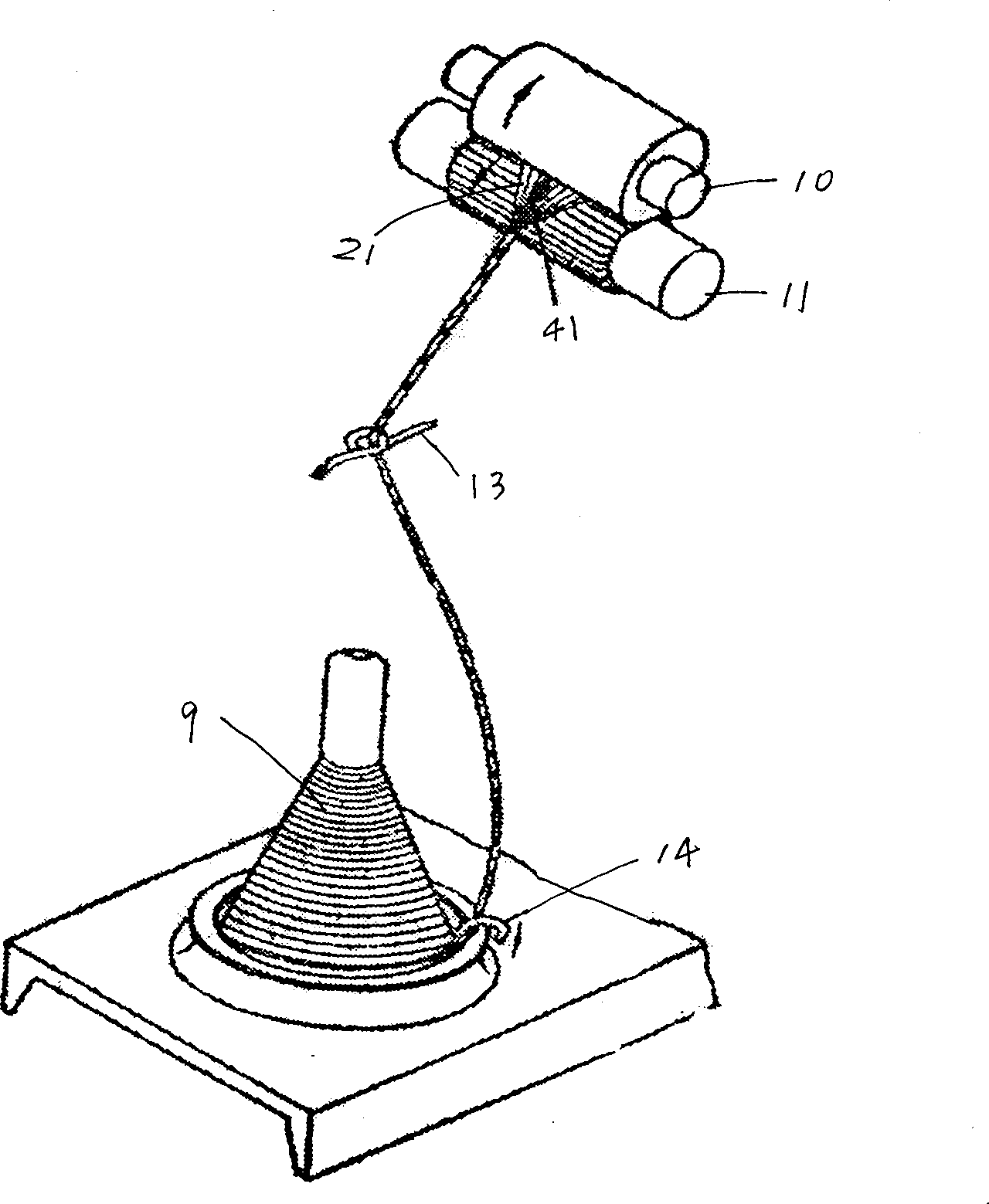

[0047] See Figure 1- Image 6 As shown, the manufacturing method of the core-spun composite yarn of the staple fiber covering the filament of the present invention is to control the tension of the filament 41 from the filament bobbin 4 by the filament tension control device 5, and control the tension of the filament by the guide wheel 6. 41 feeds the position of the staple fiber twisting triangular area, and merges with the staple fiber roving sliver 2 from the staple fiber bobbin 1 to ensure that the filament 41 and the staple fiber roving sliver 2 are twisted all the time when they are compounded and twisted At the center of the triangular area, the composite yarn passes through the composite yarn twisting zone 7 and the balloon 8 to form a core-spun composite yarn in which short fibers are covered with filaments and is wound on the spinning spindle 9, as shown in FIG. 1 .

[0048] The concrete feature of manufacturing method of the present invention is:

[0049] ①In the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com