Traversing compact spinning apparatus

A technology of compact spinning and traverse, which is applied to spinning machines, textiles, papermaking, drafting equipment, etc. It can solve problems such as low strength, excessive hairiness, and deterioration of evenness and details.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

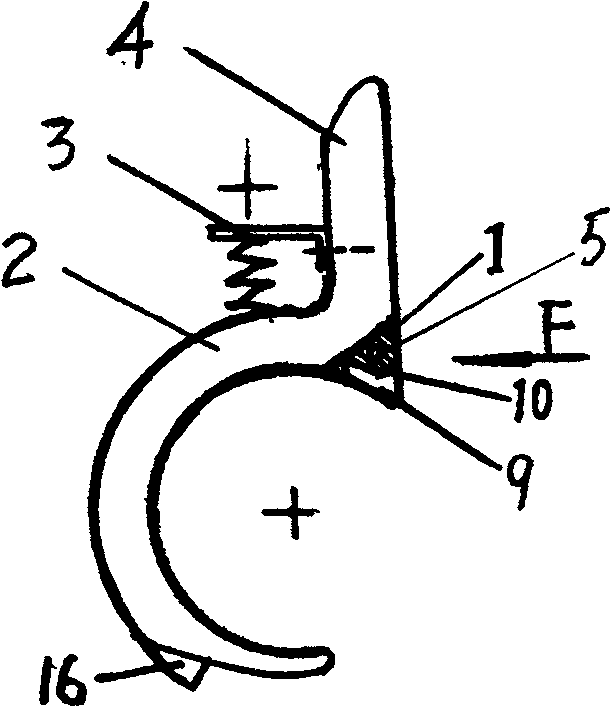

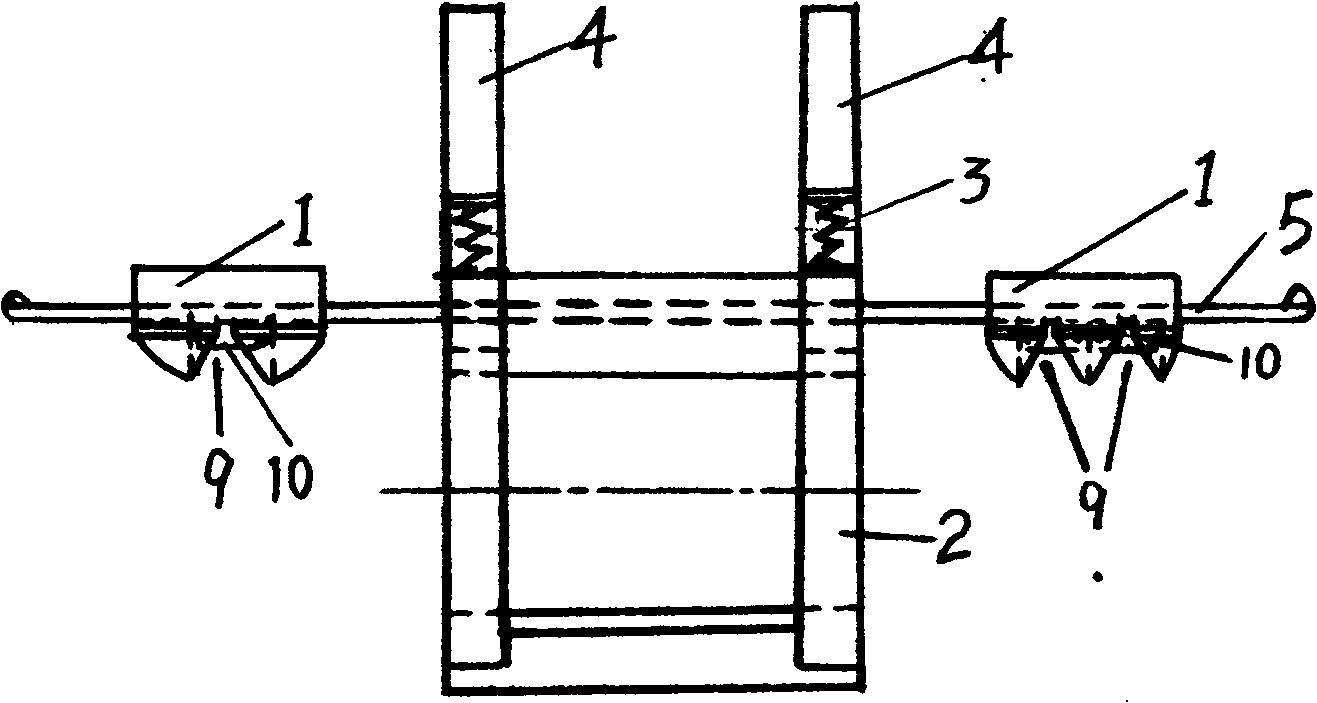

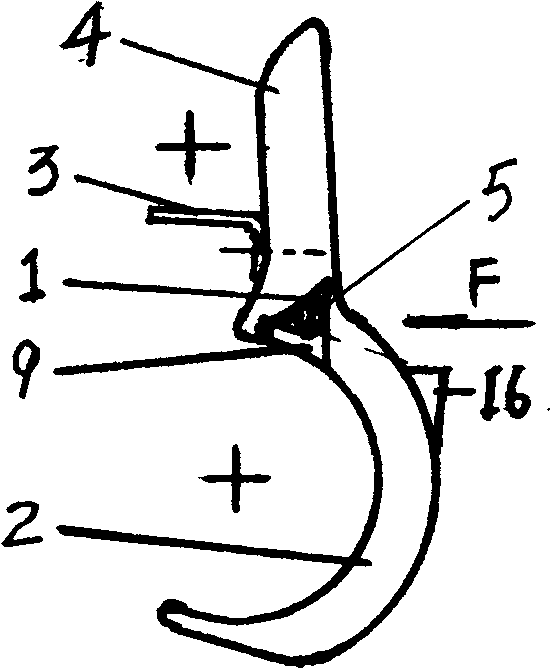

[0034] Fig. 1 Fig. 2 Fig. 3 Fig. 4 shows the traverse type compact spinning device is composed of a compactor 1, a positioner 2, a pressure spring 3, a limit rod 4, a sliding rod 5, etc., among which Figure 1A-G means that the sides of the two vertical sides of the locator are in the shape of a "C", which contains a multi-semicircle whose inner radius is the same as the outer diameter of the front roller without groove and exceeds 180 degrees. Using the elasticity of the material, it can be moved from front to back or from the back Insert the surface of the front roller forward to make the two tightly combined. At the position of the floating area where the positioner 2 passes or the position of the twisting triangle area where the positioner 2 passes, a slender sliding rod 5 is installed in the horizontal direction. The sliding rod 5 The cross-sectional shape of the compactor hole 11 is the same as that of the compactor hole 11 and there is a gap. The compactor is mounted on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com