Electrostatic spinning method for preparing directional nanofiber

A nanofiber and electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of low spinning and collection efficiency, and improve spinning efficiency and spinning quality, fiber Good orientation and adjustable length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

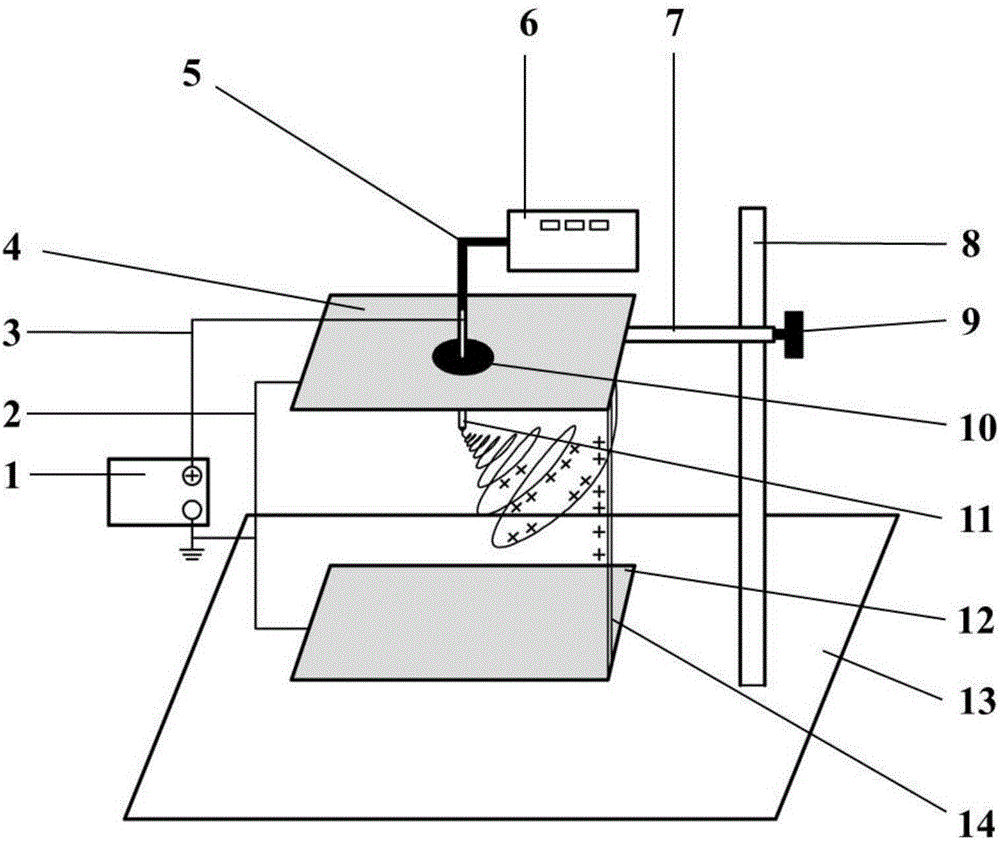

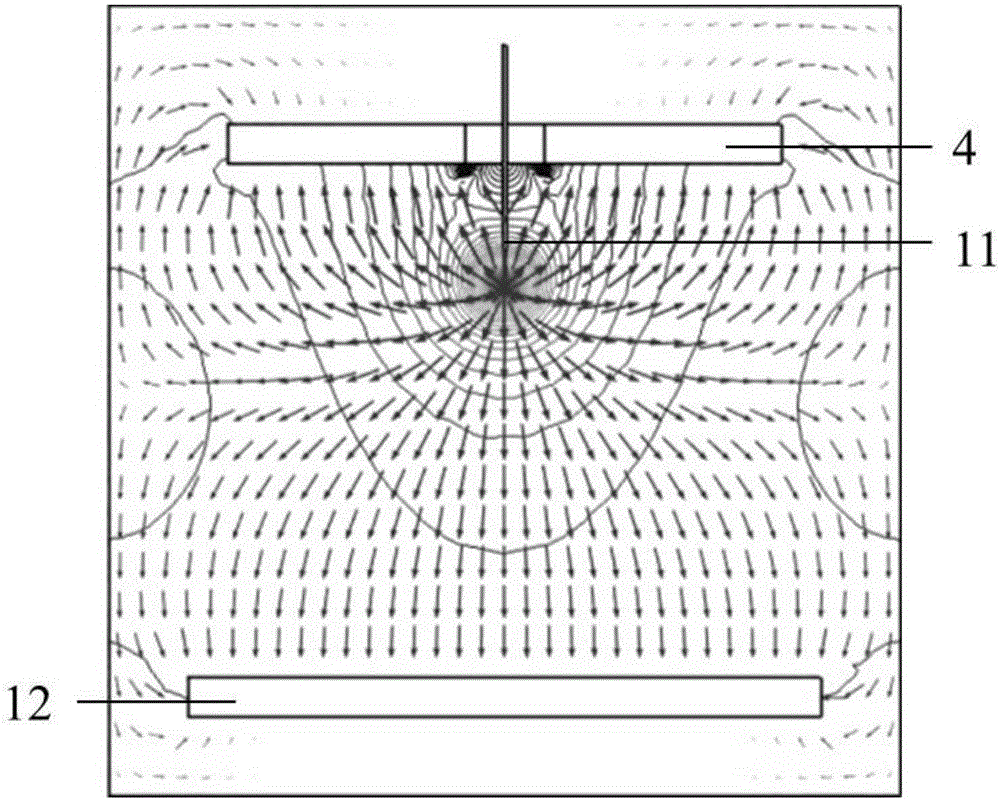

[0018] figure 1 It is a schematic diagram of an electrospinning device for preparing oriented fibers in the present invention. As shown in the figure, the method first installs an electrospinning device, and the specific steps of the method are as follows:

[0019] The first step, install the electrospinning device

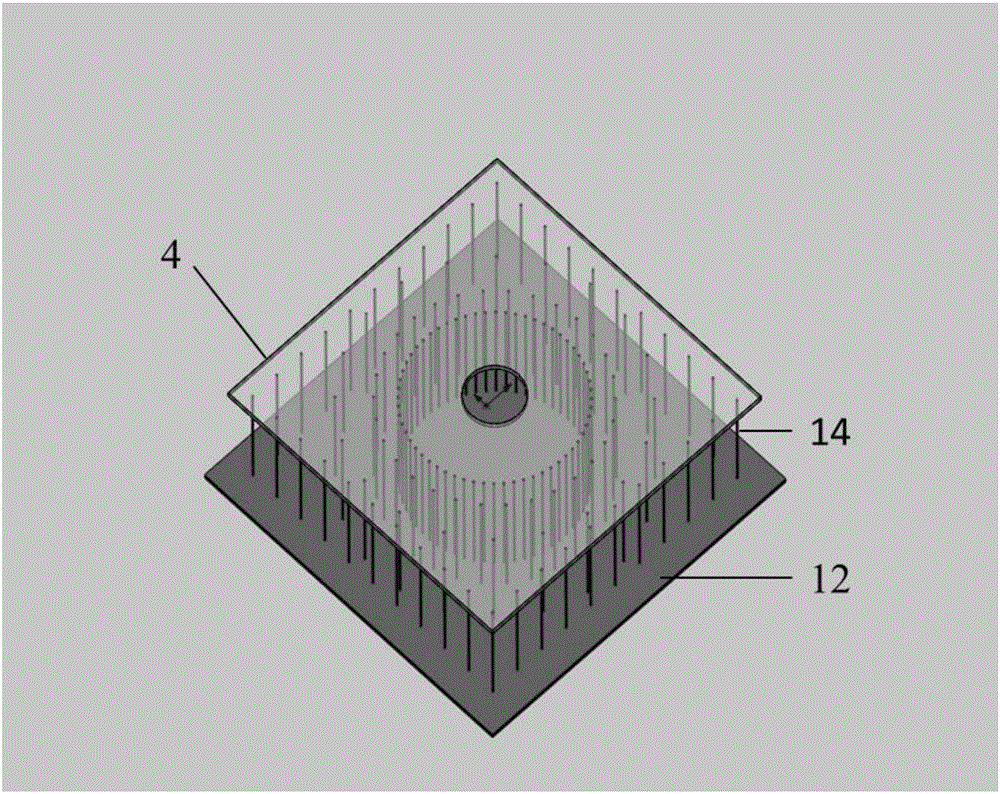

[0020] First, the fixed receiving plate 12 is fixed on the insulating base plate 13, and then the auxiliary plate 4 is connected with the column 8 through the bracket 7, the column 8 is vertically fixed on the insulating base plate 13, and the bracket 7 moves up and down along the axis of the column 8 to Adjust the distance between the auxiliary pole plate 4 and the fixed receiving plate 12, the lower surface of the auxiliary pole plate 4 is parallel to the upper surface of the fixed receiving plate 12; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com