High-speed centrifugal spinning device for producing nanofiber yarn in one-step shaping and production method of nanofiber yarn

A technology of nanofibers and high-speed centrifugation, applied in the textile field, can solve the problems of limited application range of nanofibers, poor mechanical properties of nanofiber membranes, single product form, etc., achieve good industrial production prospects, improve spinning quality, and process repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

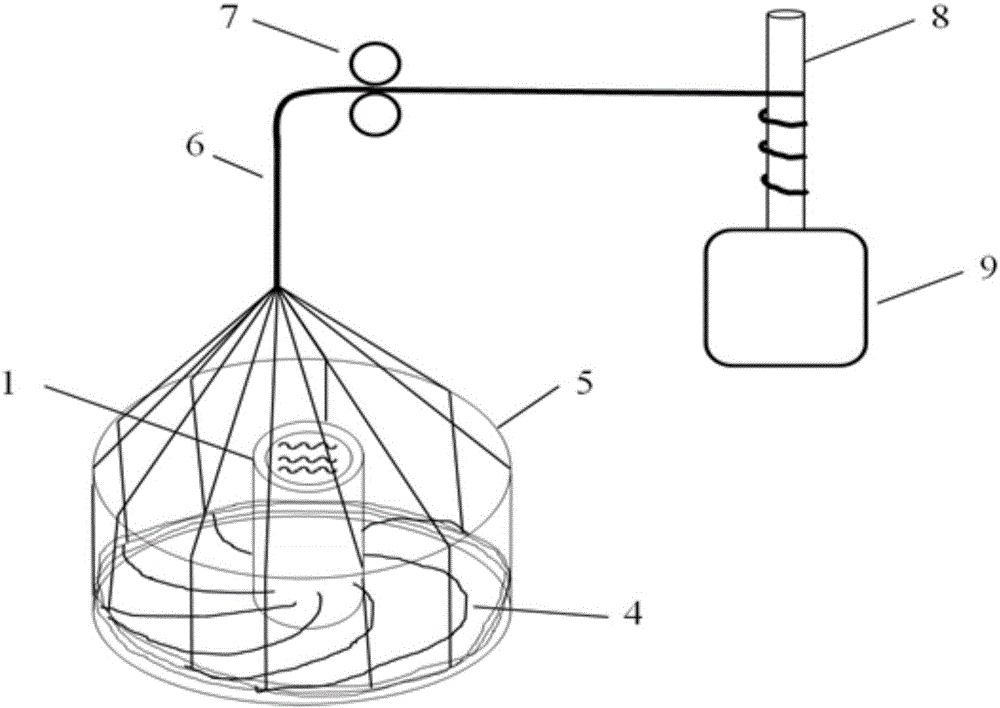

[0031] Embodiment 1: the preparation of PLA nanofiber yarn

[0032] a, the preparation of PLA mass fraction is 5% CHCl 3 The solution was fully dissolved after magnetic stirring and ultrasonication.

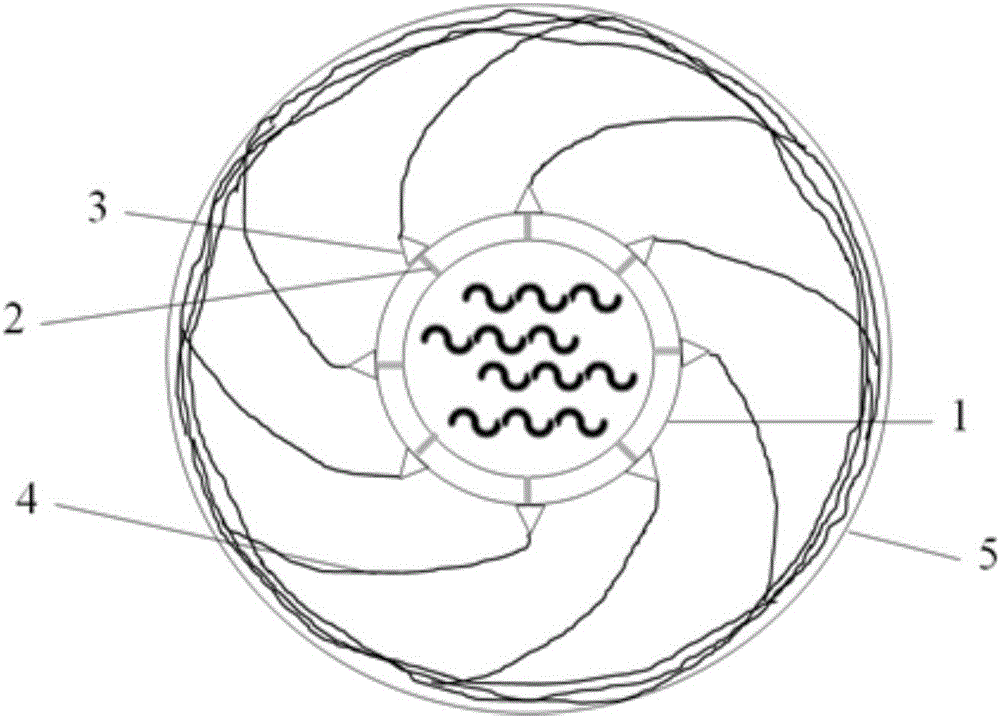

[0033] b, the CHCl that will be obtained 3 The solution is injected into the rotating centrifugal column 1, and the rotating centrifugal column 1, the radial channel 2, and the nozzle 3 are a linkage device, and rotate with the rotating centrifugal column 1 at a high speed, and the radial channel 2 supplies liquid to multiple nozzles 3 continuously.

[0034] c. Under the action of high-speed rotating centrifugal force, CHCl 3 The solution is sprayed out of nozzle 3, during which CHCl 3 The solvent is volatilized, and a plurality of PLA nanofibers 4 are obtained and rotated onto a cylindrical collector 5 . The diameter of the nanofiber can be regulated by controlling the rotational speed of the rotating spin column 1 .

[0035] d, a plurality of single PLA nanofibers 4 on the...

Embodiment 2

[0037] Embodiment 2: the preparation of nylon nanofiber yarn

[0038] a. Prepare a formic acid solution with a nylon mass fraction of 8-12%, and fully dissolve it after magnetic stirring and ultrasonication.

[0039] b. Inject the obtained formic acid solution into the rotating centrifugal column 1, the rotating centrifugal column 1, the radial channel 2, and the nozzle 3 are linkage devices, and rotate at a high speed with the rotating centrifugal column 1, and the radial channel 2 continuously supplies liquid to multiple nozzles 3 .

[0040] c. Under the action of high-speed rotating centrifugal force, the formic acid solution is sprayed out of the nozzle 3, and the formic acid solvent is volatilized during this process, and a plurality of nylon nanofibers are obtained and rotated to the cylindrical collector 5. The diameter of the nanofiber can be regulated by controlling the rotational speed of the rotating spin column 1 .

[0041] d. A plurality of single nylon nanofibe...

Embodiment 3

[0043] Embodiment 3: Preparation of PAN nanofiber yarn

[0044] a. Prepare a DMF solution with a mass fraction of PAN of 5-10%, and fully dissolve it after magnetic stirring and ultrasonication.

[0045]b. Inject the obtained DMF solution into the rotating centrifugal column 1, the rotating centrifugal column 1, the radial channel 2, and the nozzle 3 are linkage devices, and rotate with the rotating centrifugal column 1 at a high speed, and the radial channel 2 continuously supplies liquid to multiple nozzles 3 .

[0046] c. Under the action of high-speed rotating centrifugal force, the DMF solution is sprayed out of the nozzle 3. During this process, the DMF solvent is volatilized, and multiple PAN nanofibers are obtained and rotated to the cylindrical collector 5. The diameter of the nanofiber can be regulated by controlling the rotational speed of the rotating spin column 1 .

[0047] d, a plurality of single PAN nanofibers on the rotating spin column 1 are rotated at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com