Method for preparing polyvinyl alcohol BiVO4 composite fiber by electrostatic spinning method

An electrospinning, polyvinyl alcohol technology, applied in spinning solution preparation, fiber processing, filament/thread forming, etc., can solve the problems of complex preparation process, large powder particle size, long reaction period, etc. The preparation method is simple, the cost is low, and the reaction time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

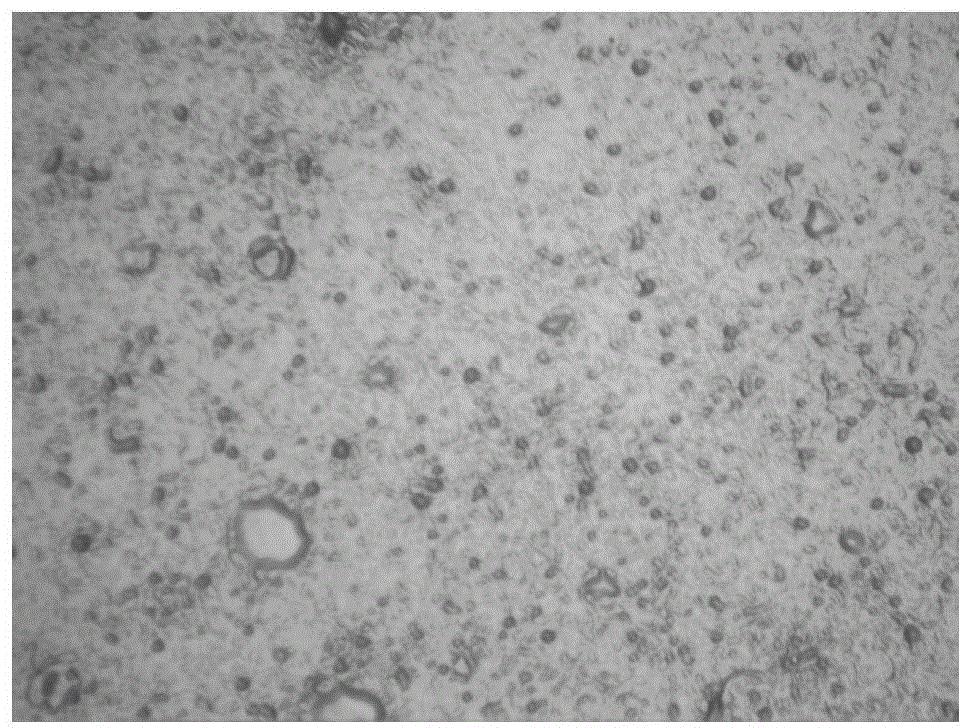

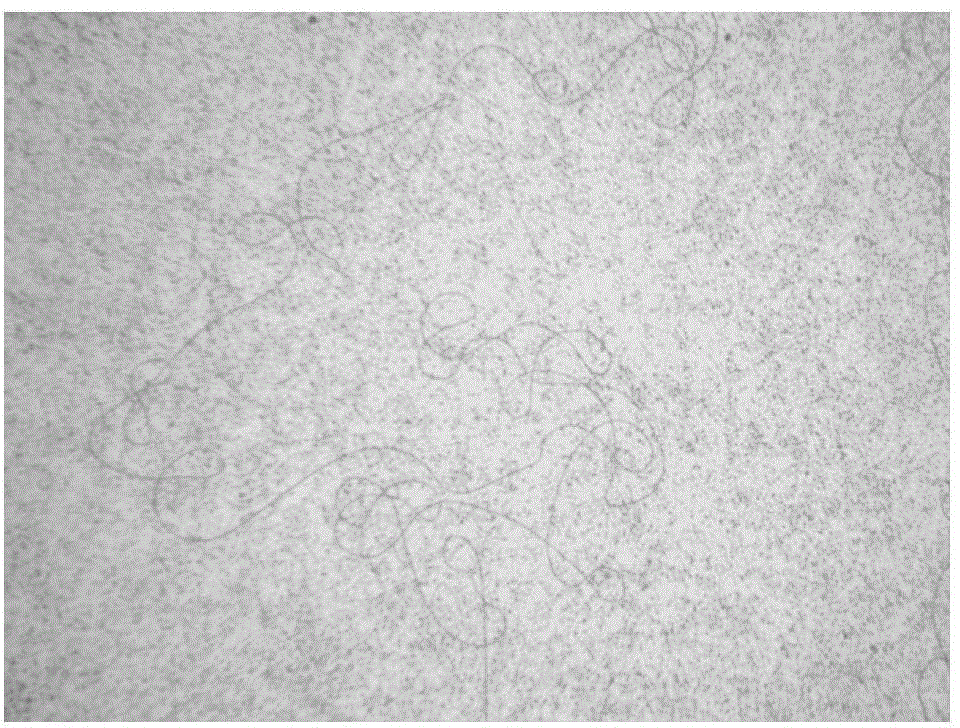

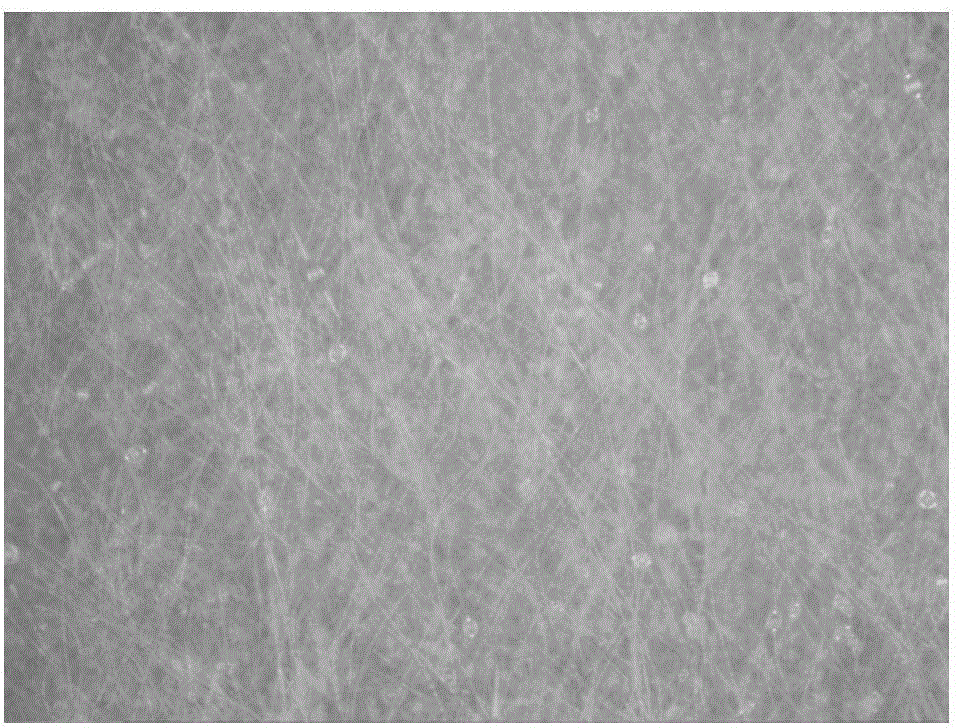

Image

Examples

Embodiment 1

[0029] 1) Preparation of BiVO 4 Precursor solution:

[0030] 1.1) Mix 0.010mol of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and 0.015mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water, place on a magnetic stirrer and stir evenly, then add 3.75mL of ethanolamine (C 2 h 7 NO) and continue to stir until clear to obtain A solution;

[0031] 1.2) Mix 0.010mol of ammonium metavanadate (NH 4 VO 3 ) and 0.015mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water to obtain an orange-yellow mixed liquid; then stir at a constant temperature at 70°C for 30 minutes to make the color of the mixed liquid change to dark blue without precipitation, and obtain B solution;

[0032] 1.3) Mix solution A and solution B according to the molar ratio of n(Bi):n(V)=1:1, and stir for 30 minutes to obtain BiVO 4 Precursor solution;

[0033] 2) Preparation of electrospinning solution:

[0034] According to the volume ratio of...

Embodiment 2

[0038] 1) Preparation of BiVO 4 Precursor solution:

[0039] 1.1) Mix 0.010mol of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H2 O) and 0.015mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water, place on a magnetic stirrer and stir evenly, then add 3.75mL of ethanolamine (C 2 h 7 NO) and continue to stir until clear to obtain A solution;

[0040] 1.2) Mix 0.012mol of ammonium metavanadate (NH 4 VO 3 ) and 0.018mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water to obtain an orange-yellow mixed liquid; then stir at a constant temperature at 70°C for 30 minutes to make the color of the mixed liquid change to dark blue without precipitation, and obtain B solution;

[0041] 1.3) Mix solution A and solution B according to the molar ratio of n(Bi):n(V)=1:1.2, and stir for 30 minutes to obtain BiVO 4 Precursor solution;

[0042] 2) Preparation of electrospinning solution:

[0043] According to the volume ratio of...

Embodiment 3

[0047] 1) Preparation of BiVO 4 Precursor solution:

[0048] 1.1) Mix 0.012mol of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and 0.018mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water, place on a magnetic stirrer and stir evenly, then add 4.5mL of ethanolamine (C 2 h 7 NO) and continue to stir until clear to obtain A solution;

[0049] 1.2) Mix 0.012mol of ammonium metavanadate (NH 4 VO 3 ) and 0.018mol of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) Add 10mL of deionized water to obtain an orange-yellow mixed liquid; then stir at a constant temperature at 70°C for 30 minutes to make the color of the mixed liquid change to dark blue without precipitation, and obtain B solution;

[0050] 1.3) Mix solution A and solution B according to the molar ratio of n(Bi):n(V)=1:1, and stir for 30 minutes to obtain BiVO 4 Precursor solution;

[0051] 2) Preparation of electrospinning solution:

[0052] According to the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com