A kind of preparation method of composite micro-nano fiber film for biological dressing

A technology of micro-nano fibers and biological dressings, which is applied in fiber processing, spinning solution preparation, medical science, etc., can solve the problems of electrospinning difficulties, fast degradation speed, and cytotoxicity, so as to avoid secondary biological toxicity and reduce Toxicity and cost, effectiveness of antimicrobial wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

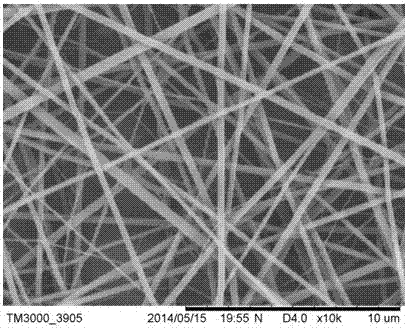

Embodiment 1

[0035] Weigh 0.21g of spongy type I collagen and 0.09g of polyethylene oxide powder (commercially available) and dissolve in 10mL of a mixed solution of hexafluoroisopropanol and acetic acid with a volume ratio of 5:5, and place it on a magnetic stirrer at room temperature to stir completely. Prepare a collagen / polyethylene oxide blend solution with a mass concentration of 3g / mL; weigh 0.27g of chitosan powder and 0.03g of polyethylene oxide powder and dissolve them together in 10mL of 90% acetic acid aqueous solution, and place at room temperature Stir on a magnetic stirrer to make it transparent, and prepare a chitosan / polyoxyethylene blend solution with a mass concentration of 3g / mL.

[0036] Mix the collagen / polyoxyethylene blended solution with a mass concentration of 3g / mL and the chitosan / polyoxyethylene blended solution with a mass concentration of 3g / mL at a mass ratio of 5:5, and add The cross-linking agent genipin accounting for 1% of the total mass of the mixed sol...

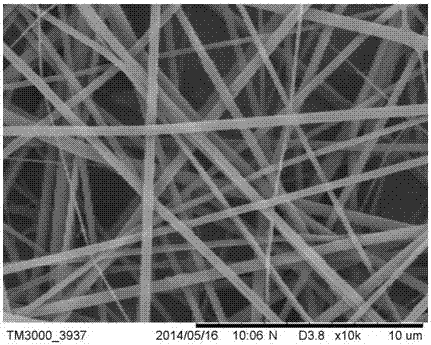

Embodiment 2

[0039] Weigh 0.21g of spongy type I collagen and 0.09g of polyethylene oxide powder and dissolve in 10mL of hexafluoroisopropanol and acetic acid with a volume ratio of 5:5 in a mixed solution, place it on a magnetic stirrer at room temperature and stir completely, and prepare a mass concentration of 3g / mL collagen / polyoxyethylene blend solution; weigh 0.27g chitosan powder and 0.03g polyoxyethylene powder and dissolve them in 10mL acetic acid aqueous solution with a volume fraction of 90%, and stir on a magnetic stirrer at room temperature Transparent, prepare a chitosan / polyoxyethylene blend solution with a mass concentration of 3g / mL.

[0040] Mix the collagen / polyoxyethylene blended solution with a mass concentration of 3g / mL and the chitosan / polyoxyethylene blended solution with a mass concentration of 3g / mL in a mass ratio of 6:4, and add The cross-linking agent genipin accounting for 2% of the total mass of the mixed solution was placed on a magnetic stirrer and stirred...

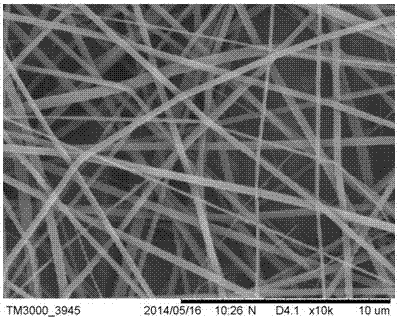

Embodiment 3

[0043] Weigh 0.32g of spongy type I collagen and 0.08g of polyethylene oxide powder and dissolve in 10mL of hexafluoroisopropanol and acetic acid with a volume ratio of 5:5 in a mixed solution, place it on a magnetic stirrer at room temperature and stir completely, and prepare a mass concentration of 4g / mL collagen / polyethylene oxide blend solution; weigh 0.36g chitosan powder and 0.04g polyoxyethylene powder to dissolve together with 10mL acetic acid aqueous solution with a volume fraction of 90%, and stir on a magnetic stirrer at room temperature Transparent, prepare a chitosan / polyoxyethylene blend solution with a mass concentration of 4g / mL.

[0044] Mix the collagen / polyethylene oxide blend solution with a mass concentration of 4g / mL and the chitosan / polyoxyethylene blend solution with a mass concentration of 4g / mL in a mass ratio of 7:3, and add The cross-linking agent genipin accounting for 2% of the total mass of the mixed solution was placed on a magnetic stirrer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com