Chitosan-human recombinant collagen electrostatic spinning nanofiber scaffold and preparation method

A recombinant collagen, electrospinning technology, applied in electrospinning, conjugated synthetic polymer man-made filament, cellulose/protein conjugated man-made filament, etc., can solve the problem of high failure rate, expensive, autologous bone transplantation Material source defects, etc., to achieve the effect of remarkable effect, good fiber morphology, good biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

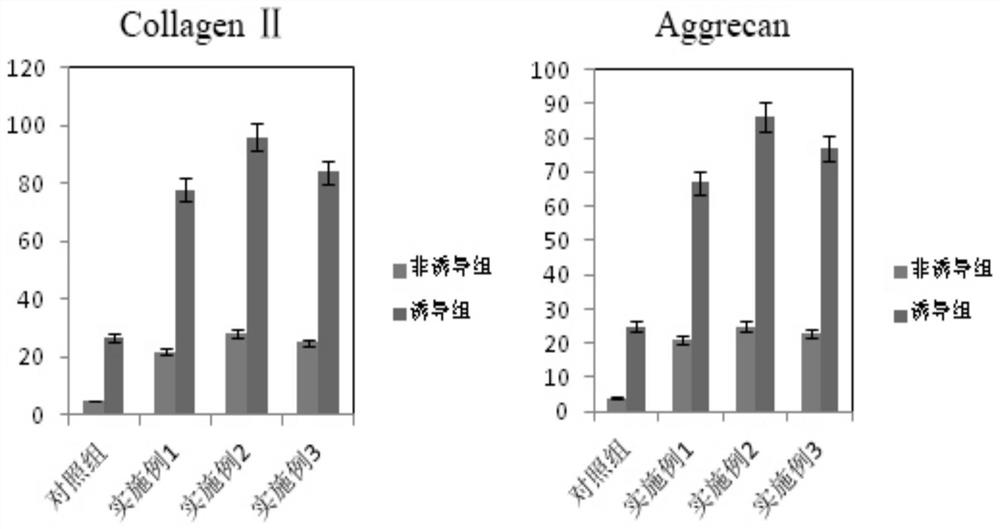

Embodiment 1

[0019] A preparation method of chitosan-human recombinant collagen electrospinning nanofiber scaffold, specifically:

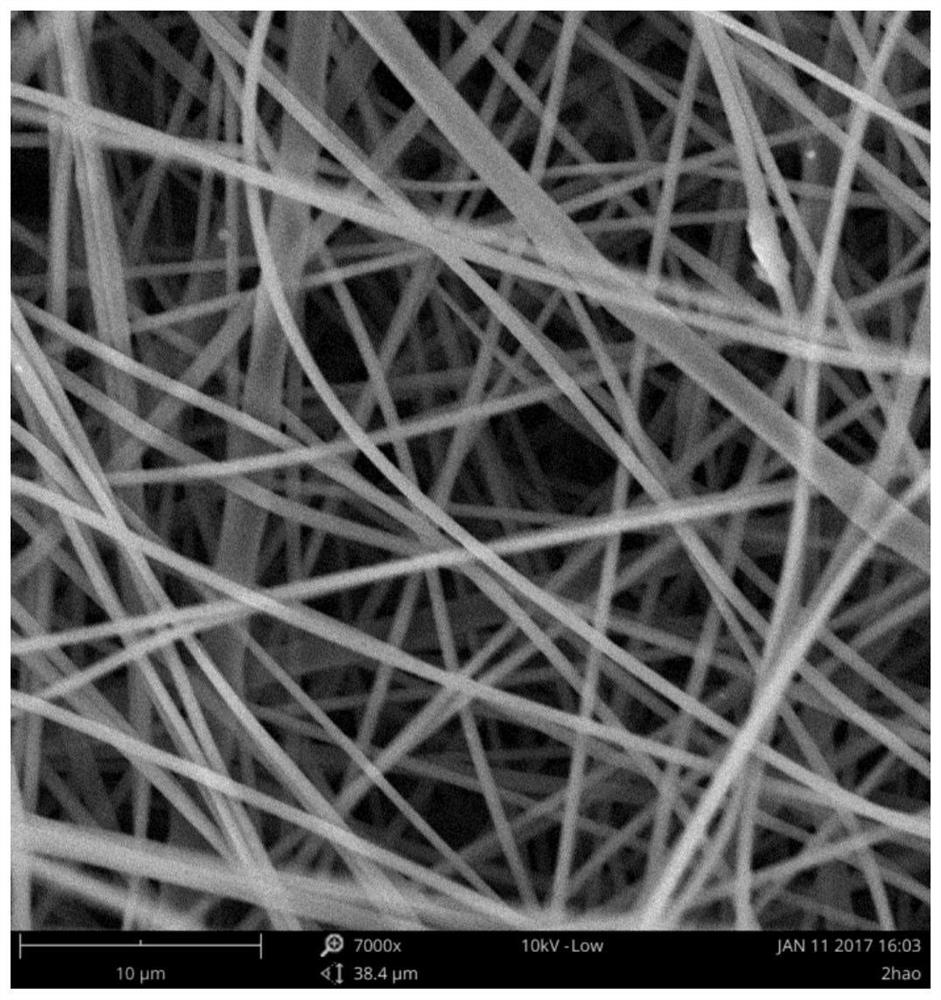

[0020] Calculated by mass percentage, human recombinant collagen is 8%, chitosan is 2.5%, polycaprolactone is 30%, and hexafluoroisopropanol is 59.5%. The three components of human recombinant collagen, chitosan and polycaprolactone were prepared into hexafluoroisopropanol spinning solution, the spinning solution was sucked into the syringe, and the syringe was placed on the electrospinning machine for electrospinning , the spinning voltage was 11kV, the distance between the needle and the receiving plate was 18cm, the propulsion speed of the propulsion pump was 0.5ml / h, and the spinning ambient temperature was 35°C, the electrospun nanofiber scaffold was prepared, and then passed through Aldehyde steam cross-linked for 3 hours to obtain the chitosan-human recombinant collagen electrospun nanofiber scaffold.

[0021] In the experiment, the receiving device wa...

Embodiment 2

[0024] A preparation method of chitosan-human recombinant collagen electrospinning nanofiber scaffold, specifically:

[0025] Calculated by mass percentage, human recombinant collagen is 10%, chitosan is 4%, polycaprolactone is 25%, and hexafluoroisopropanol is 61%. The three components of human recombinant collagen, chitosan and polycaprolactone were prepared into hexafluoroisopropanol spinning solution, the spinning solution was sucked into the syringe, and the syringe was placed on the electrospinning machine for electrospinning , the spinning voltage was 12kV, the distance between the needle and the receiving plate was 20cm, the propulsion speed of the propulsion pump was 0.6ml / h, and the spinning ambient temperature was 38°C. Electrospinning nanofiber scaffolds were prepared by electrospinning technology, and then crosslinked by glutaraldehyde steam for 3 hours to obtain chitosan-human recombinant collagen electrospinning nanofiber scaffolds.

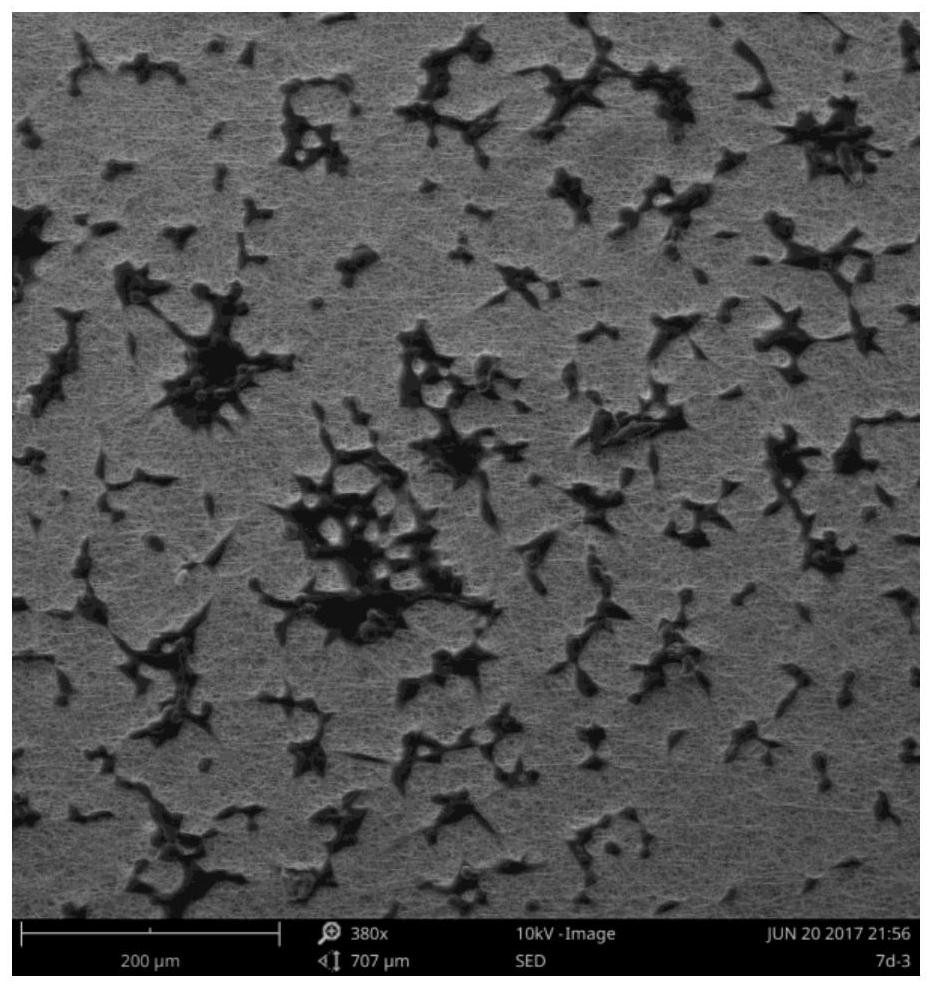

[0026] figure 2 It is a ...

Embodiment 3

[0029] A preparation method of chitosan-human recombinant collagen electrospinning nanofiber scaffold, specifically:

[0030] Calculated by mass percentage, human recombinant collagen is 10%, chitosan is 3%, polycaprolactone is 30%, and hexafluoroisopropanol is 57%. The three components of human recombinant collagen, chitosan and polycaprolactone were prepared into hexafluoroisopropanol spinning solution, the spinning solution was sucked into the syringe, and the syringe was placed on the electrospinning machine for electrospinning , the spinning voltage was 13kV, the distance between the needle and the receiving plate was 23cm, the propulsion speed of the propulsion pump was 0.8ml / h, and the spinning ambient temperature was 40°C. Electrospinning nanofiber scaffolds were prepared by electrospinning technology, and then crosslinked by glutaraldehyde steam for 3 hours to obtain chitosan-human recombinant collagen electrospinning nanofiber scaffolds.

[0031] Wherein, the molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com