Preparing method and application of functional AOPAN-AA nanofiber membrane

A nanofiber membrane and nanofiber technology, applied in the direction of fiber type, fiber treatment, chemical instruments and methods, etc., can solve the problems of small specific surface area of the matrix and few active sites, and achieve low price, significant functionality, and specific surface area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

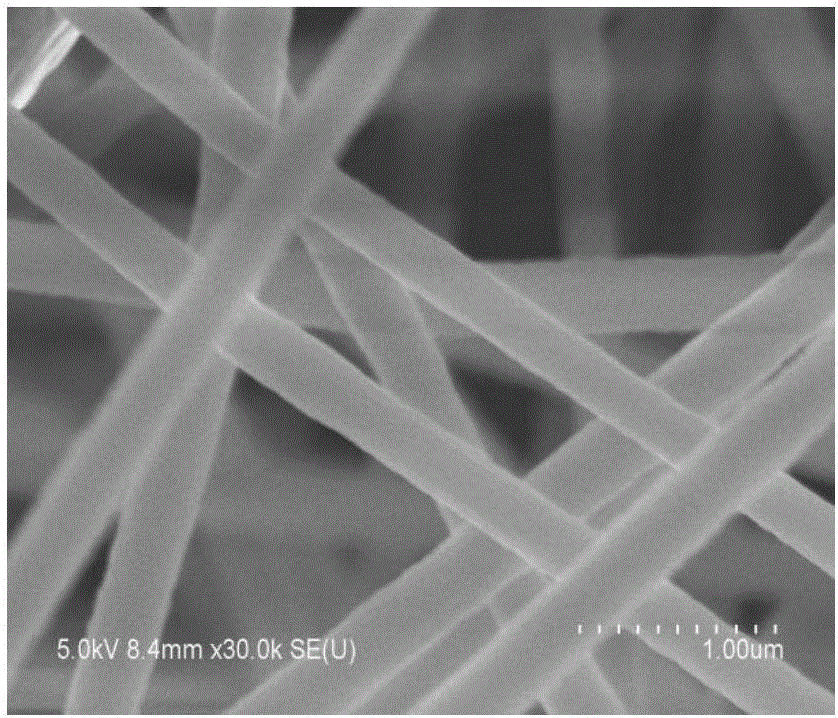

[0031] 1. Dissolve polyacrylonitrile powder (PAN, molecular weight 90,000) in N,N-dimethylformamide (DMF), prepare a spinning solution with a mass fraction of 12%, and perform electrospinning at room temperature. The spinning process parameters were set as follows: spinning speed 0.4mL / h, distance between the spinneret (inner diameter 0.7mm, needle point ground) and aluminum foil receiving plate 15cm, spinning static voltage 18kV, receiving time 10h.

[0032] 2. Soak PAN nanofibers in a hydroxylamine hydrochloride solution with a concentration of 0.2mol / L, a pH of 7, and a temperature of 65°C for 2 hours, then wash them with distilled water for 3-5 times, and dry them in vacuum at 40°C for 2 hours to prepare AOPAN nanofibers. Fiber membrane.

[0033] 3. Immerse 0.4 g of the AOPAN nanofiber membrane prepared in step 2 in 20 mL of tetrahydrofuran (THF) for 10 min, put it into a conical flask filled with 50 mL of tetrahydrofuran (THF), and add 55 μL of 2-bromo - 2-methylpropiony...

Embodiment 2

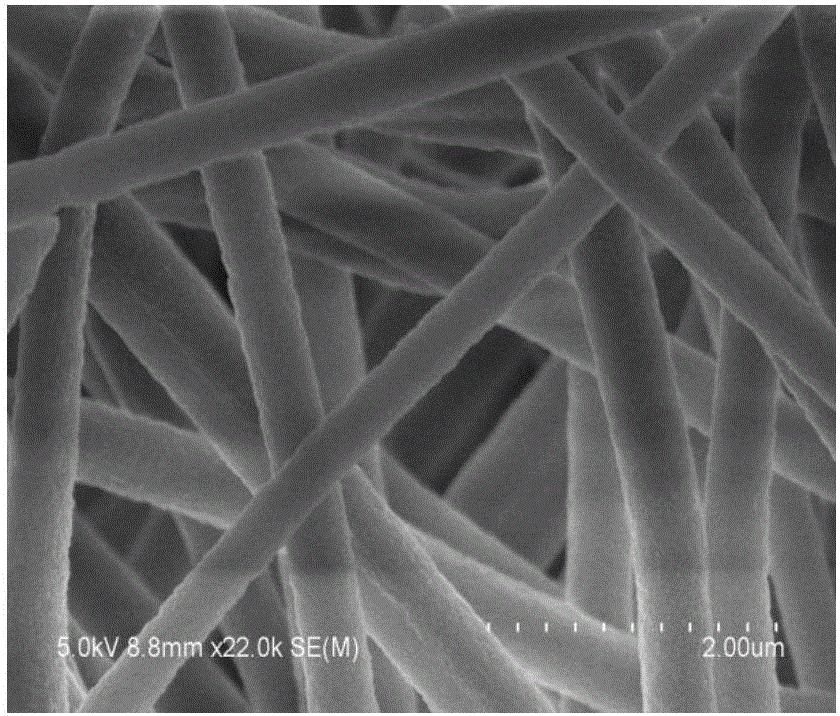

[0037] 1. Dissolve polyacrylonitrile powder (PAN, molecular weight 90,000) in N,N-dimethylformamide (DMF), prepare a spinning solution with a mass fraction of 11%, and perform electrospinning at room temperature. The spinning process parameters were set as follows: spinning speed 0.5mL / h, distance between the spinneret (inner diameter 0.7mm, needle point ground) and aluminum foil receiving plate 17cm, spinning static voltage 19kV, receiving time 12h.

[0038] 2. Soak PAN nanofibers in a hydroxylamine hydrochloride solution with a concentration of 0.2mol / L, a pH of 7, and a temperature of 65°C for 2 hours, then wash them with distilled water for 3-5 times, and dry them in vacuum at 40°C for 2 hours to prepare AOPAN nanofibers. Fiber membrane.

[0039] 3. Immerse 0.2 g of the AOPAN nanofiber membrane prepared in step 2 in 20 mL of tetrahydrofuran (THF) for 10 min, put it into a conical flask filled with 50 mL of tetrahydrofuran (THF), and add 60 μL of 2-bromo - 2-methylpropiony...

Embodiment 3

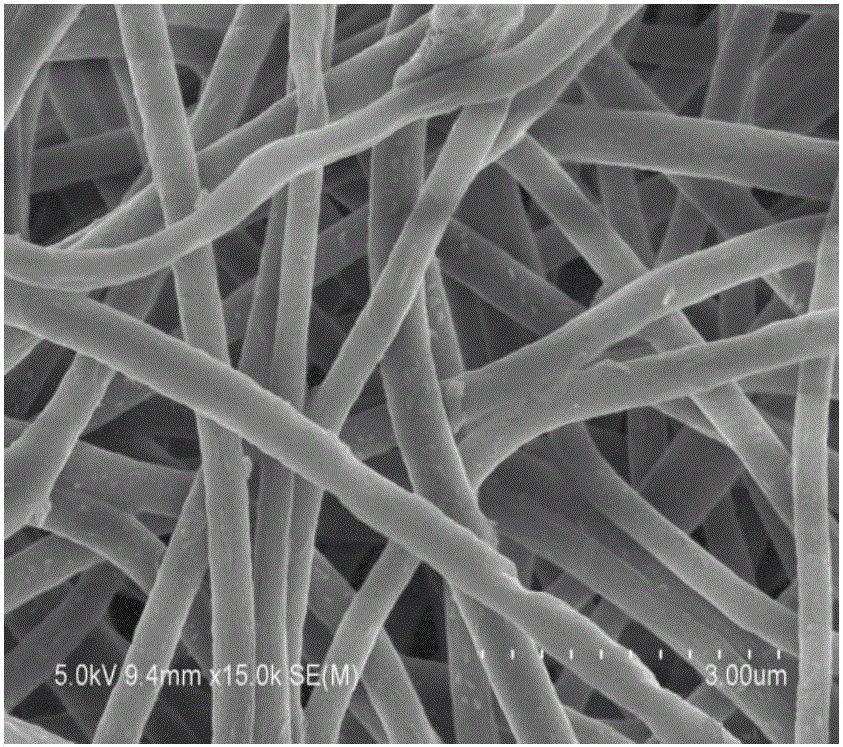

[0043] 1. Dissolve polyacrylonitrile powder (PAN, molecular weight 90,000) in N,N-dimethylformamide (DMF), prepare a spinning solution with a mass fraction of 10%, and perform electrospinning at room temperature. The spinning process parameters were set as follows: spinning speed 0.6mL / h, distance between spinneret (inner diameter 0.7mm, needle point ground) and aluminum foil receiving plate 17cm, spinning static voltage 20kV, receiving time 15h.

[0044] 2. Soak PAN nanofibers in a hydroxylamine hydrochloride solution with a concentration of 0.3mol / L, a pH of 7, and a temperature of 70°C for 2 hours, then wash them with distilled water for 3-5 times, and dry them in vacuum at 40°C for 2 hours to prepare AOPAN nanofibers. Fiber membrane.

[0045] 3. Immerse 0.5 g of the AOPAN nanofiber membrane prepared in step 2 in 20 mL of tetrahydrofuran (THF) for 10 min, put it into a conical flask containing 50 mL of tetrahydrofuran (THF), and add 70 μL of 2-bromo - 2-methylpropionyl bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com