Lithium ferrous phosphate/iron phosphide/carbon composite nanofiber and its preparation method and application

A lithium iron phosphate and nanofiber technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as hindering the application of LiFePO4 materials, complex sol-gel process, and unsatisfactory charge and discharge performance. Effects of good fiber morphology and electrical conductivity, improved spinnability, and excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

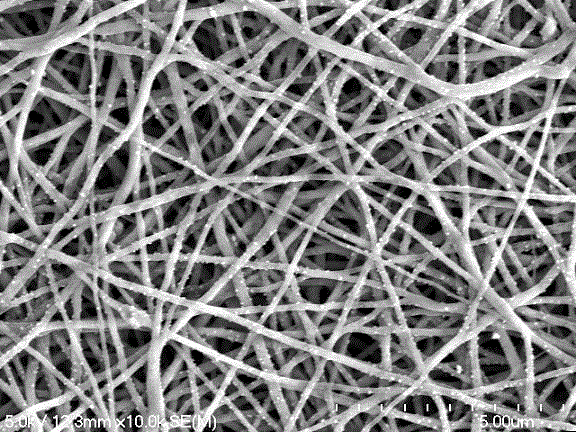

[0033]Dissolve 0.55g of lithium dihydrogen phosphate, 1.76g of iron acetylacetonate, 0.15g of urea and 0.72g of polyvinylpyrrolidone (Mw=1,300,000) in a mixed solvent of 8mL of distilled water and 2mL of ethanol, and stir in a water bath at 60°C for 20 hour, and then added 0.03 g of carbon nanotubes to obtain a spinning solution. When performing electrospinning, the spinning conditions are: the electrospinning voltage is 20kV, the temperature is 30°C, graphite paper is used for collection, the inner diameter of the needle is 0.45mm, and the distance between the needle and the collection device is 15cm. The fibers collected by electrospinning were placed in a tube furnace, heated to 450 ° C for 2 hours to make the reaction occur slowly, and prevent the reaction from occurring too quickly. 4 Influenced by the crystal lattice, the temperature was then raised to 700°C for 5 hours, and finally cooled to room temperature naturally. During the entire heat treatment process, the prote...

Embodiment 2

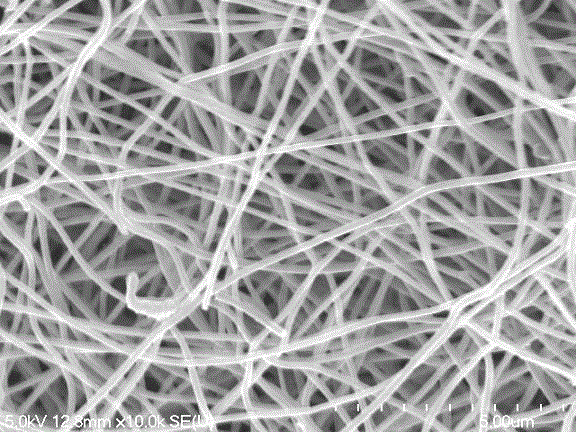

[0035] Dissolve 0.42g lithium hydroxide, 1.05mL concentrated phosphoric acid, 4.66g ferric oxalate, 0.08g glucose and 0.85g polyethylene oxide (Mv=600,000) in a mixed solvent consisting of 6mL distilled water, 3mL ethanol and 1mL acetone, The mixture was stirred for 20 hours under a water bath condition of 50° C. to obtain a spinning solution. When performing electrospinning, the spinning conditions are: the electrospinning voltage is 20kV, the temperature is 40°C, graphite paper is used for collection, the inner diameter of the needle is 0.45mm, and the distance between the needle and the collection device is 30cm. The fiber precursor collected by electrospinning was placed in a tube furnace, heated to 450°C and calcined for 1.5 hours to make the reaction occur slowly and prevent the reaction from occurring too quickly. 4 Influenced by the crystal lattice, the temperature was then raised to 800°C for 4 hours, and finally cooled to room temperature naturally. During the entire...

Embodiment 3

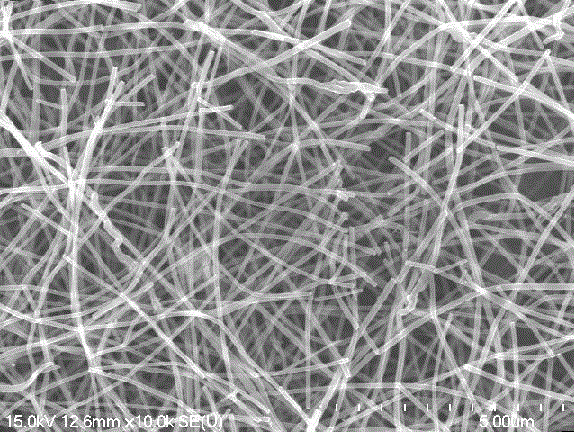

[0037] Dissolve 1.3g of lithium dihydrogen phosphate, 3.0g of ferric citrate, 0.15g of sucrose, 0.75g of polyvinylpyrrolidone (Mw=1,300,000) and 0.50g of polyethylene oxide (Mv=600,000) in 10mL of distilled water at 70 After stirring for 10 hours under the condition of a water bath at °C, 0.02 g of carbon nanotubes was added to obtain a spinning solution. When performing electrospinning, the spinning conditions are: the electrospinning voltage is 30kV, the temperature is 70°C, graphite paper is used for collection, the inner diameter of the needle is 0.45mm, and the distance between the needle and the collection device is 25cm. The fibers collected by electrospinning were placed in a tube furnace, heated to 450 ° C for 2 hours to make the reaction occur slowly, and prevent the reaction from occurring too quickly. 4 Influenced by the crystal lattice, then the temperature was raised to 850°C for 5 hours, and finally cooled to room temperature naturally. During the whole heat tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com