A kind of preparation method of acrylic plate veneer protection base paper

An acrylic board and veneer technology, which is applied in the field of papermaking, can solve the problems of high energy consumption and high cost of raw materials in the beating process, and achieve the effects of shortening the refining time, increasing the profit of the enterprise, and enhancing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

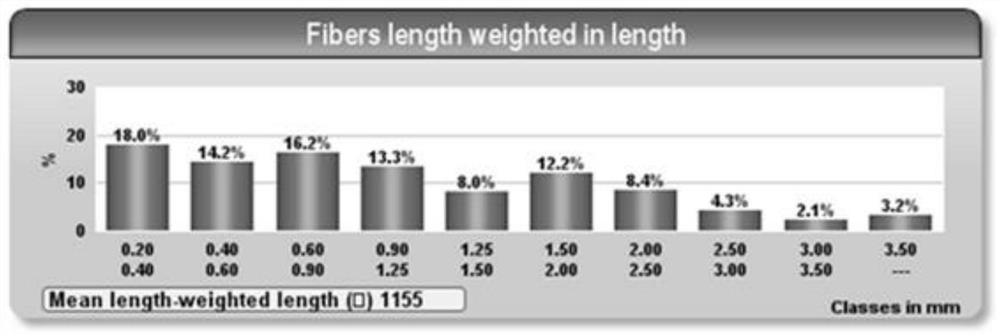

[0032] Embodiment 1: A kind of preparation method of acrylic board veneer protection base paper, carry out according to the following steps: Take 10 parts of cellulase, 8 parts of pectinase, 10 parts of xylanase, 0.8 parts of alkanolamide by weight 0.6 parts, Span-60, 75.7 parts of water, mixed to obtain a compound biological enzyme agent; then put 0.5 parts of coniferous wood pulp board and 0.5 part of hardwood pulp board into the pulper, add 99 parts of water, and the pulp board dissolves Pulp is formed, the water temperature is 25°C, and then relative dry pulp is added to the raw material solution (that is, the dry mass of the pulp in the pulper after removing water; the ratio of the relative dry mass of the softwood pulp board and the hardwood pulp board is the same. It is a conventional parameter, which can be calculated by multiplying the weight of the softwood pulp board or the weight of the hardwood pulp board to calculate the weight of the relative dry pulp) weight 300...

Embodiment 2

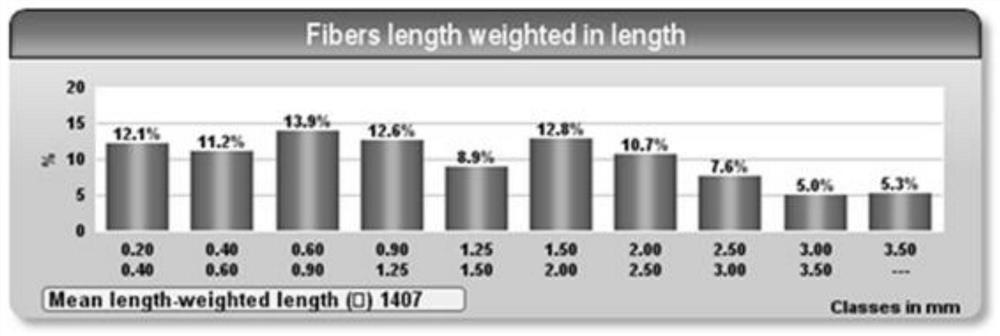

[0033] Embodiment 2: A kind of preparation method of acrylic board veneer protection base paper, carry out according to the following steps: Take 8 parts of cellulase, 6 parts of pectinase, 8 parts of xylanase, 0.7 parts of alkanolamide by weight 0.5 parts of Span-60, 76.8 parts of water, mixed to obtain a compound biological enzyme agent; then put 1.4 parts of coniferous wood pulp board and 0.6 part of hardwood pulp board into the pulper, add 98 parts of water, and the pulp board dissolves To form pulp, the water temperature is 25°C, and then add a compound biological enzyme agent of 250ppm relative to the weight of the dry pulp to the raw material solution for deflaking. The flaking time is 25min. It is 270kw / h, the beating concentration is 2%, the beating degree is 40°SR, and the pulp is obtained. After the above-mentioned processed pulp is subjected to follow-up operations according to the conventional process, after the concentration of the pulp is diluted to 0.4%, it is ...

Embodiment 3

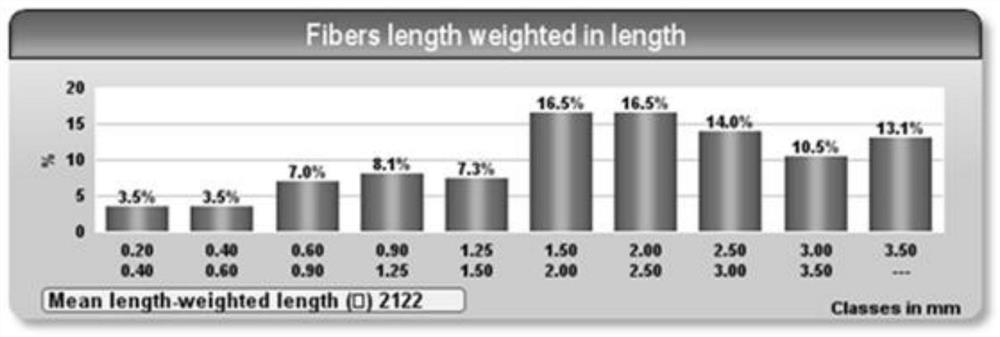

[0034]Embodiment 3: A kind of preparation method of acrylic board veneer protection base paper, carry out according to the following steps: Take 5 parts of cellulase, 2 parts of pectinase, 5 parts of xylanase, 0.5 parts of alkanolamide by weight 0.3 parts of Span-60, 83.2 parts of water, mixed to obtain a compound biological enzyme agent, then put 1.2 parts of coniferous wood pulp board and 0.8 part of hardwood pulp board into the pulper, add 98 parts of water, and the pulp board dissolves To form pulp, the water temperature is 25°C, and then add a compound biological enzyme agent with a relative dry pulp weight of 200ppm to the raw material solution to decompose. The decompression time is 20 minutes, and the decomposed pulp is sent to a refiner for refining. The total power of the refining It is 270kw / h, the beating concentration is 2%, and the beating degree is 35°SR, and the pulp is obtained. After the above-mentioned processed pulp is subjected to follow-up operations acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com