A method for forming multi-component alloy grinding discs with coarse grains on the surface

A multi-element alloy and forming method technology, applied in the field of refining discs for refiners, can solve the problems of the increase in the specific surface area and bonding strength of difficult fibers, the decline in the drainage performance of the slurry, the influence of the average fiber length and the bonding strength, etc. Unground proportion, effect of improving bulk and absorbency, improving fiber drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

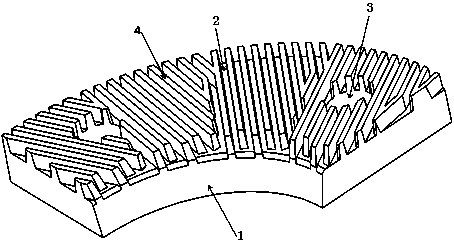

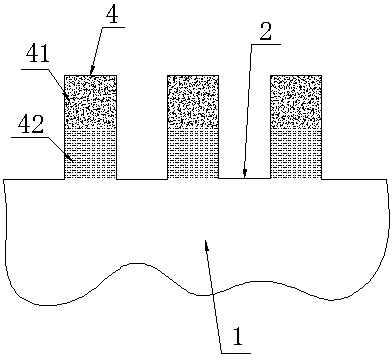

[0033] A method for forming multi-element alloy grinding discs with coarse grains on the surface, such as figure 1 and figure 2 shown, including the following steps:

[0034] 1) Weigh the following components according to the ratio: C= 2%, WC=15%, Cr=30%, Cu=2%, Mn=1.2%, Si=1%, Mo=0.5%, B =5%, the balance is Fe, the above components are mass percentages and the particles of each component are 100 mesh;

[0035] 2) Put it into a clean stainless steel container, add pulp black liquor accounting for about 5% of the total weight of the particles, and stir for 15 minutes to mix the components evenly;

[0036] 3) Using the existing molding manufacturing process, the mixed material is made into a rack 4 with a thickness of 1-3 mm in the required length and shape, and it is dried and hardened at 60 ° C for 2 hours;

[0037] 4) Use the core shooter to make the coated sand mold, and use the coated sand mold as the casting cavity;

[0038] 5) Bond the rack 4 made in step 3) into the...

Embodiment 2

[0046] Except that 140-mesh metal and non-metallic particles are used in step (1), other steps are the same as in Example 1.

Embodiment 3

[0048] Except that the existing 3D printing additive manufacturing process is used in step (3), and the mixed material is made into a rack 4 of required length and shape, other steps are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com