Patents

Literature

36results about How to "Promote filamentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

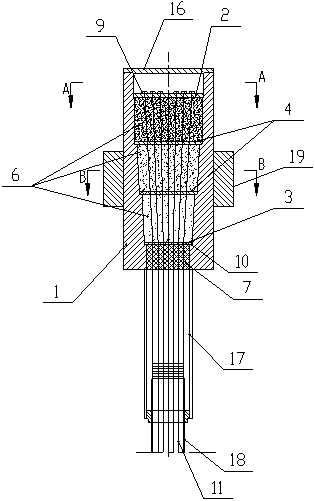

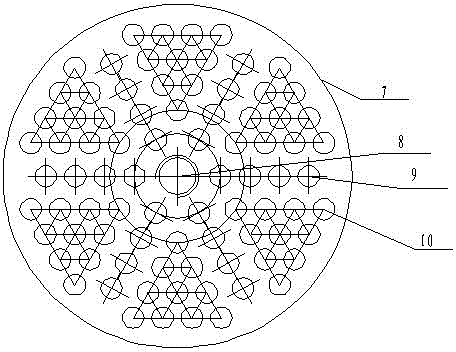

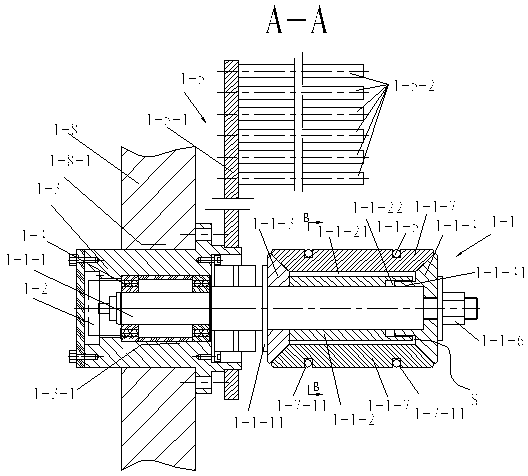

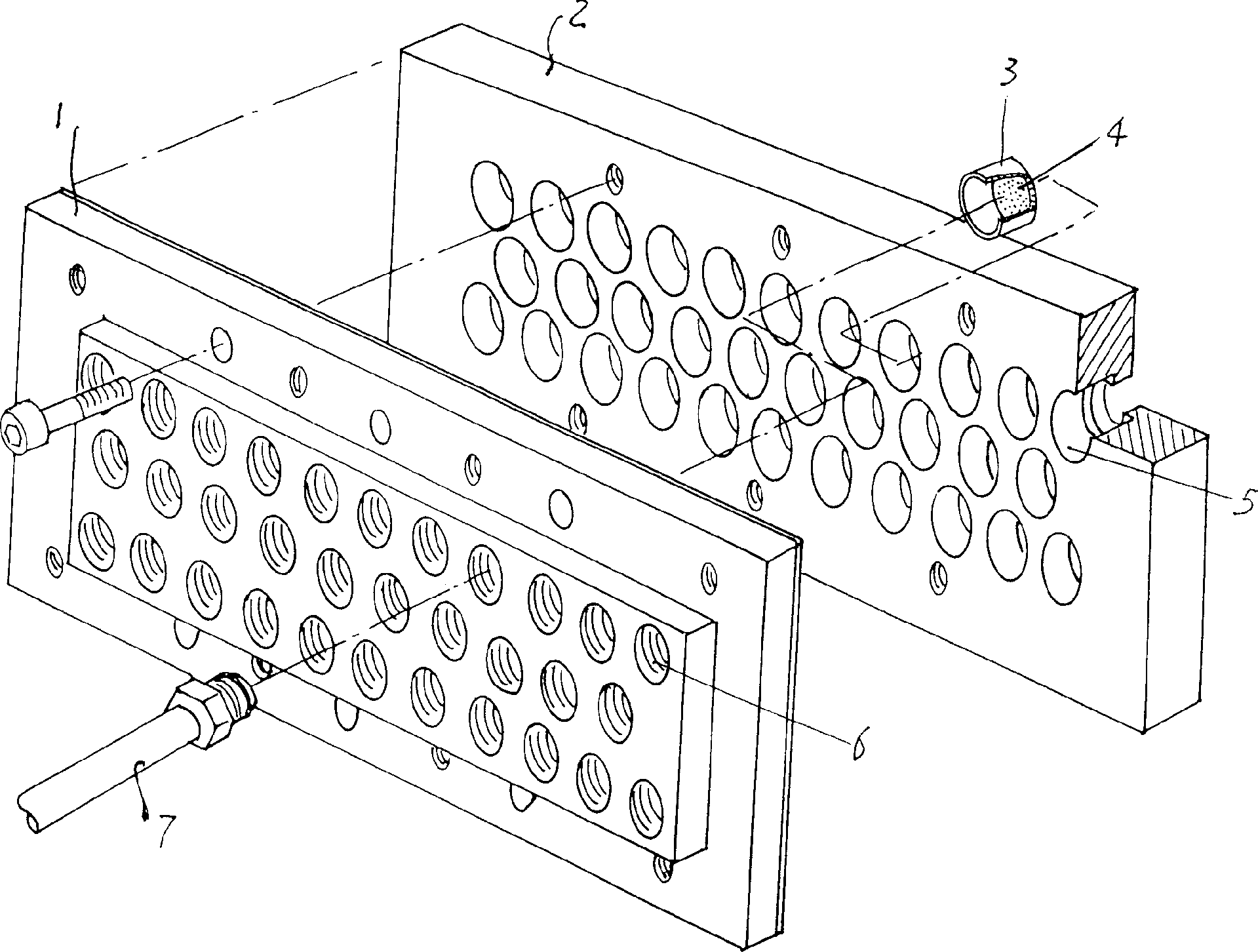

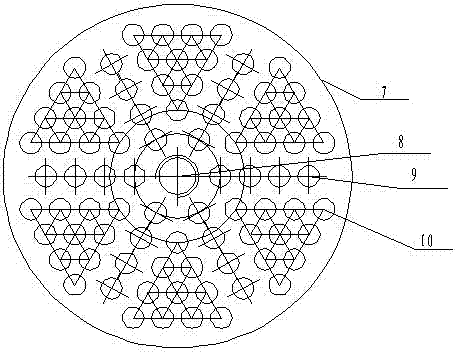

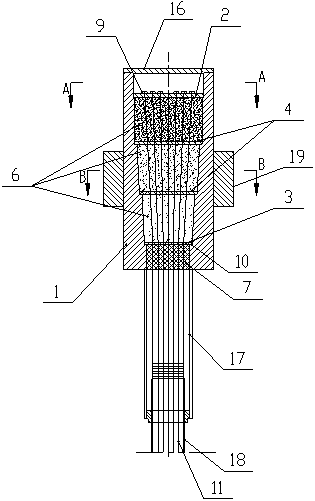

CFRP rib inhaul cable group anchorage device for bridge and manufacturing process of CFRP tendon inhaul cable group anchorage device

ActiveCN105421231AImprove adhesionAvoid shear damageBridge structural detailsEngineeringAluminium oxide

The invention discloses a CFRP rib inhaul cable group anchorage device for a bridge. The device comprises an anchor cup, an upper wire separation end plate, a lower wire separation end plate and multiple wire separation partition plates located between the upper wire separation end plate and the lower wire separation end plate are arranged in the anchor cup, the ends of CFRP ribs penetrate through a wire separation vibration attenuation block, the lower wire separation end plate, all the wire separation partition plates and the upper wire separation end plate in sequence from bottom to top and then are fixed to the upper wire separation end plate, the upper wire separation end plate, the lower wire separation end plate and all the wire separation partition plates are each provided with wire separation holes allowing the CFRP rib to pass through, each wire separation hole is internally provided with a gasket, the space formed by the upper end plate, the lower end plate and the inner wall of the anchor cup is divided into multiple filling chambers by the wire separation partition plates, and each filling chamber is filled with rubber mass. According to the CFRP rib inhaul cable group anchorage device, the wire separation end plates and the wire separation partition plates are arranged in the anchor cup, so that wire separation and fixation for the CFRP ribs are facilitated, meanwhile, the anchorage device is separated into the multiple filling chambers, the rubber mass in each filling chamber is made of hard particles with different yields, such as iron sand particles or aluminum oxide particles, rigidity of the rubber mass is adjusted to be increased gradually from the lower end of the anchorage device to the upper end of the anchorage device, the device is adapted to the anchoring loading features of the CFRP ribs, and the anchoring force of the CFRP ribs is raised.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

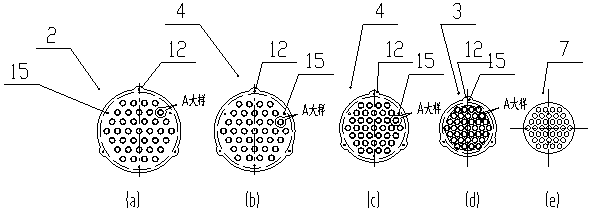

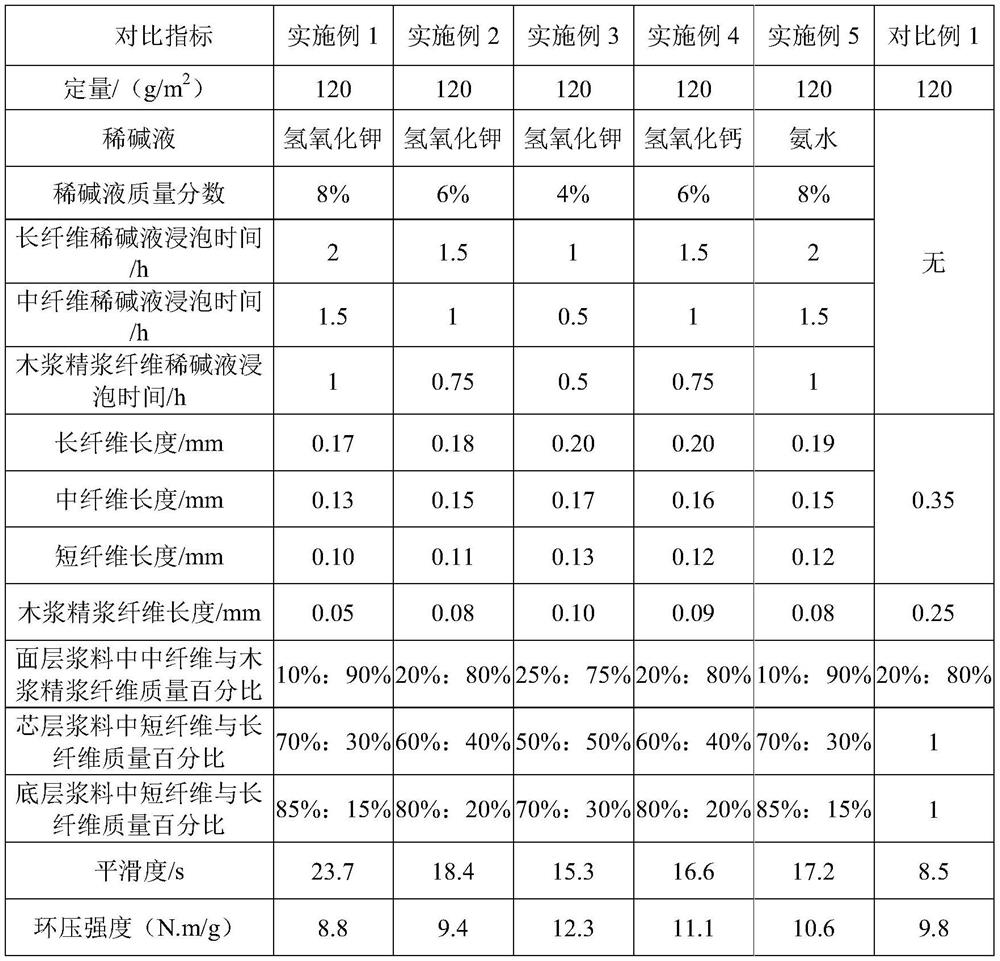

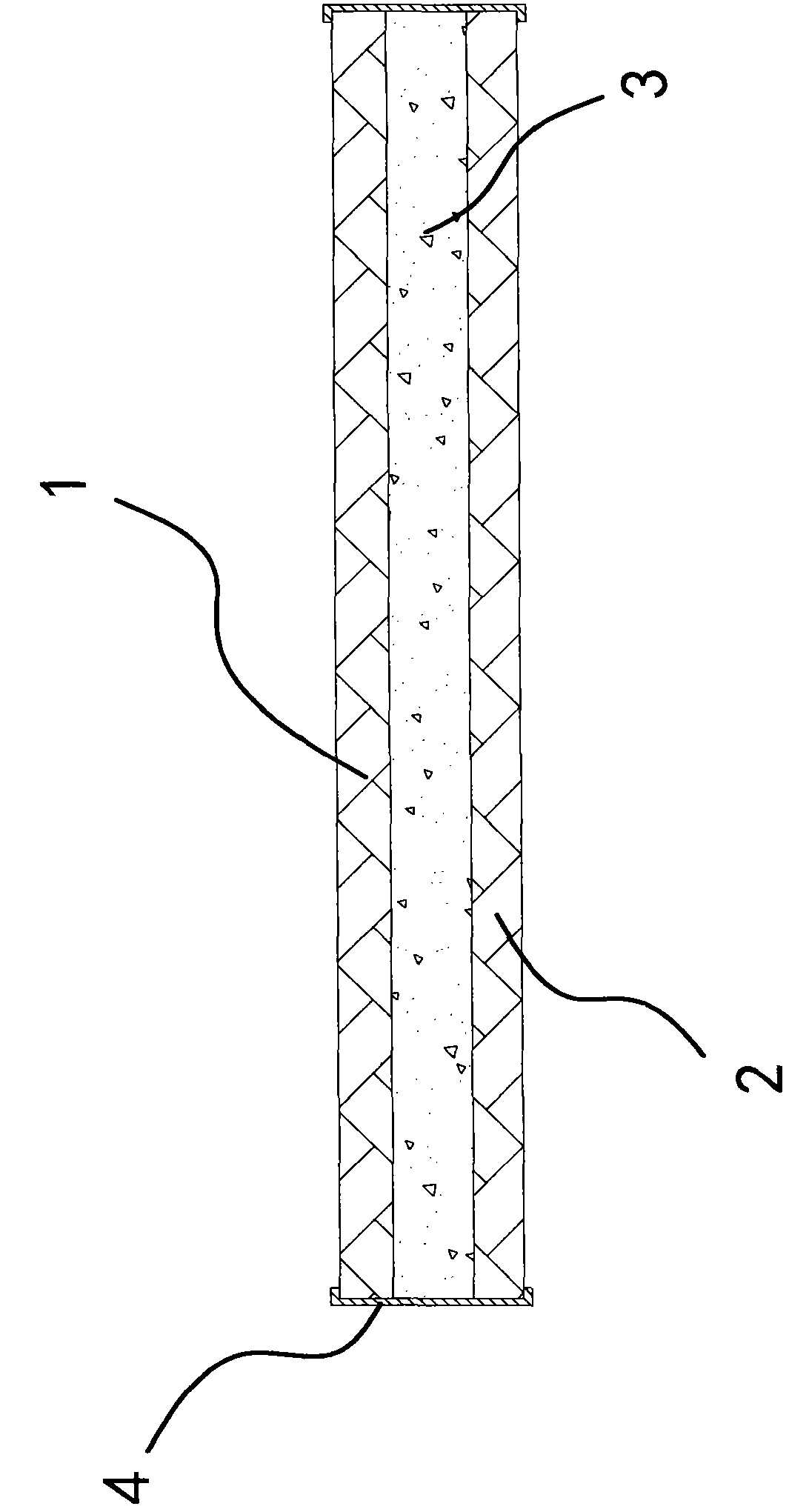

Production method of recycled case board paper

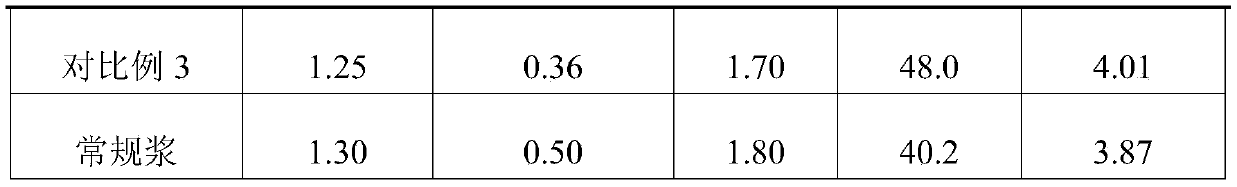

PendingCN107460784AImprove beating degreeImprove bindingFlexible coversWrappersFiberFolding endurance

The invention relates to a production method of recycled case board paper. The recycled case board paper comprises a paper body, wherein the paper body sequentially comprises a face layer, a core layer and a bottom layer from top to bottom. The production method sequentially comprises the following steps of face layer raw material preparation in proportion, first time of pulping, first time of defibrination, core layer and bottom layer preparation in proportion, second time of pulping, second time of defibrination, bottom layer pulp preparation, core layer pulp preparation, mesh forming, squeezing, first time of drying, aspersive application on the surface, second time of drying, press-polishing and rolling and slitting. The production method has the advantages that a paper anti-burst agent is added in mesh forming and increases the contact area with fiber, more hydrogen bonds are formed for bonding, the bonding power of the fiber is improved, fiber cutinization is retarded, the folding endurance of the case board paper is improved, it is ensured that no shedding occurs on the surface after the paper is reused for multiple times, accordingly the damage rate of a smokebox is reduced, the one-time cyclic use rate of the smokebox is improved, it is ensured that the strength of paper cartons is not reduced and the cartons are not damaged after the paper is reused for multiple times, and secondary use is not affected.

Owner:ZHEJIANG JINGXING PAPER

Physical preparation method for bamboo fibers

InactiveCN105316770AShort processReduce manufacturing costMechanical fibre separationHigh pressureFiber

The invention provides a pure physical and pollution-free extraction technology for bamboo fibers. By means of the technology, coarse bamboo fibers with the diameter ranging from 0.03 mm to 0.3 mm, the length larger than 20 cm, the elongation at break ranging from 3% to 7%, the break force ranging from 3 N to 15 N and the break strength ranging from 100 MPa to 600 MPa can be obtained. The technological process includes the steps of pretreatment, high-temperature and high-pressure cooking, mechanical softening fibrillation, screening and separation, drying, and packaging and warehousing, wherein pretreated bamboo chips are put into a cooking container to be cooked and softened for 14-15 h, and then mechanical grinding fibrillation is performed through a softening machine. The product prepared through the technology meets the requirement for bamboo-plastic composites, production cost is low, the technological process is short, cleanliness and environment friendliness are achieved, and preparation is simple and easy.

Owner:TIANJIN POLYTECHNIC UNIV

Production method of craft paper with high smoothness

InactiveCN111945471AReduce manufacturing costProtect environmentFlexible coversWrappersPulp treatmentPapermaking

The invention discloses a method for producing craft paper with high smoothness. The method comprises the following procedures of: (1) a waste paper treatment procedure; (2) a wood pulp treatment procedure; and (3) a net papermaking procedure. In the procedure (1), waste paper pulp is subjected to impurity removal and grading so as to obtain long fiber pulp, medium fiber pulp and short fiber pulp;in the procedure (2), repulping is conducted to obtain wood pulp, the long fiber pulp, the medium fiber pulp and the wood pulp are soaked in dilute alkali liquor, and different types of abrasive discs for disc milling are prepared under an alkaline condition to obtain corresponding refined pulp; the refined medium fiber pulp is mixed with the refined wood pulp to obtain surface-layer pulp, and the refined short fiber pulp is mixed with the refined long fiber pulp to obtain core-layer pulp and bottom-layer pulp; paper manufacturing with the pulp is conducted in a triassic mesh mode; and finally, squeezing, drying, calendaring, reeling, rewinding and packaging are sequentially performed to obtain a finished product. In the process of pressing, the surface of coarse cotton cloth contains a modal fiber layer, and shape memory fibers are wrapped in the modal fiber layer. The production method effectively improves the smoothness of the craft paper.

Owner:NINE DRAGONS PAPER IND TIANJIN

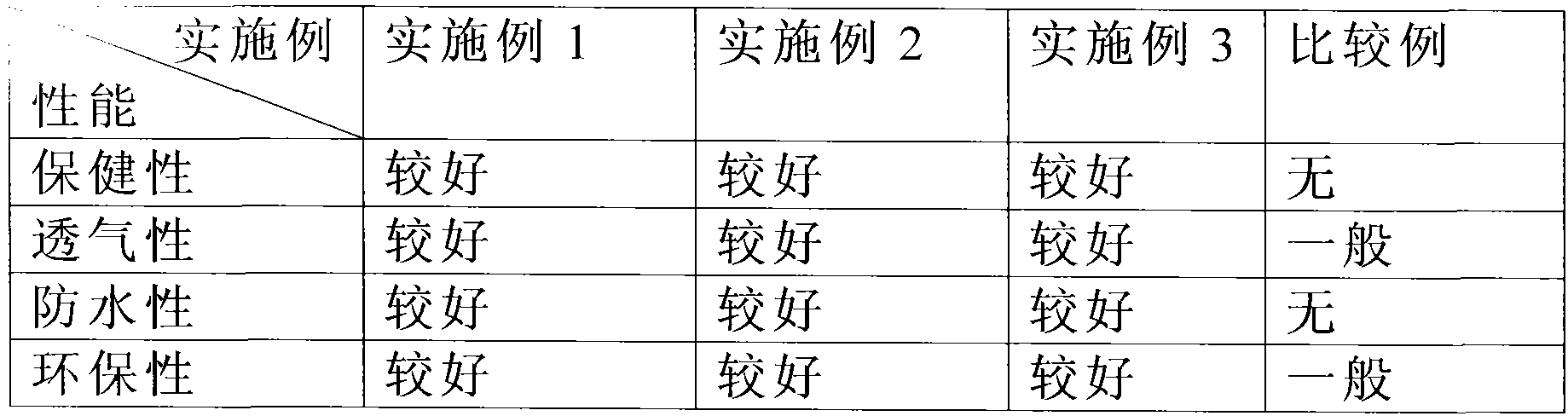

Health care mat for infants and manufacturing method thereof

InactiveCN103405088APowerful insecticidePromote circulationNervous disorderImmunological disordersTraditional medicineSemen

The invention provides a health care mat for infants and belongs to the technical field of textile processing. The health care mat for infants is of a three-layer double-side structure, a front side layer and a back side layer are both a simulation rattan mat body, and a middle health care layer is formed by evenly mixing and flattening 100 parts of Chinese herbal medicine and 5-40 parts of natural rubber cement by weight. The Chinese herbal medicine of the health care layer includes the following raw materials by weight: 1 part to 10 parts of bamboo charcoal, 1 part to 10 parts of jasmine flower, 20-35 parts of negundo chastetree fruit, 10-30 parts of semen cassiae, 10-30 parts of lavender and 10-20 parts of mint. The manufacturing method includes manufacturing the simulation rattan mat bodies, taking the Chinese herbal medicine according to the prescription, drying and breaking the Chinese herbal medicine, mixing the dried and broken Chinese herbal medicine with the natural rubber cement to obtain the health care layer, evenly coating the natural rubber cement on the bottom face of one simulation rattan mat body, laying the health care layer, then laying the other simulation rattan mat body and conducting clipping and edge wrapping to obtain a finished product of the health care mat for the infants. The health care mat is good in health care effect and low in cost.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

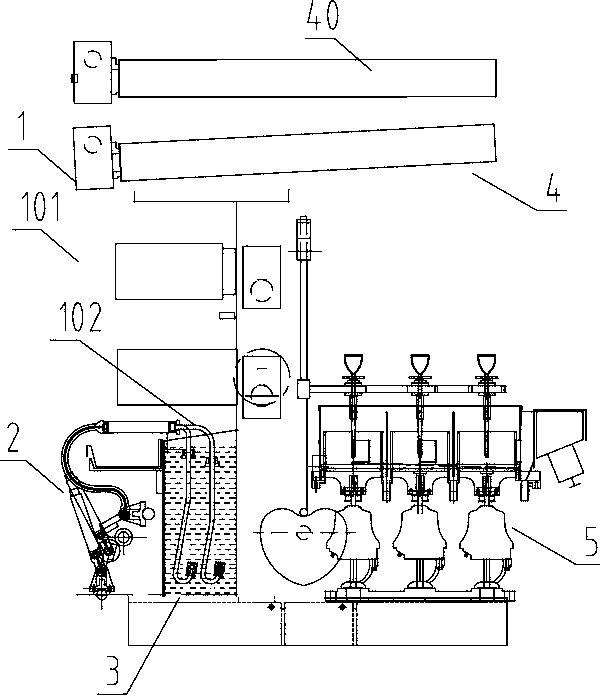

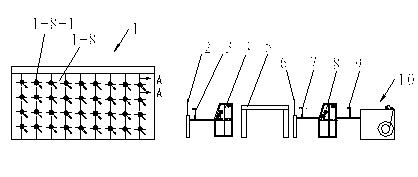

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

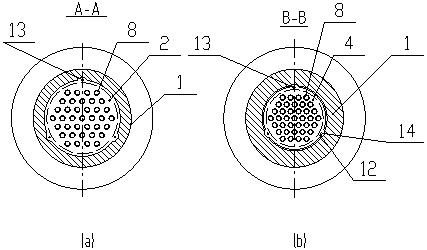

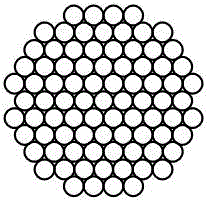

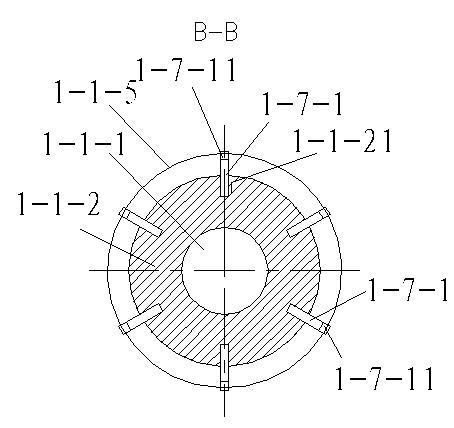

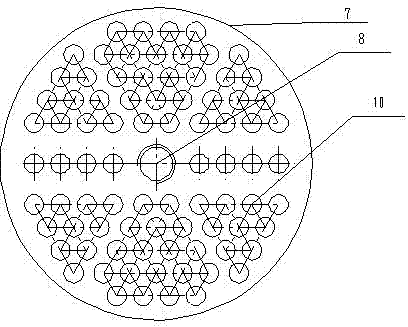

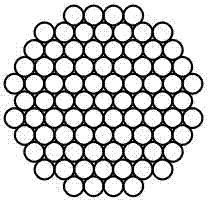

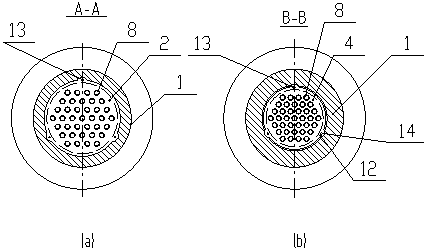

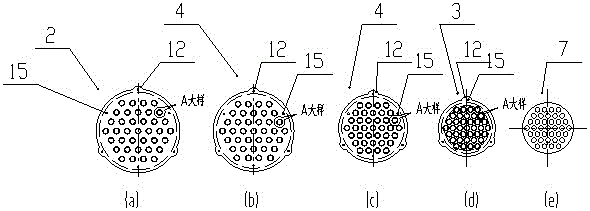

Wire dividing plate of cold cast anchorage and wire dividing method thereof

ActiveCN102747683AReduce manufacturing costExtended service lifeBridge structural detailsBridge erection/assemblyEngineering

The invention provides a wire dividing plate of a cold cast anchorage, which comprises a wire dividing plate main body. The wire dividing plate main body is a plane; a screw hole is arranged at the center of the wire dividing plate; six lines of holes arranged in a straight line and six groups of holes in regular triangle arrangement are evenly distributed along the circumference of the screw hole in a radial manner; and the straight-line holes and the regular triangle hole groups are alternately arranged. The wire dividing method includes the following steps of: bundling semi-parallel steel wires into a regular hexagonal or chamfer hexagonal shape in tight arrangement; in the wire dividing process, inserting an awl along the interlayer of a steel wire bundle, then inserting three rows of thin steel wires with appropriate diameter, wherein the angle between every two rows of thin steel wires is 120degrees; replacing the two thin steel wires at the middle of each row of steel wires with thick steel wires, adjusting the axial positions of the thin and thick steel wires so as to enable the tips of the steel wires to be in arrangement consistent with the holes of the wire dividing plate; buckling the wire dividing plate into the steel wire bundle, jacking the wire dividing plate to an appropriate position through a pipe-jacking for the convenience of upsetting the steel wires, upsetting the steel wires, pulling back the wire dividing plate, and conducting the treatments of sealing, pouring, vibrating and curing. The wire dividing plate has the characteristics of high production efficiency, good anchoring performance and long service life.

Owner:JULI SLING

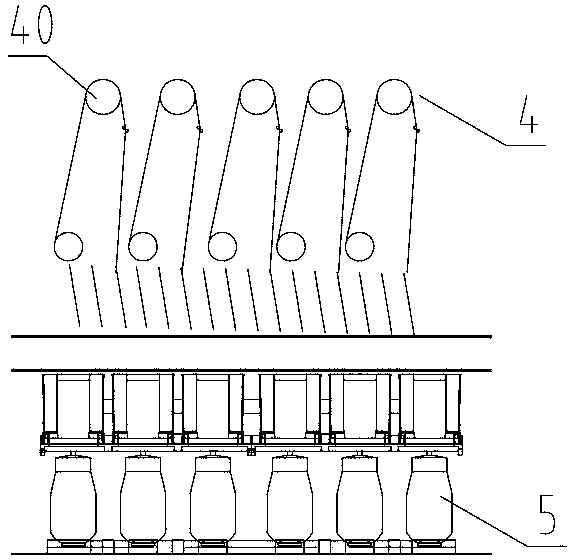

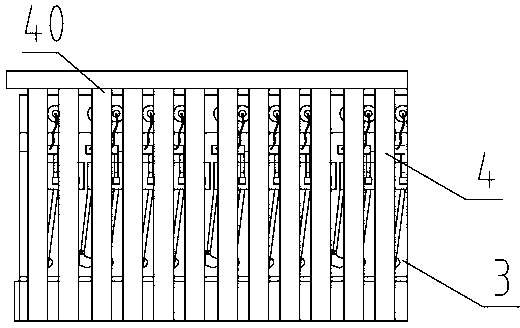

Silk separating and warping equipment

InactiveCN102995205APrevent radial movementTighten and firmCreelsWarping machinesYarnProcess engineering

The invention discloses silk separating and warping equipment. The silk separating and warping equipment comprises a drive yarn feeding creel and a warping machine. The silk separating and warping equipment is characterized in that the subsequent device of the drive yarn feeding creel further comprises a yarn collecting plate, a yarn needle collecting assembly, a first tension roller device, a silk separating frame, a silk separating plate, a silk separating needle assembly, a second tension roller device and a warping needle assembly which are sequentially connected, a plurality of yarn collecting holes are formed on the yarn collecting plate, and a plurality of silk separating holes are formed on the silk separating plate; the drive yarn feeding creel comprises a creel body, a tension device, a motor, an installation sleeve and an installation bearing; and the silk separating creel comprises a support, a plurality of silk separating rod assembly, a left silk separating rod seat and a right silk separating rod seat. Silk separating and warping processes can be realized through one equipment, so that cost and labor are saved; and moreover, drive unreeling is adopted during the silk separating process, so that the product quality is improved.

Owner:CHANGZHOU CHANGHAN MACHINERY

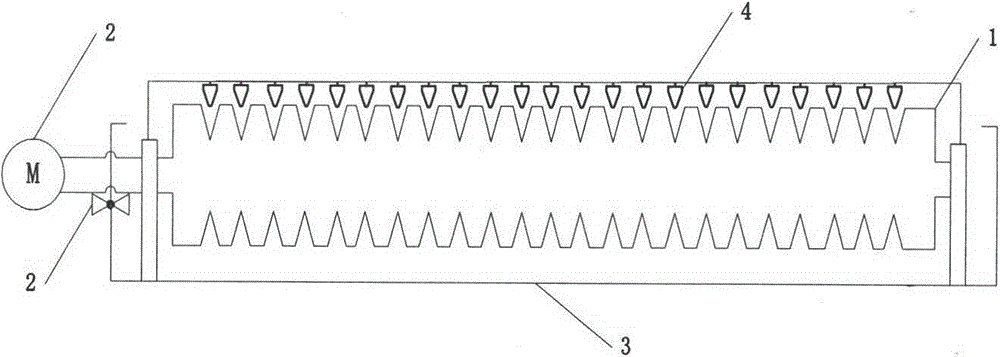

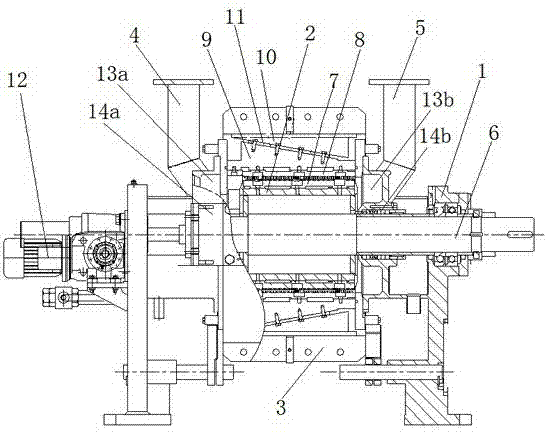

Cylindrical pulping machine with double pulping areas

InactiveCN103061189AStable refining performanceEnhanced interactionPulp beating/refining methodsSlide plateEnergy consumption

The invention discloses a cylindrical pulping machine with double pulping areas. The cylindrical pulping machine with the double pulping areas comprises racks, a rotor, a casing, a pulp inlet tube, a pulp outlet tube, a driving shaft, a feeding transmission mechanism and a pulping mechanism, wherein the pulping mechanism comprises a plurality of movable pulping pieces, axial moving slopes, a fixed pulping piece and a fixed pulping piece moving slider, the movable pulping pieces are mounted on the rotor and used for forming cylindrical pulping areas, the axial moving slopes are fixedly connected with the casing, sliding plates capable of converting axial moving into radial moving of the fixed pulping piece are arranged between the axial moving slopes and the fixed pulping piece moving slider, the casing is connected with an output end of the feeding transmission mechanism, and the driving shaft is connected with a motor supplying power. The cylindrical pulping machine with the double pulping areas has the advantage that pulping quality is improved, pulping state is stable, and performance of pulp is improved. Compared with a conventional dual-disc pulping machine and a conventional conical pulping machine, the cylindrical pulping machine with the double pulping areas also has the advantage that empty load energy consumption is greatly lowered and economic benefit is remarkable under same pulping capability.

Owner:SUZHOU FEIYU PRECISION TECH

Preparation method of soluble and fusible polyimide precipitation fiber

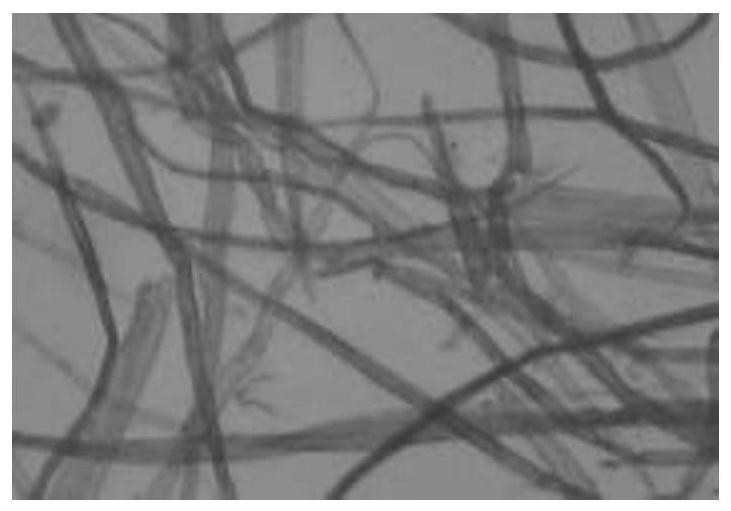

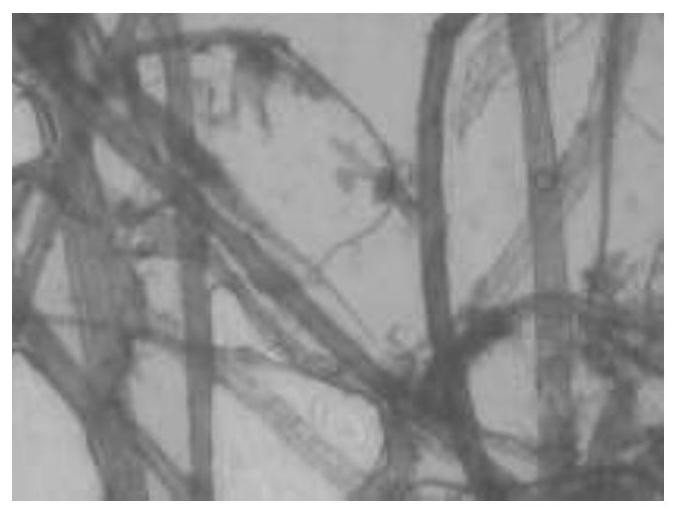

ActiveCN107881579AGood dispersionPromote filamentationSynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentFiberStock solution

The invention discloses a preparation method of a soluble and fusible polyimide precipitation fiber. The preparation method comprises the following steps: firstly, mixing calcium chloride, N,N-dimethylacetamide and water in proportion, and uniformly stirring, so that a precipitation agent is obtained; secondly, carrying out reaction on a diamine monomer and a dianhydride monomer in an aprotic polar solvent to generate polyamide acid solution, then carrying out chemical cyclodehydration to obtain polyimide solution, and finally diluting to obtain polyimide stock solution; and thirdly, respectively injecting the precipitation agent and the polyimide stock solution into a precipitation machine, carrying out high-speed stirring by virtue of the precipitation machine, shearing to obtain suspension liquid, and then filtering and washing, so that the soluble and fusible polyimide precipitation fiber is obtained. The prepared polyimide precipitation fiber not only can well meet wet papermakingrequirement but also can be fused, so that the polyimide precipitation fiber can be tightly combined with a polyimide chopped fiber during hot press molding, and finally the polyimide precipitation fiber can be applied to preparation of high-performance high-temperature-resistant paper products such as high-strength lithium ion diaphragm paper, capacitor paper, insulation paper and honeycomb paper.

Owner:CHANGZHOU SUNCHEM HIGH FORMANCE POLYMER

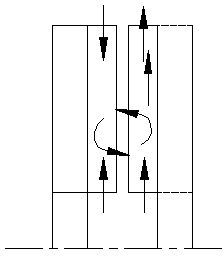

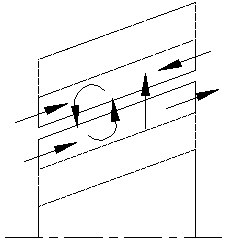

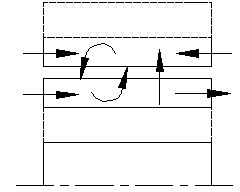

Thread spraying structure

The present invention belongs to the field of spinning technology, and is especially one kind of spinning mechanism for spinning various kinds of artificial fiber. The spinning mechanism includes spinning plate seat, spinning plate, spinning cap seat cavity on the spinning plate and spinning cap with fine spinning orifices, and features that it includes also one rotating unit, which is rotated with one drive unit and is stretched into spinning cap seat cavity, and one spinning cap seat, which is configured onto the rotating unit and has spinning cap inside it. One of the advantages is that the rotating spinning cap seat and spinning cap makes the spun tow rotation twisted and makes broken tow taken out to avoid winding on the roller; and the other is that the spun filaments twisted separately without mutual tangling, being favorable to tow separation.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

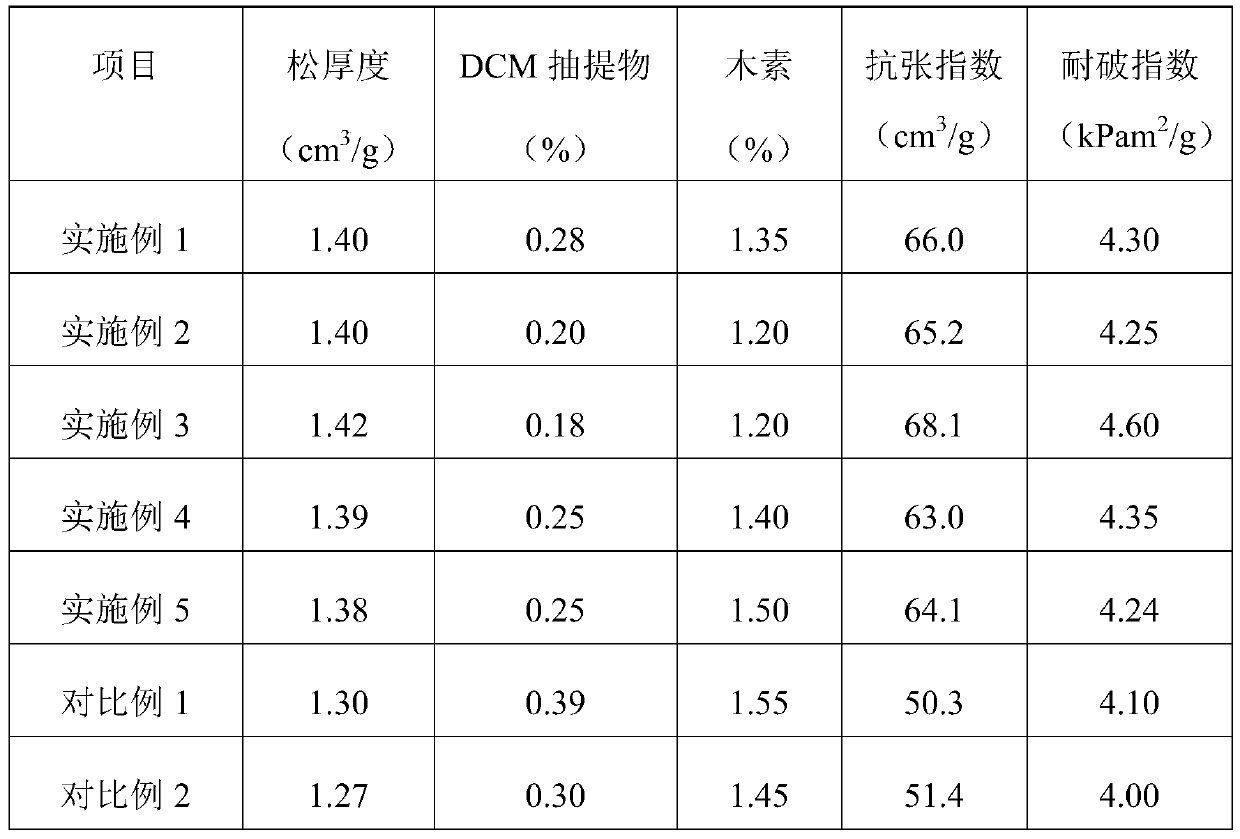

Preparation method of sulfate acacia wood pulp with high bulk and low extract

InactiveCN110644272AHigh burst resistanceIncreased tearingDigestersPulp bleachingWhite rotWhite rot fungus

The invention provides a sulfate acacia wood pulp with high bulk and low extract, and a preparation method thereof. Cacia mearnsii De Wild. and Acacia crassicarpa Benth. are combined according to a reasonable ratio. The preparation method comprises the following steps: material preparation, soaking, cooking, oxygen bleaching, four-stage bleaching, screening and pulp board making. The method reduces the consumption of DCM extract and chemicals by spraying white rot fungi, and optimizes the four-stage bleaching process, and the prepared paper pulp has the advantages of high bursting strength, high tearing strength, high tensile index, high bulk and extract reduction.

Owner:HAINAN JINHAI PULP & PAPER

Tobacco stem multistage utilization method based on supercritical CO2 extraction technology

ActiveCN111789283APromote filamentationImprove utilizationTobacco preparationTobacco treatmentTobacco productTobacco leaf

The invention discloses a tobacco stem multistage utilization method based on a supercritical CO2 extraction technology. The invention provides a comprehensive utilization method of tobacco stems. Firstly, the tobacco stems are extracted through the supercritical CO2 extraction technology, the tobacco stems treated through the supercritical CO2 extraction technology are loose in structure, later fiber fibrillation is facilitated, energy consumption is reduced, and the fiber utilization effect is improved; the extract liquor in a primary separation kettle is rich in tobacco pigment and is usedfor producing reconstituted tobaccos after being separated and collected, so that the coloring effect of the reconstituted tobaccos can be improved, and the appearance quality of products is improved;aroma components in the extraction liquid in the secondary separation kettle are from the tobacco stems, the aroma characteristics are consistent with those of tobacco, and the aroma components are added into the coating liquid after being subjected to secondary separation and purification, so that the sensory quality of reconstituted tobacco products can be effectively improved.

Owner:HUBEI CHINA TOBACCO IND +1

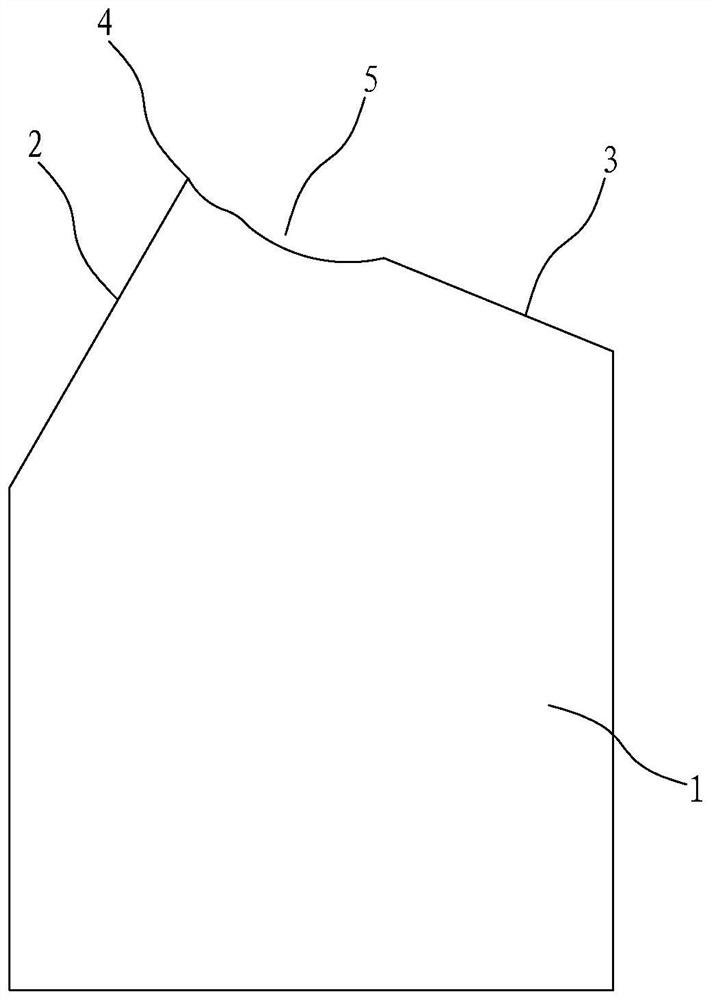

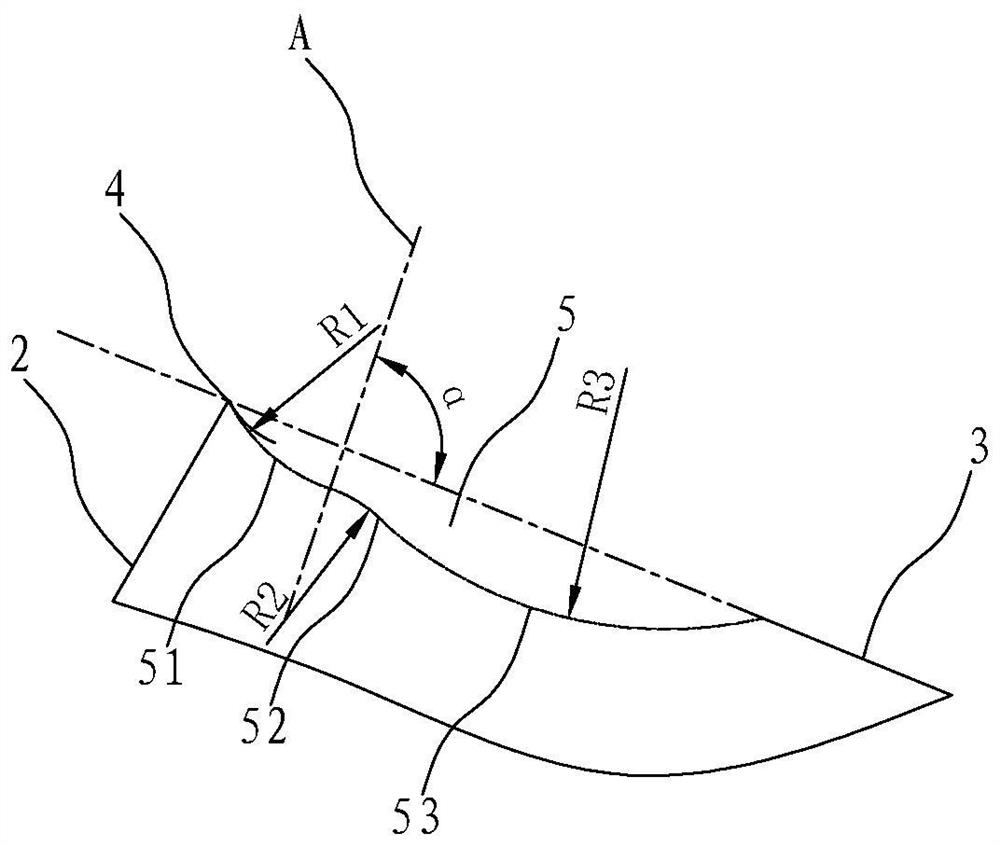

A polymer monofilament liquid applying (oil applying, functional sizing agent applying and wrapping) device

InactiveCN105887219AIncrease the contact areaSolve the problem of low liquid volumeArtificial filament physical treatmentFilament/thread formingPhysicsEngineering

The invention provides a polymer monofilament liquid applying (oil applying, functional sizing agent applying and wrapping) device. The device mainly comprises a liquid applying and filament guide channel assembly 1, a liquid applying and filament guide channel assembly drive device 2, a liquid storage assembly 3, a liquid quantitative conveying assembly 4 and an overflow assembly 5. A liquid applying and filament guide assembly channel can be in the shape of a flat surface or a curved surface; the carrier thereof can be roller-shaped or wheel-shaped and is fixed on a liquid applying and filament guide member base. The drive device 2 is connected to one end of the liquid applying and filament guide channel assembly. The liquid applying and filament guide channel assembly is characterized in that a liquid applying surface is provided with liquid guide grooves of different shapes and specifications. The device is simple in structure; the liquid applying surface processing precision and fineness are high, and damage to polymer monofilaments can be reduced; the liquid applying uniformity in the radial direction and the axial direction of the monofilaments can be guaranteed and the liquid applying efficiency is increased; the device can fulfill the functions of a filament guide device and a filament separating device and can be used for the liquid applying (oil applying, functional sizing agent applying and wrapping) of various kinds of polymer monofilament materials.

Owner:JIANGSU DUWEI NEW MATERIAL SCI & TECH CO LTD

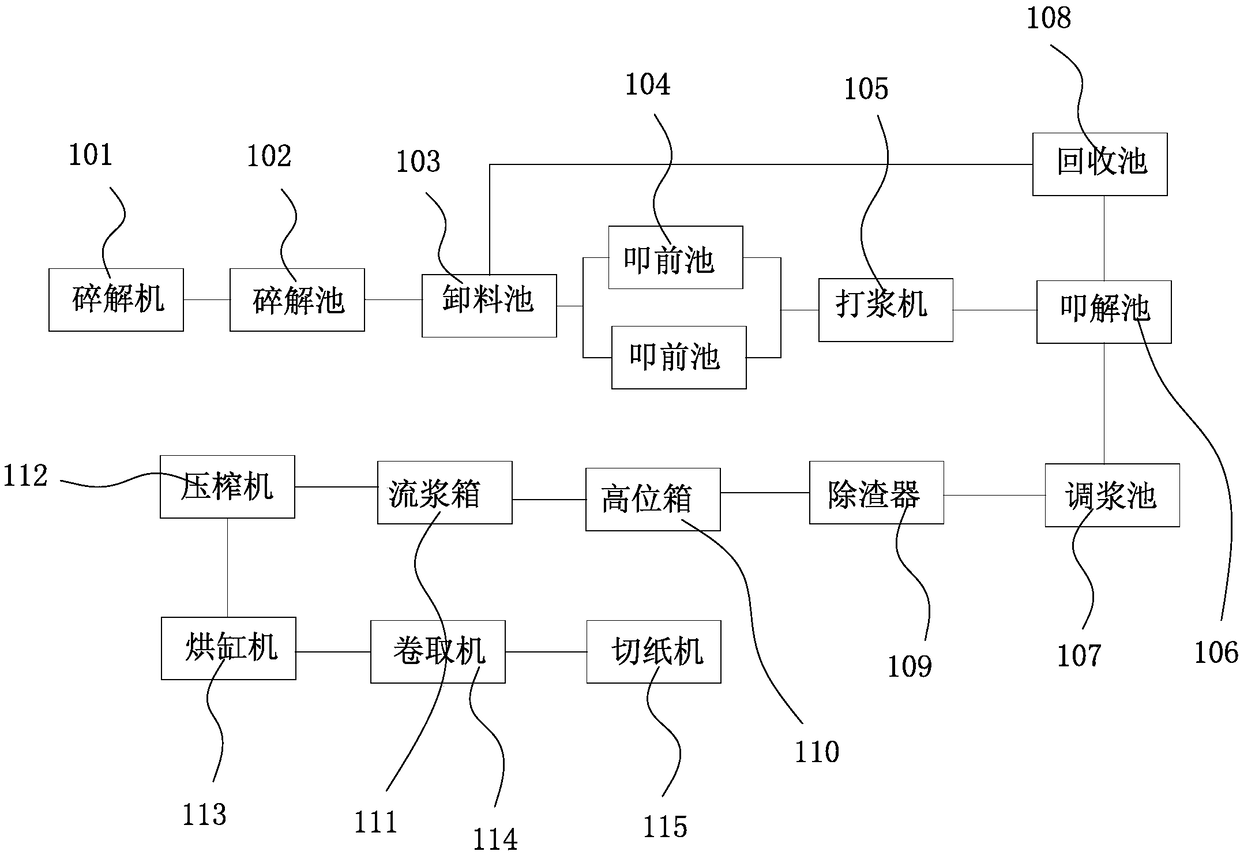

Novel coper paper pulping method

InactiveCN108978319ASave adjustment timeImprove job stabilityPulp beating methodsPaper recyclingWinding machineState of art

The invention relates to the technical field of papermaking, particularly to a novel coper paper pulping method. The novel coper paper pulping method mainly solves the problems in the prior art that instable concentration of disintegrated pulp results in high wearing of a grinding disc of a grinding machine and quality fluctuation ad rejection rate increased of produced paper products impact the overall production efficiency of a paper machine. The novel coper paper pulping method comprises a disintegrating machine, a disintegrating pool, a discharging pool, at least two chest before refiners,a pulping machine, a beating pool, a regulating pool, a recycling pool, a deslagging unit, a high tank, a pulp tank, a press, a dryer, a winding machine and a paper cutting machine.

Owner:福建省晋江优兰发纸业有限公司

Preparation technology for paper for daily use

InactiveCN106835817AIncrease roughnessGood flexibilityNon-macromolecular organic additionReinforcing agents additionEconomic benefitsSlurry

The invention discloses a preparation technology for paper for daily use, belonging to the field of paper-making. The preparation technology comprises the following steps: (1) grinding pulp; (2) preparing a mixed pulp; (3) manufacturing the paper sheet. The paper sheet finally prepared according to the invention is higher in strength and softness; the quality is acquired; the dosage of the added softening agent and dry strength agent is less; the preparation method is reasonable; the whole manufacturing cost is reduced by about 15%; the economic benefit and the market competitiveness of the product are promoted.

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

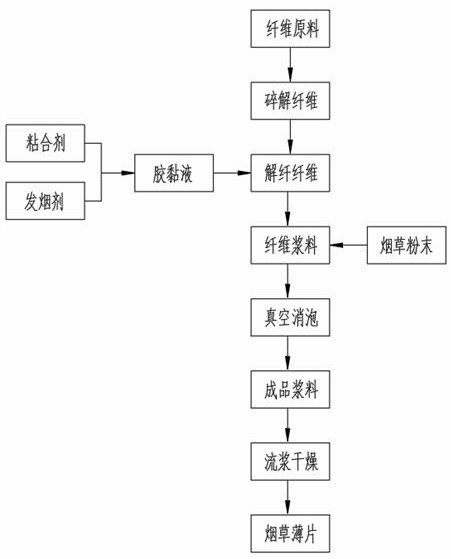

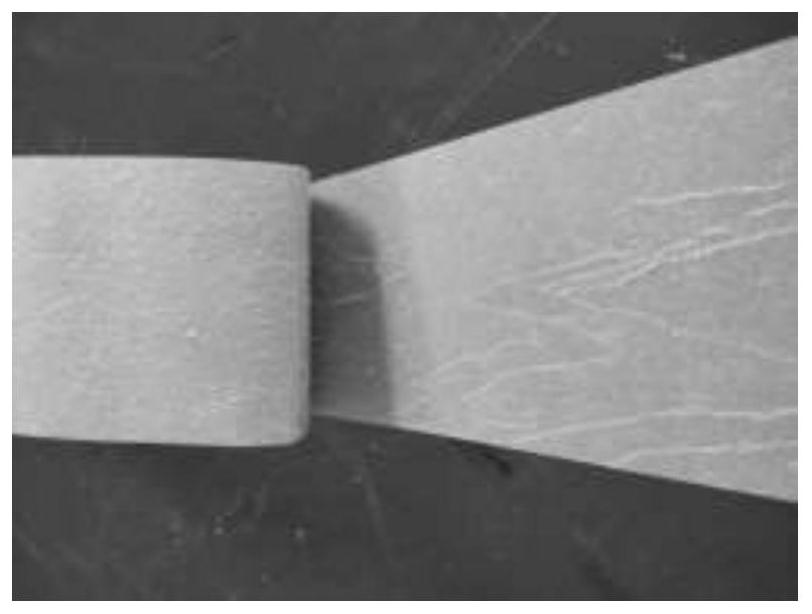

Heat-not-burn tobacco pulp fiber-increasing method

The invention provides a heat-not-burn tobacco pulp fiber-increasing method which comprises the following steps: preparing the following materials, by mass: 60-90% of tobacco powder, 4-12% of fiber raw material, 1-6% of an adhesive and 12-25% of a smoke agent, a total of 100%; by means of fiber raw material repulping, defibrination, fiber raw material splitting, brooming and swelling are facilitated, the hydrogen bond binding force between fibers is increased, the strength and toughness of tobacco sheets are improved, mucilage is added into defibrination pulp, the defibrination pulp can be diluted, fiber dispersion is easier, and due to the fact that the mucilage is very similar to the cellulose molecular structure, the fiber has high affinity, so that the fiber flocculation is prevented effectively; the tobacco powder is added, so that the components are quickly and uniformly mixed, the mixing time of contact between the tobacco powder and water is shortened, tobacco substances are prevented from being changed, and the heat-not-burn tobacco sheet with high strength and good bulk is obtained.

Owner:KUNMING XUBANG MACHINERY

Pulping method applying biological enzyme

InactiveCN107881828APromote swellingReduce cohesionPaper material treatmentPulp treatmentPre treatment

The invention relates to the field of paper making and processing, provides a pulping method applying biological enzymes, which solves the defects that in the prior art a pulping method is high in energy consumption and high in production cost, and paper made by using the pulping method is poor in physical property, limited in enzyme activity site, relatively poor in enzyme activity and relativelyinstable. The pulping method comprises the following steps: (1) preparing pulp, namely mixing needle leaf pulp with broad leaf pulp according to a weight ratio of (6-7):(4-3) so as to obtain mixed pulp; (2) preparing pulping biological enzymes, namely preparing modified biological enzymes,; (3) performing mixing and pre-pulping treatment, namely putting 0.2-0.4kg / ton of the biological enzyme pretreatment mixed pulp modified in the step (2) into a crushing machine, controlling the temperature to 40-50 DEG C, performing reaction for 2 hours, and further pulping in a pulping machine; and (4) performing pulping, wherein the beating degree of the pulp after pulping is 75 degree SR.

Owner:福建希源纸业有限公司

Insulating paperboard production method capable of improving interlayer bonding capacity

ActiveCN113622214ABeat evenlyPromote filamentationPlastic/resin/waxes insulatorsChemical/chemomechanical pulpPaperboardMaterials science

The invention discloses an insulating paperboard production method capable of improving interlayer bonding capacity; which comprises the following steps: by adopting a one-time pulping mode, cutting, extruding, rubbing and rubbing by a pulping machine provided with a double-blocking abrasive disc to obtain pulp, and then dewatering on a net on a super-forming part to obtain a wet paperboard with uniform banner pulp hanging amount; and then allowing the wet paperboard to be subjected to first-stage pressurization and third-stage depressurization, cooling and standing, and finally obtaining the productthrough slitting according to requirements. According to the production method, the problem that in the prior art, interlayer or end cracking is generated when an insulating part product is processed by an insulating paperboard with the thickness of 3.0 mm or above can be solved, the processing performance of the product is improved, and therefore the quality of the product is stabilized.

Owner:WEIFANG HUISHENG INSULATION TECH

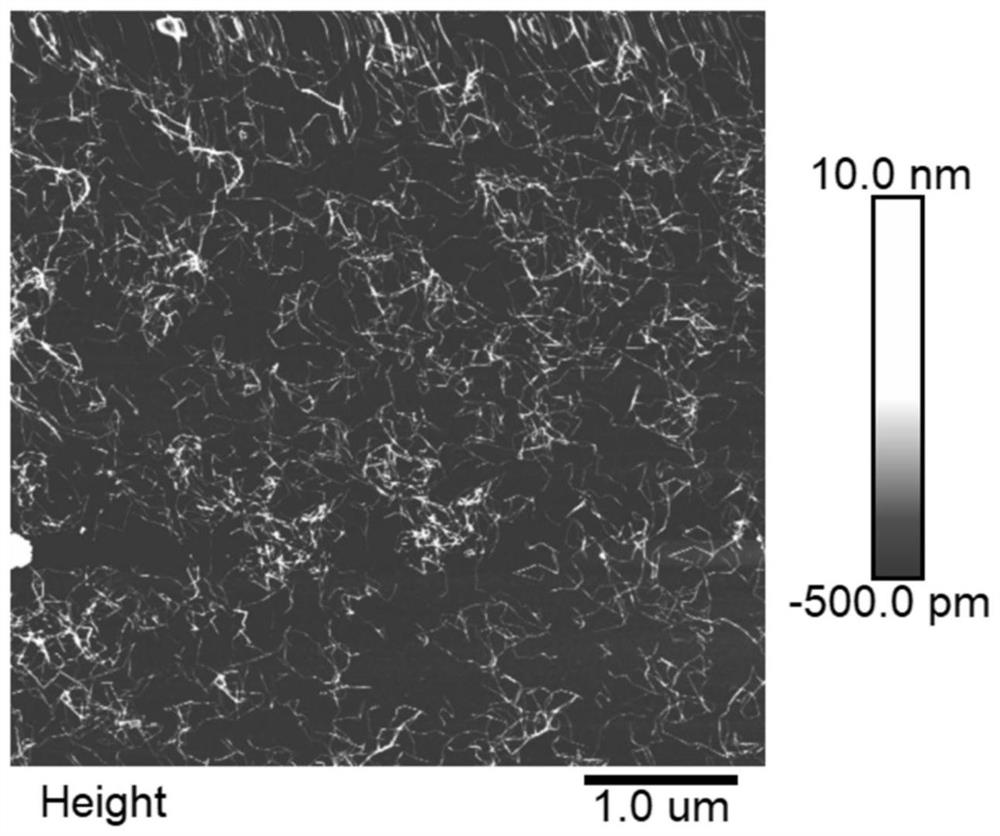

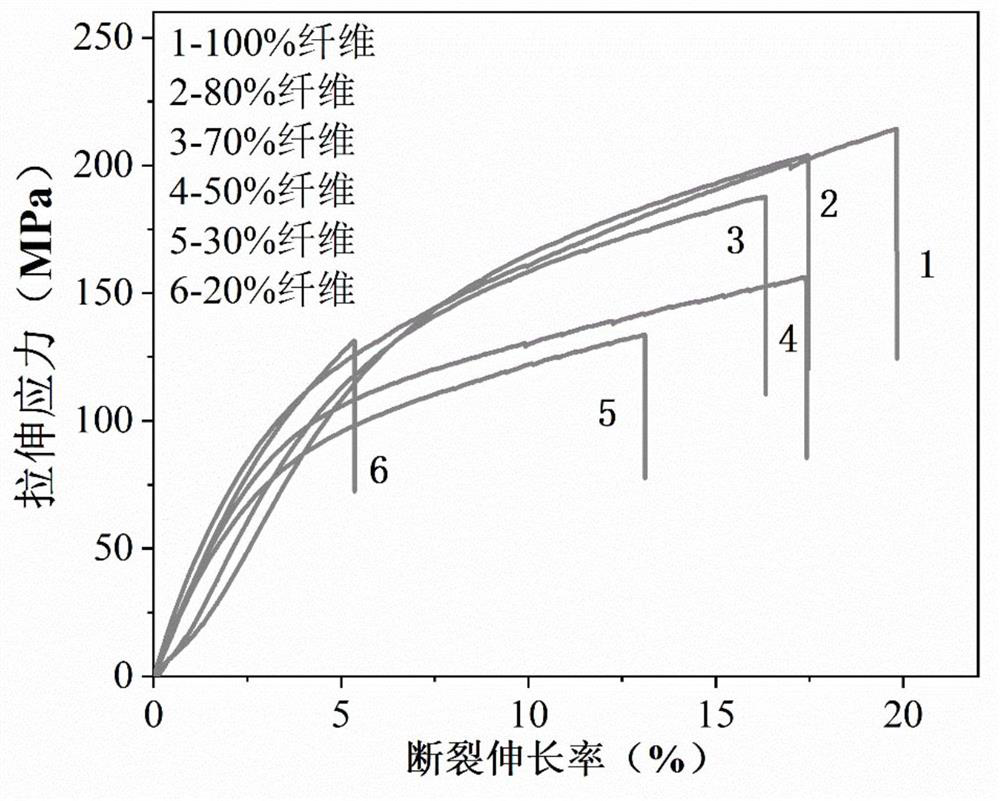

Pineapple leaf fiber reinforced flexible electromagnetic shielding film and preparation method thereof

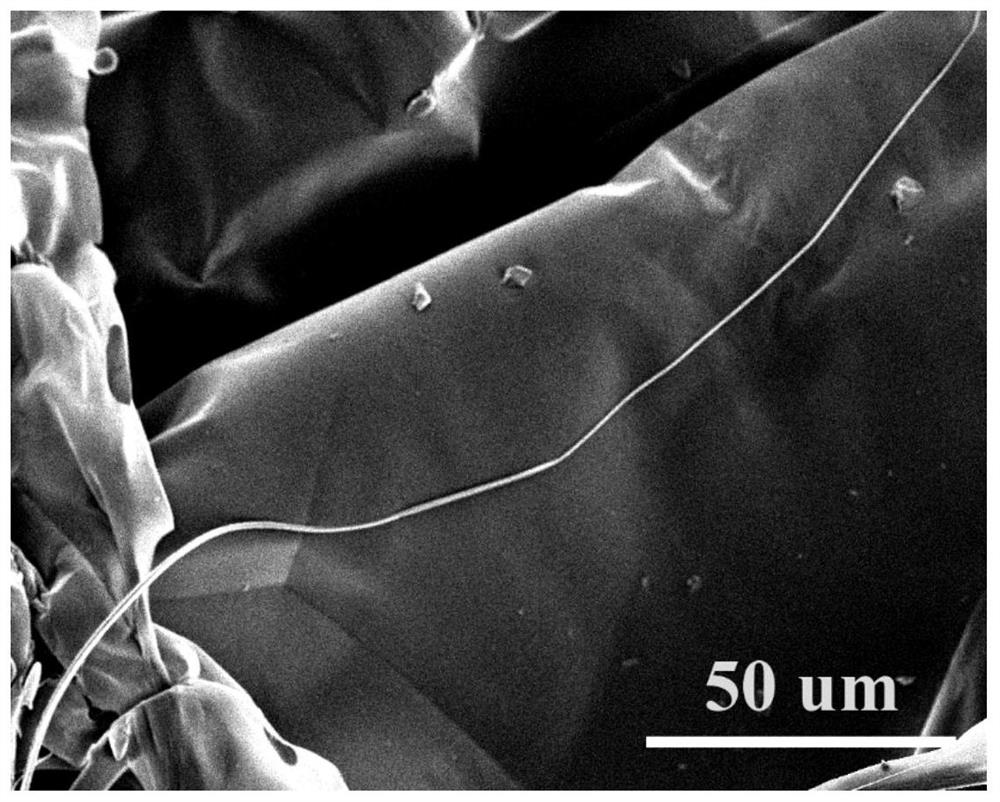

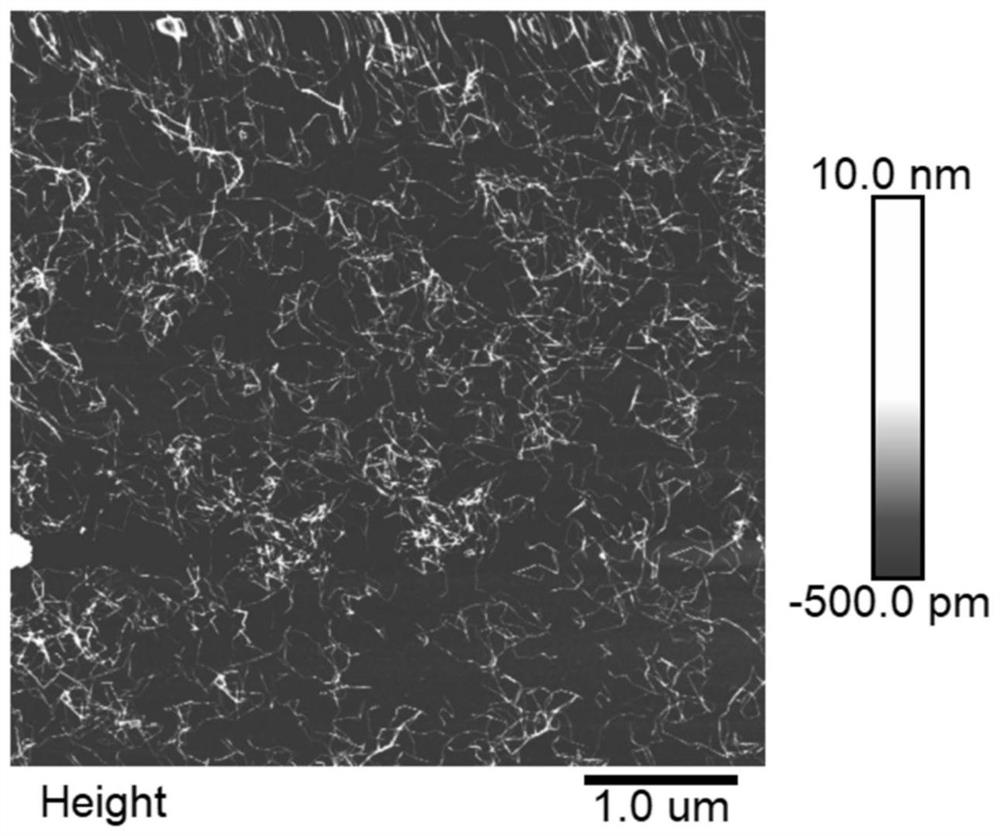

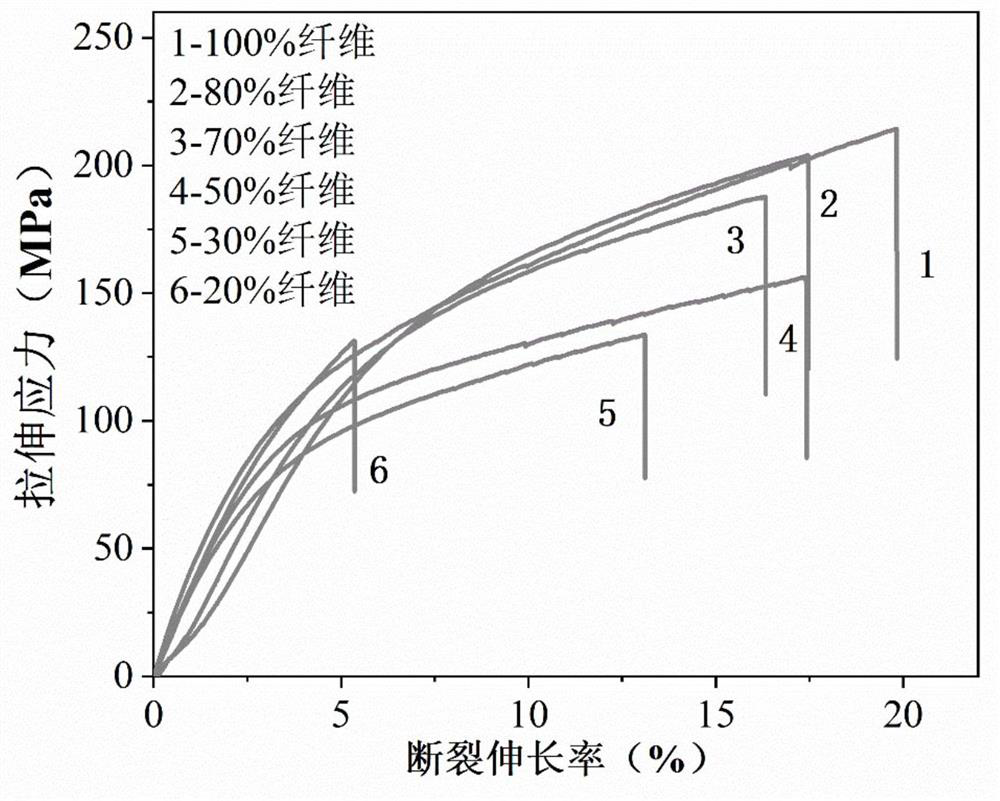

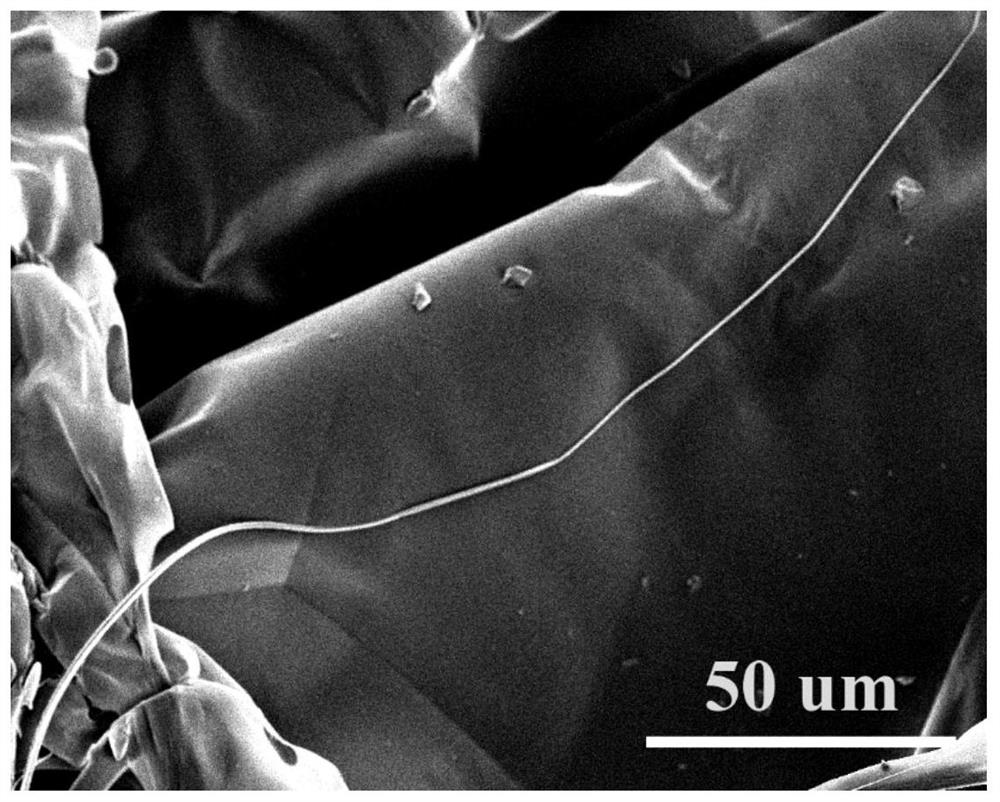

ActiveCN113881108ALow costHigh aspect ratioMagnetic/electric field screeningTransition metal carbidesComposite film

The invention provides an ultrathin, light, flexible, high-strength and high-conductivity pineapple leaf fiber reinforced electromagnetic shielding film and a preparation method thereof. A mechanical interlocking structure is formed by combining high-length-diameter-ratio one-dimensional pineapple leaf micro-nano fibers extracted from whole pineapple leaves with high-conductivity two-dimensional transition metal carbide Ti3C2Tx MXene, the flexibility and mechanical strength of the Ti3C2Tx-based film are improved, meanwhile, the composite film is endowed with excellent conductivity and electromagnetic shielding performance, a new process is provided for application and development of the biomass-based wearable electromagnetic shielding film, and a new way is provided for green and environment-friendly development and recycling and high-value utilization of agricultural by-products.

Owner:SOUTH CHINA UNIV OF TECH

A kind of pineapple leaf fiber reinforced flexible electromagnetic shielding film and preparation method thereof

ActiveCN113881108BLow costHigh aspect ratioMagnetic/electric field screeningTransition metal carbidesComposite film

The invention provides an ultra-thin, light-weight, flexible, high-strength, high-conductivity pineapple leaf fiber-reinforced electromagnetic shielding film and a preparation method thereof. In the present invention, the high aspect ratio one-dimensional pineapple leaf micro- and nanofibers extracted from the whole pineapple leaves are combined with highly conductive two-dimensional transition metal carbide Ti. 3 C 2 T x MXenes combine to form a mechanically interlocked structure to enhance Ti 3 C 2 T x The flexibility and mechanical strength of the base film, and at the same time endow the composite film with excellent electrical conductivity and electromagnetic shielding properties, providing a new process for the application and development of biomass-based wearable electromagnetic shielding films, for the green development of agricultural by-products, and Resource and high-value utilization provides a new way.

Owner:SOUTH CHINA UNIV OF TECH

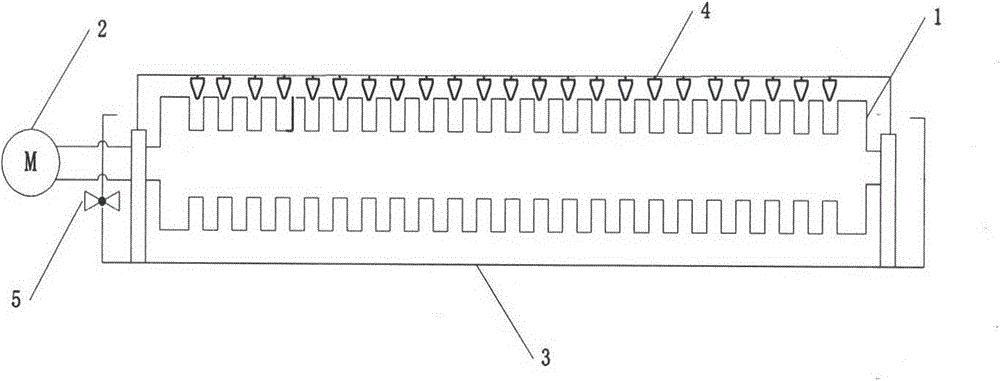

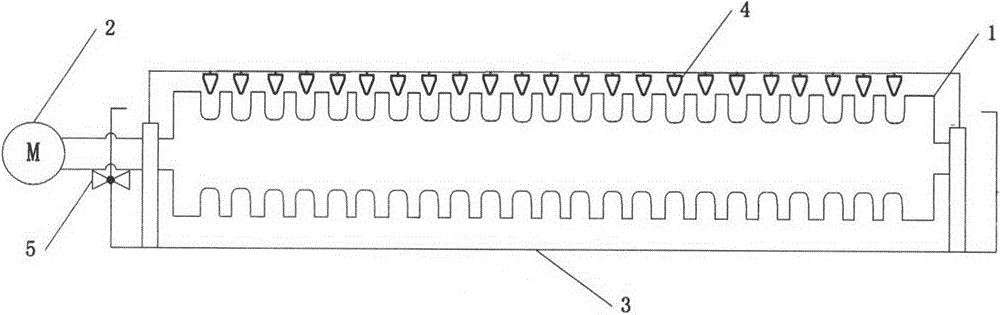

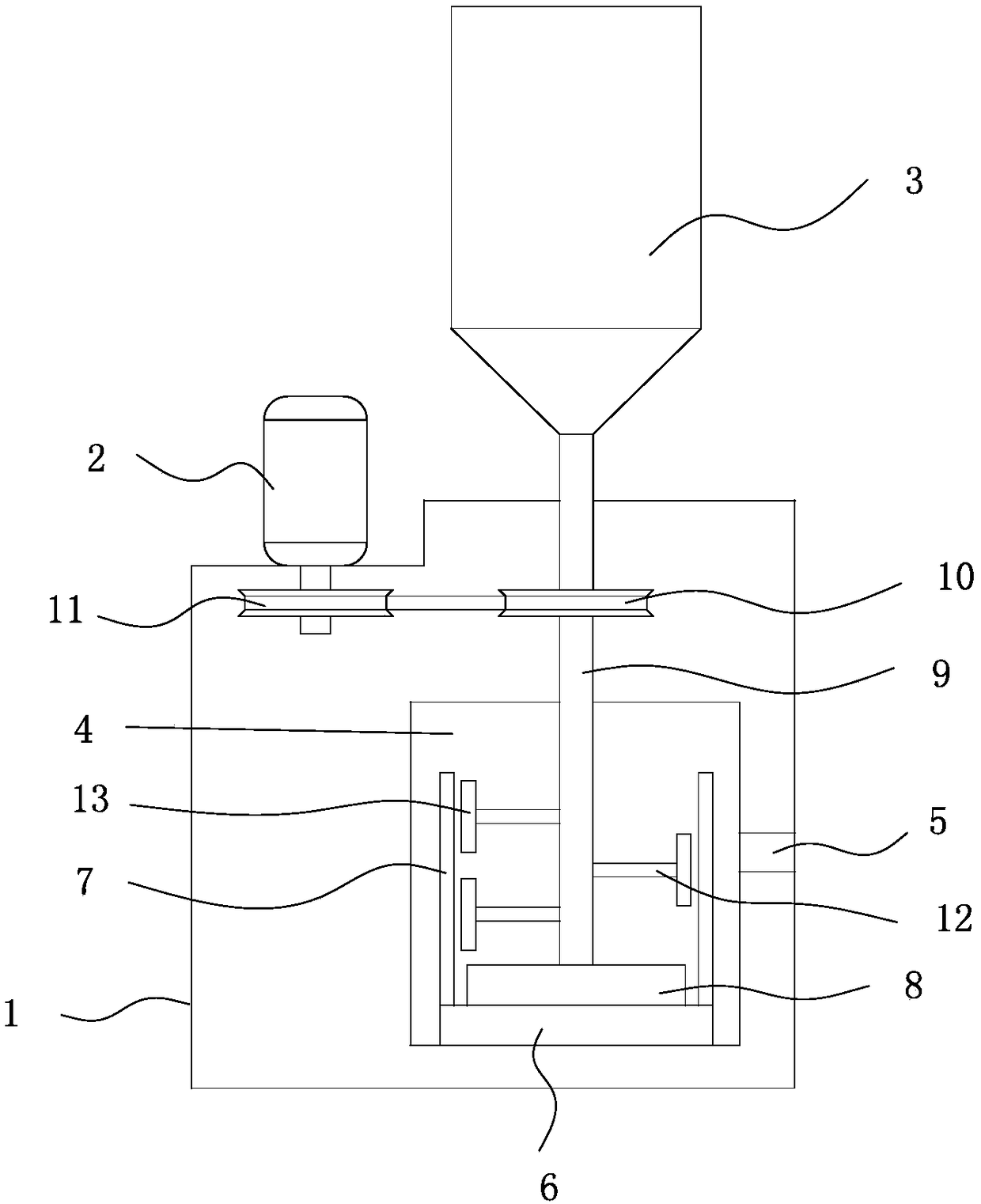

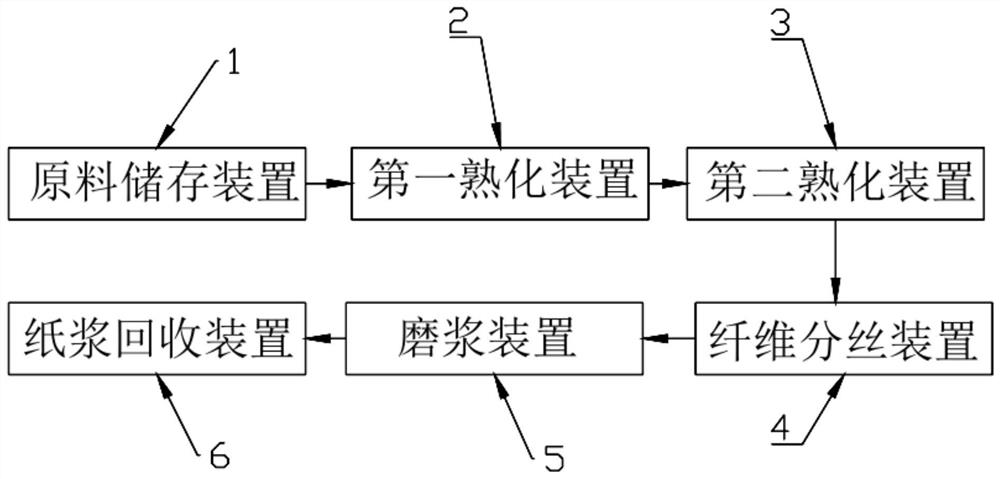

A hard fiber aging system and pulping method thereof

ActiveCN110512453BPromote filamentationFacilitates the ripening processPulp beating/refining methodsMultistage pulping processFiberMaterial storage

The invention relates to the technical field of pulping and papermaking, in particular to a hard fiber aging treatment system and a pulping method thereof. The aging treatment system of the present invention includes a raw material storage device, a first aging device, a fiber separation device, The refining device and the pulp recovery device also include a second aging device, the first curing device is set as a square structure with a cavity inside, and the cross-sectional shape of the first curing device is a right-angled trapezoid with a wide top and a narrow bottom. The invention is equipped with two curing devices, which facilitate better curing of raw materials and subsequent fiber separation. At the same time, by prolonging the curing time, the use of liquid medicine can be reduced, thereby achieving the effect of environmental protection. The pulping method of the present invention includes Material storage, soaking and ripening, vacuum environment ripening, fiber splitting, extruding and separating liquid medicine and pulp collection process are simple and convenient for industrial production. At the same time, the pulping method of the present invention adopts soaking and ripening, which saves cost and is friendly to the environment.

Owner:乐恒香

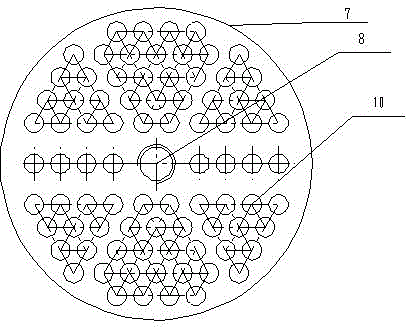

Wire dividing plate of cold cast anchorage and wire dividing method thereof

ActiveCN102747683BReduce manufacturing costExtended service lifeBridge structural detailsBridge erection/assemblyEngineering

The invention provides a wire dividing plate of a cold cast anchorage, which comprises a wire dividing plate main body. The wire dividing plate main body is a plane; a screw hole is arranged at the center of the wire dividing plate; six lines of holes arranged in a straight line and six groups of holes in regular triangle arrangement are evenly distributed along the circumference of the screw hole in a radial manner; and the straight-line holes and the regular triangle hole groups are alternately arranged. The wire dividing method includes the following steps of: bundling semi-parallel steel wires into a regular hexagonal or chamfer hexagonal shape in tight arrangement; in the wire dividing process, inserting an awl along the interlayer of a steel wire bundle, then inserting three rows of thin steel wires with appropriate diameter, wherein the angle between every two rows of thin steel wires is 120degrees; replacing the two thin steel wires at the middle of each row of steel wires with thick steel wires, adjusting the axial positions of the thin and thick steel wires so as to enable the tips of the steel wires to be in arrangement consistent with the holes of the wire dividing plate; buckling the wire dividing plate into the steel wire bundle, jacking the wire dividing plate to an appropriate position through a pipe-jacking for the convenience of upsetting the steel wires, upsetting the steel wires, pulling back the wire dividing plate, and conducting the treatments of sealing, pouring, vibrating and curing. The wire dividing plate has the characteristics of high production efficiency, good anchoring performance and long service life.

Owner:JULI SLING

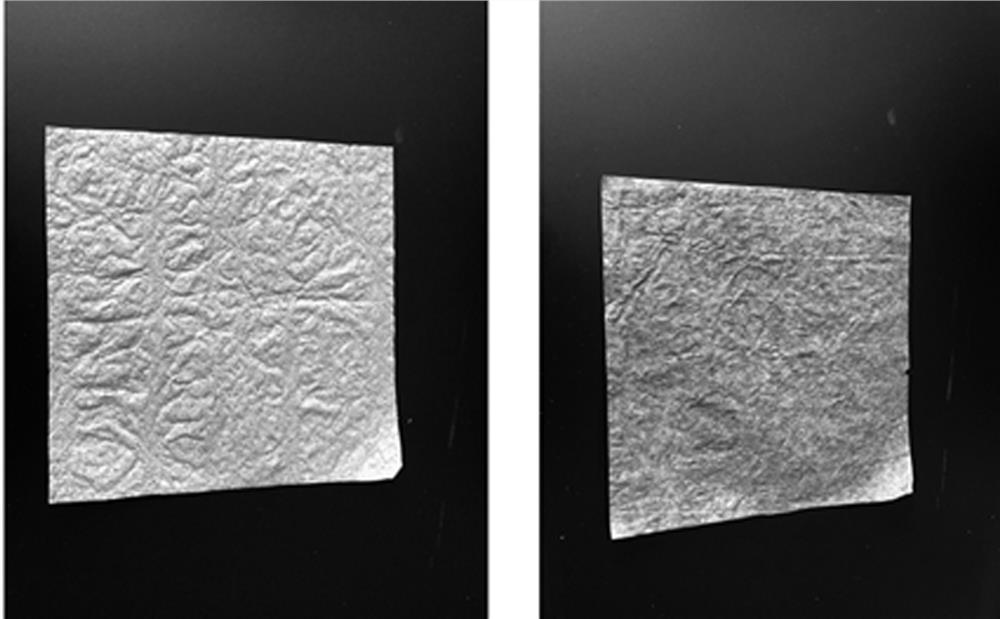

Preparation process of base paper material of high-water-absorption paper towel

ActiveCN114263067AImprove water absorptionConvenient distanceSpecial paperReinforcing agents additionPapermakingPaper towel

The invention relates to the field of paper towel production, in particular to a preparation process of a high-water-absorption paper towel base paper material, which comprises the following steps: repulping: repulping softwood pulp and hardwood pulp, adding chemimechanical pulp at the same time, and adding pulping enzyme when the wood pulp is repulped; slag removal: performing slag removal treatment on the slurry through a slag remover; pulping: conveying the pulp into a pulping machine for pulping; sizing: diluting the slurry with white water, and then feeding the diluted slurry into a sizing system for deslagging and screening; adding chemicals: adding a wet strength agent, a control agent and a bactericide in the sizing process after grinding; papermaking: feeding the screened pulp into a papermaking machine for papermaking to obtain raw paper of the high-water-absorption paper towel; forming on a net: controlling the pulp-net speed ratio to be 0.89-0.94 J / W; drying in a drying cylinder: drying on the surface of the drying cylinder, and uniformly spraying a drying cylinder coating on the surface of the drying cylinder during drying; and wrinkling: wrinkling the paper surface by using a wrinkling scraper. The technical problems that the water absorption performance of the paper towel is poor, and paper is wasted are solved.

Owner:FUJIAN HENGAN HLDG CO LTD +1

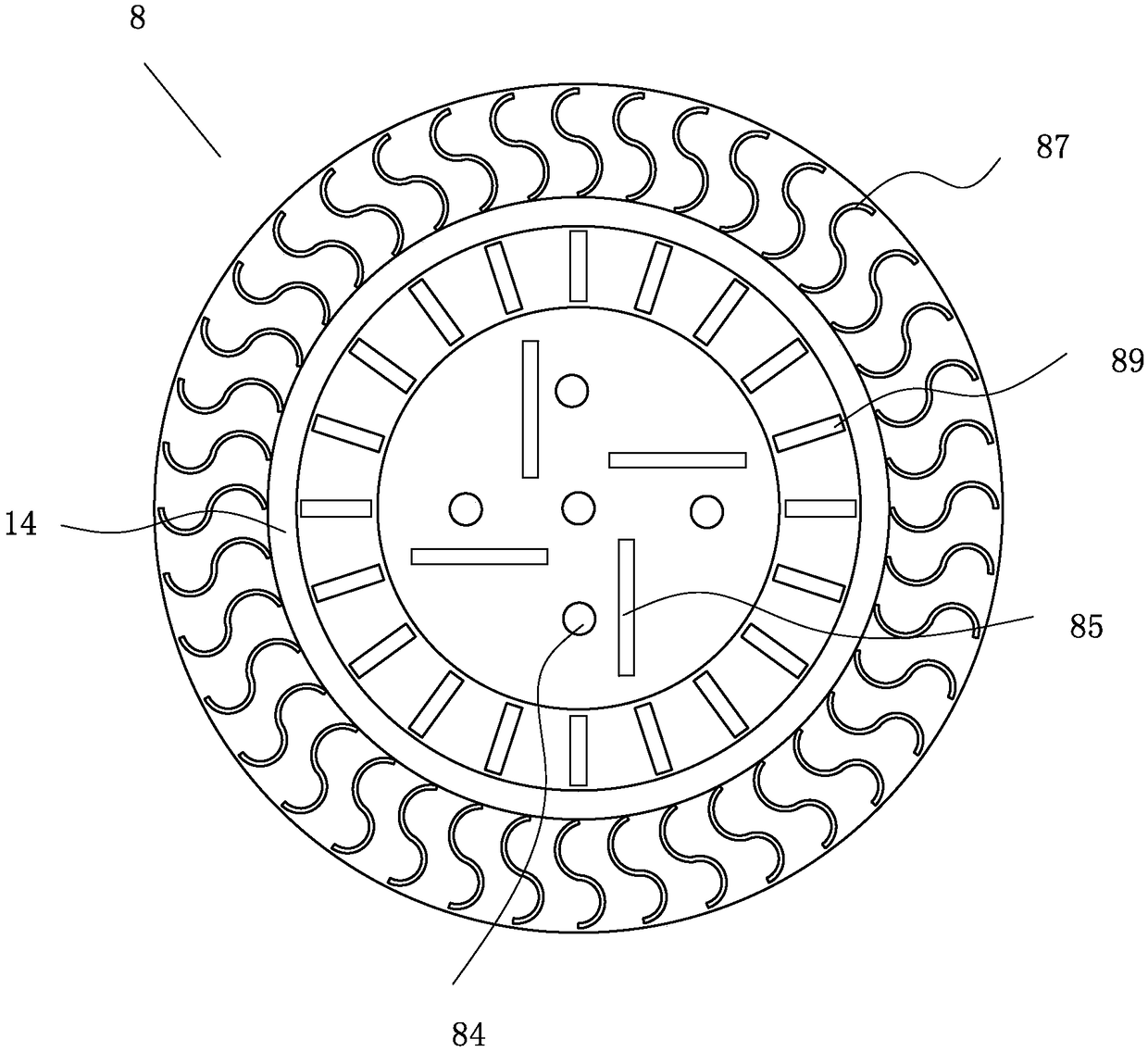

Cylindrical single-grinding grinder

InactiveCN103061190BStable refining performanceHigh strengthPulp beating/refining methodsRadial motionDrive shaft

The invention discloses a cylindrical single-grinding grinder which comprises a frame, a rotor, a shell, a pulp inlet pipe, a pulp outlet pipe and a drive shaft. The drive shaft is connected with a power source. A plurality of movable grinding pieces and a fixed grinding piece are mounted on the outer circumference of the rotor to form a cylindrical grinding area. The fixed grinding piece is connected with a fixed grinding piece moving slider. A slope which can move axially is fixed inside the shell. A sliding plate for converting axial motion into radial motion is disposed between the slope and the fixed grinding piece moving slider. The cylindrical single-grinding grinder further comprises a fixed grinding piece advancing and retreating transmission mechanism. An output end of the fixed grinding piece advancing and retreating transmission mechanism is connected with the shell. The cylindrical single-grinding grinder has the advantages that the cylindrical single-grinding grinder is high grinding quality, stable in grinding state, and high in grinding efficiency compared with traditional dual-disc grinders and conical grinder, pulp performance is improved, and no-load consumption is lowered greatly under the same grinding capacity. In addition, the cylindrical single-grinding grinder is more convenient to operate and evident in economical benefits, the size and the length of the grinder are reduced greatly, and power of matching motors is lowered.

Owner:SUZHOU FEIYU PRECISION TECH

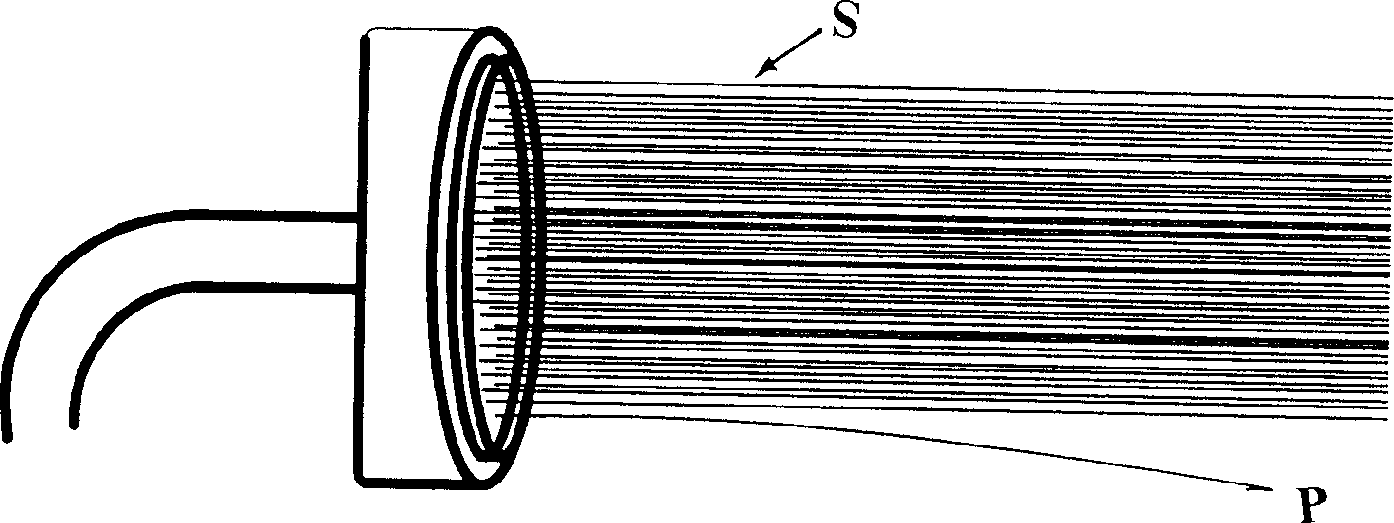

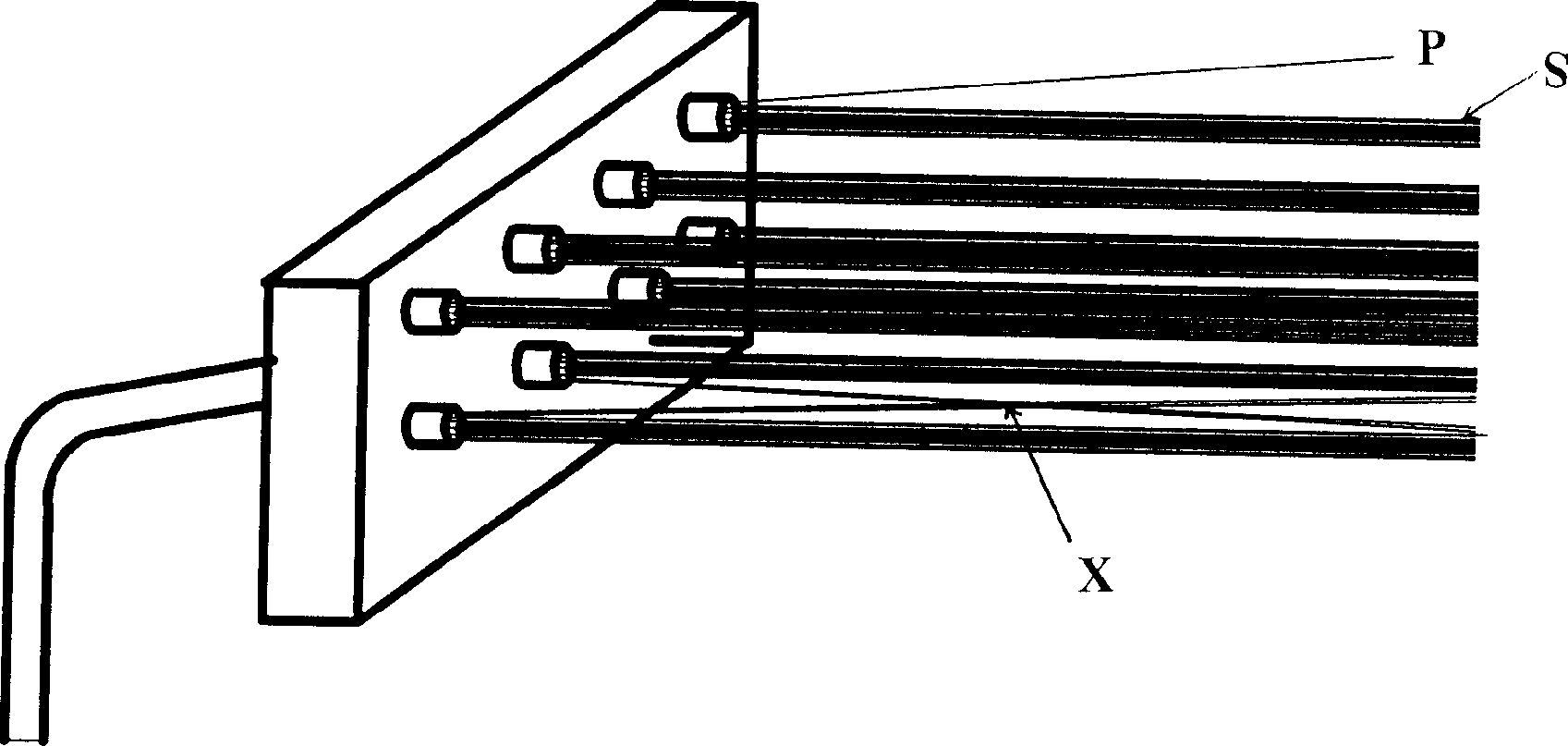

Anchorage and manufacturing process of cfrp tendon stay cable group anchors for bridges

ActiveCN105421231BPromote filamentationGood adhesionBridge structural detailsVibration attenuationMuscle group

The invention discloses a CFRP rib inhaul cable group anchorage device for a bridge. The device comprises an anchor cup, an upper wire separation end plate, a lower wire separation end plate and multiple wire separation partition plates located between the upper wire separation end plate and the lower wire separation end plate are arranged in the anchor cup, the ends of CFRP ribs penetrate through a wire separation vibration attenuation block, the lower wire separation end plate, all the wire separation partition plates and the upper wire separation end plate in sequence from bottom to top and then are fixed to the upper wire separation end plate, the upper wire separation end plate, the lower wire separation end plate and all the wire separation partition plates are each provided with wire separation holes allowing the CFRP rib to pass through, each wire separation hole is internally provided with a gasket, the space formed by the upper end plate, the lower end plate and the inner wall of the anchor cup is divided into multiple filling chambers by the wire separation partition plates, and each filling chamber is filled with rubber mass. According to the CFRP rib inhaul cable group anchorage device, the wire separation end plates and the wire separation partition plates are arranged in the anchor cup, so that wire separation and fixation for the CFRP ribs are facilitated, meanwhile, the anchorage device is separated into the multiple filling chambers, the rubber mass in each filling chamber is made of hard particles with different yields, such as iron sand particles or aluminum oxide particles, rigidity of the rubber mass is adjusted to be increased gradually from the lower end of the anchorage device to the upper end of the anchorage device, the device is adapted to the anchoring loading features of the CFRP ribs, and the anchoring force of the CFRP ribs is raised.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

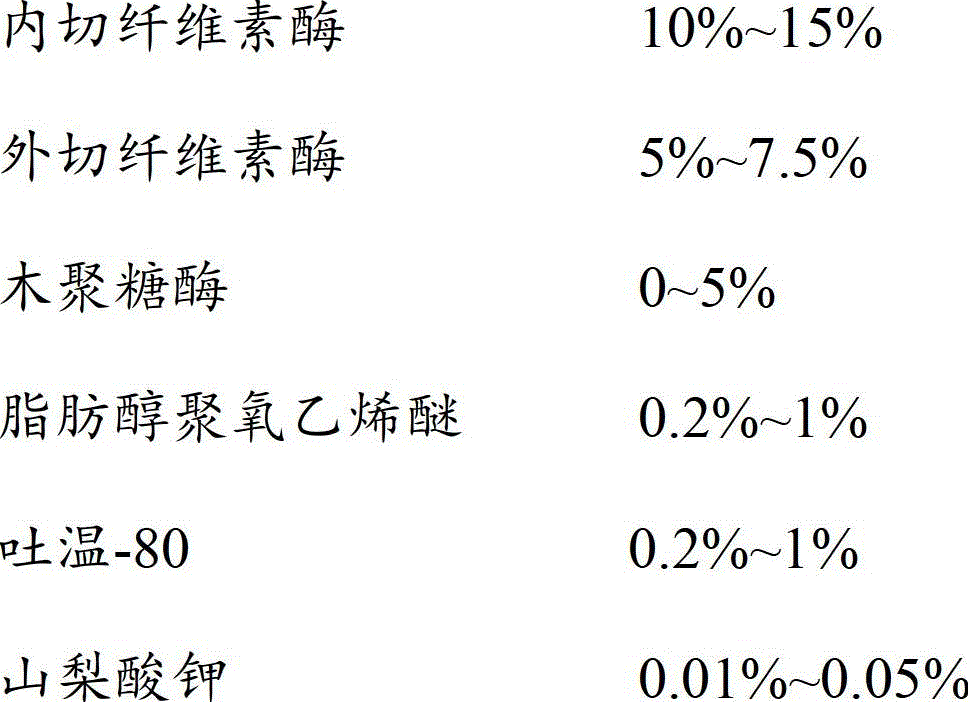

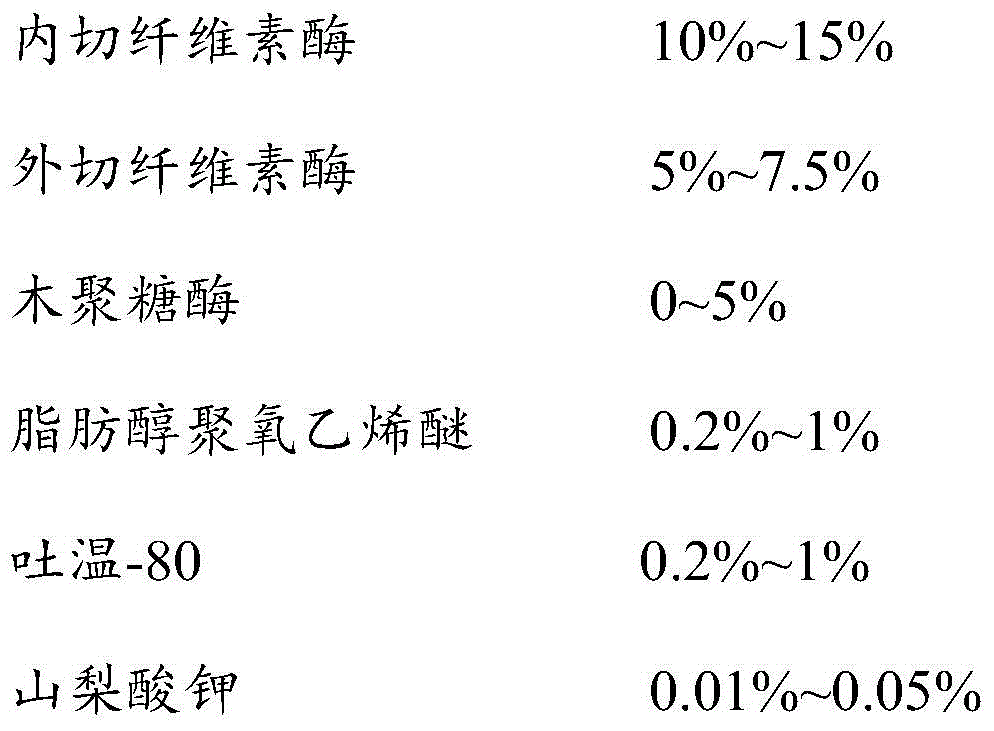

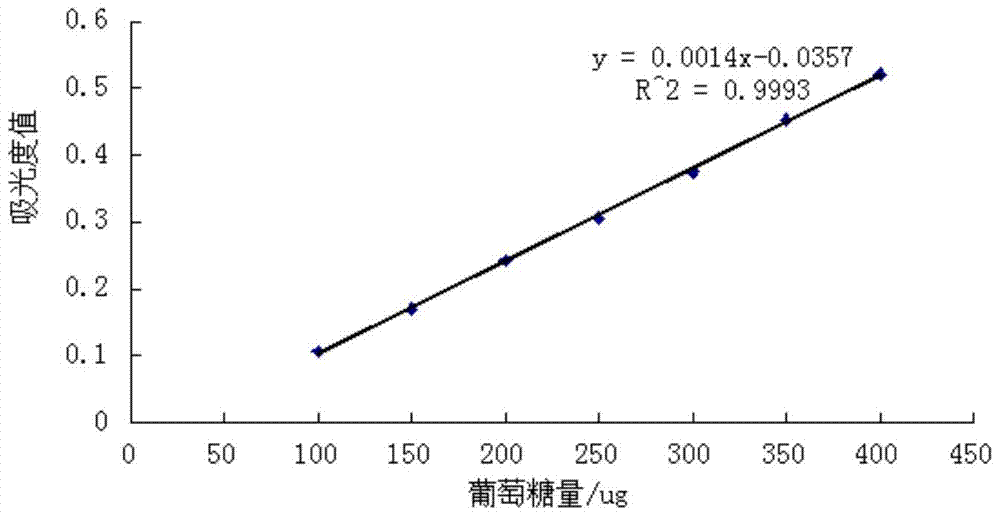

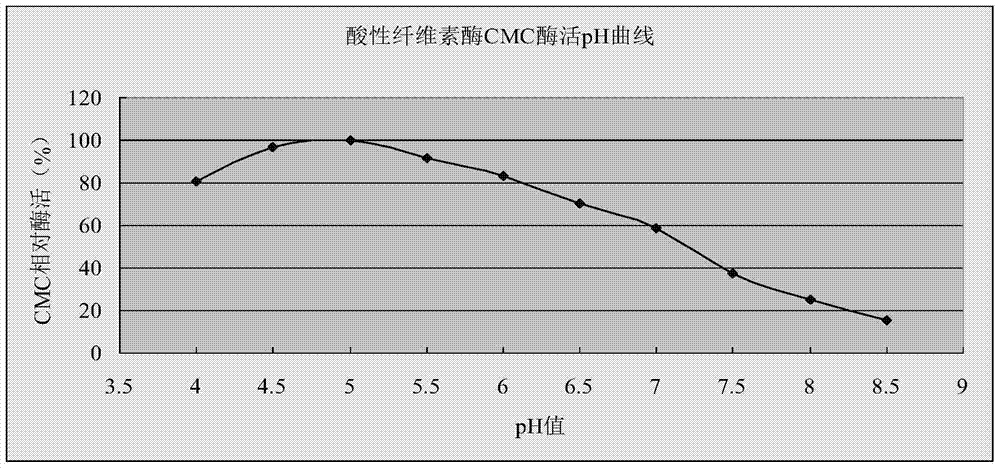

Beating enzyme preparation and its preparation method and application

The invention discloses a beating enzyme preparation, and a preparation method and application thereof. The beating enzyme preparation is prepared from the following components in percentage by weight: 10%-15% of endo-cellulase, 5%-7.5% of cellobiohydrolase, 0-5% of xylanase, 0.2%-1% of fatty alcohol-polyoxyethylene ether, 0.2%-1% of Tween-80, 0.01%-0.05% of potassium sorbate and the balance being deionized water. Due to the synergistic effect of a plurality of enzymes in the beating enzyme preparation, the power consumption of grinding is greatly reduced, a high fibrillation degree of the fiber surface is achieved, the excessive cutting of strong fibers is avoided, a large fiber length is retained and the folding strength and the tearing strength of paper are improved; meanwhile, a fine fiber retention rate can also be effectively improved, and thus the utilization rate of fiber raw materials can be improved.

Owner:ANHUI LEVEKING BIOTECH CO LTD

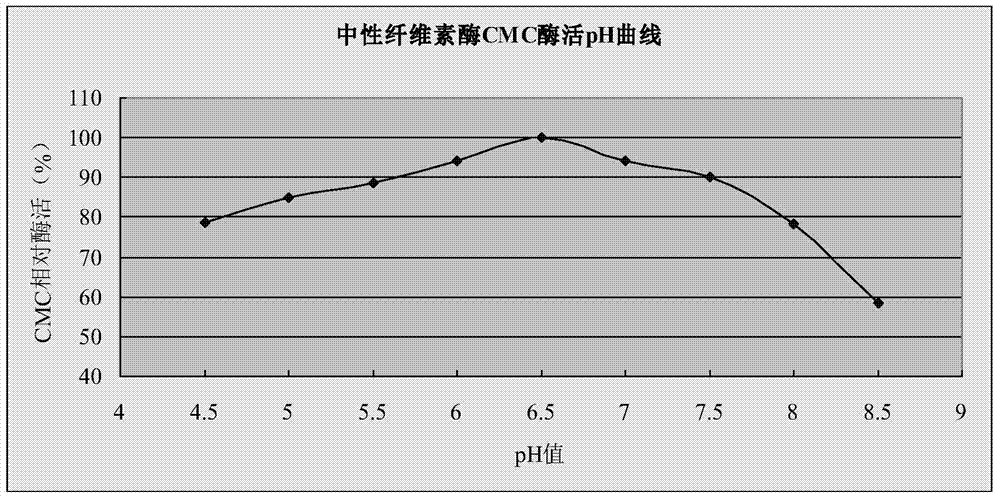

Application of a thermophilic chaetomium cellulase in pulp and papermaking process

ActiveCN105155324BImprove application efficiencyReduce use costEnzymesPaper material treatmentChaetomiumPichia pastoris

The invention discloses application of chaetomium thermophilum cellulase in the pulping and papermaking process. The chaetomium thermophilum cellulase is expressed through trichoderma reesei or pichia pastoris. The chaetomium thermophilum cellulase is neutral cellulase. In the pulping and papermaking process, the optimal effect pH range of the chaetomium thermophilum cellulase is 6.0 to 7.0, and use cost is reduced. The influences of normal fluctuation of the pH of a neutral papermaking system on the chaetomium thermophilum cellulase are low. Frame needle pulp and frame width pulp are pre-treated before pulping of the chaetomium thermophilum cellulase, frame needle pulp and frame width pulp fibers can be modified, and therefore the binding force between the fibers is improved; the interlayer bonding strength of finished paper and the tensile strength are remarkably improved, and the bulkness and stiffness are not obviously changed.

Owner:SHANDONG YOUTELL BIOCHEM +1

Preparation method of soluble polyimide precipitated fiber

ActiveCN107881579BGood dispersionPromote filamentationSynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of soluble and meltable polyimide precipitated fiber, which comprises the following steps: ① mixing calcium chloride, N,N-dimethylacetamide and water in proportion and stirring evenly to obtain Precipitating agent; ②React diamine monomer and dianhydride monomer in an aprotic polar solvent to form a polyamic acid solution, then undergo chemical cyclodehydration to obtain a polyimide solution, and finally dilute to obtain a polyimide Stock solution; ③Inject the precipitating agent and the polyimide stock solution into the precipitator respectively, stir and shear at a high speed in the precipitator to obtain a suspension, and then filter and wash with water to obtain a soluble polyimide precipitator fiber. The polyimide fibrids prepared by the present invention can not only meet the requirements of wet papermaking well, but also can be melted, so that they can be closely combined with polyimide chopped fibers during hot pressing, and finally can be applied to the preparation of High-strength lithium battery separator paper, capacitor paper, insulating paper, honeycomb paper and other high-performance and high-temperature resistant paper products.

Owner:CHANGZHOU SUNCHEM HIGH FORMANCE POLYMER

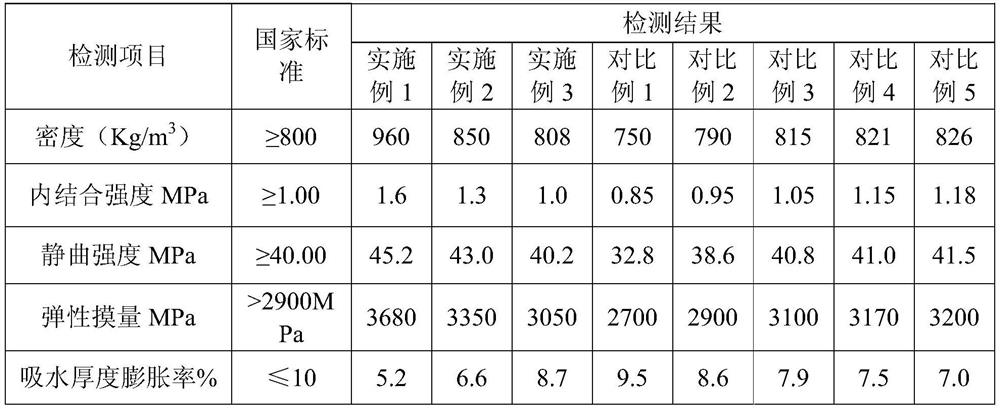

Preparation method of high-density fiberboard

PendingCN113752356AImprove performanceHigh in fiberWood treatment detailsThermal wood treatmentHigh densitySodium hydrogen sulphite

The invention provides a preparation method of a high-density fiberboard, which comprises the following steps: S1, slicing a log material, and adjusting the moisture content of wood chips to 30-40%; S2, primarily softening the wood chips, then cooking and finally carrying out hot grinding, wherein in the primary softening, cellulase and xylanase are adopted for enzymolysis for 2-4 days; in the cooking process, sodium carbonate and sodium hydrogen sulfite accounting for 1-3% of the mass of the wood chips are added into cooking liquor to serve as auxiliaries; S3, carrying out glue mixing and applying procedures on the fibers subjected to hot grinding, and then drying; and S4, carrying out plate blank forming on the dried fibers, and then carrying out plate blank pre-pressing, hot pressing by a hot press and edge cutting to obtain the high-density fiberboard. According to the preparation method, the wood chips are primarily softened through enzymolysis, then the auxiliaries are added for cooking, then hot grinding is conducted, so that the fiber content can be increased, the fiber form and physical performance can be improved, and therefore, the performance of the fiberboard is improved.

Owner:广西上思华林林产工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com