Cylindrical single-grinding grinder

A cylindrical refiner technology, applied in the field of pulp and paper making, can solve the problems of unsatisfactory refining quality and refining efficiency, inconvenient installation, maintenance and operation, uneven refining quality, etc. , to achieve the effects of reduced length and volume, increased effective power, and stable refining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

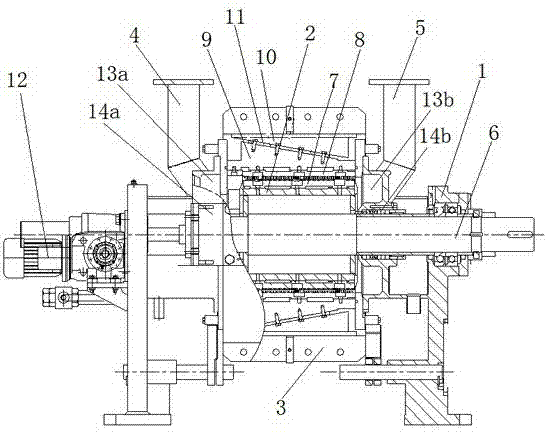

[0029] see figure 1 , The cylindrical single refiner of the present invention includes: a frame 1, a rotor 2, a casing 3, a pulp inlet pipe 4, a pulp outlet pipe 5 and a drive shaft 6 connected to a power source. In order to ensure the performance and quality of pulp, all parts in contact with pulp are made of stainless steel.

[0030] Among them, the frame 1 is used for the support and sealing of the rotor 2 and the discharge of the pulp after refining, and the rotor 2 is used for inputting pulp and transmitting the refining power, and a number of moving grinding plates 7 and fixed grinding plates 8 are installed on its outer peripheral surface To form a cylindrical refining zone. During the refining process, the gap between the fixed grinding plate 8 and the moving grinding plate 7 needs to be adjusted. Therefore, a certain grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com