Cylindrical pulping machine with double pulping areas

A technology of refiner and cylinder, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of unsatisfactory refining quality and refining efficiency of the refining machine, and achieve work Effects of increased load, improved performance, and increased effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

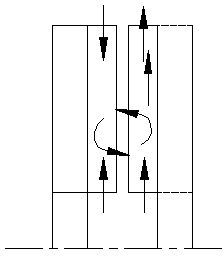

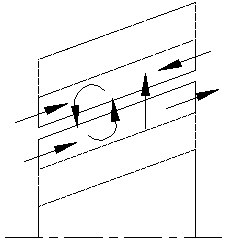

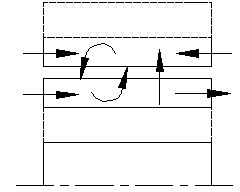

[0032] see Figure 4 , the cylindrical refiner with double grinding area of the present invention comprises: frame 1a, 1b, rotor 2, casing 4, pulp inlet pipe 5, pulp outlet pipe 6a, 6b, drive shaft 7, feed transmission mechanism 8 and grinding mechanism.

[0033] Among them, the frame 1a, 1b is used for the support and sealing of the rotor 2 and the discharge of the pulp after refining, the rotor 2 is used for inputting pulp and transmitting the refining power, and the casing 4 is connected to the output end of the above-mentioned feed transmission mechanism 8, The above-mentioned drive shaft 7 is connected to a motor that provides power; the refining mechanism includes: a number of movable polishing plates 9 mounted on the rotor 2 to form a cylindrical refining zone, an axially moving inclined surface 10 fixedly connected with the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com