Anchorage and manufacturing process of cfrp tendon stay cable group anchors for bridges

A technology for reinforced cable groups and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult CFRP material properties, large thickness of anchor rings, inability to adapt to the characteristics of CFRP reinforcement anchorage, etc., to improve the bonding force. , The effect of preventing shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

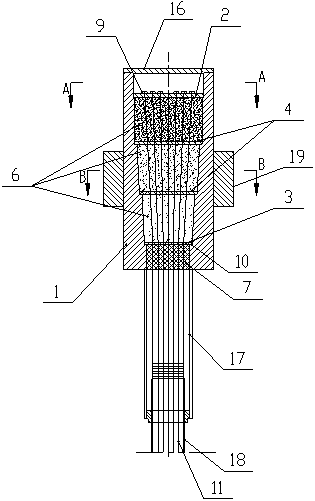

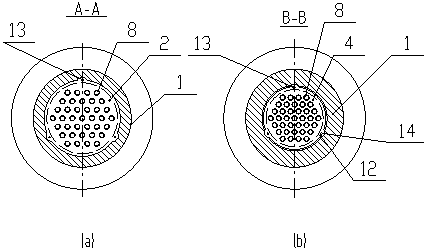

[0037] This embodiment is a CFRP tendon stay cable group anchorage for a bridge, which is respectively installed at both ends of the CFRP tendon stay cable, and the CFRP tendon is anchored by the anchorage. In order to facilitate understanding and description, the anchorage and the corresponding CFRP tendons (the lower length is omitted) are arranged vertically. As shown in the figure, the anchorage includes an anchor cup 1, which has a channel with upper and lower ends open, and the anchor cup A connecting cylinder 17 and a PE protective sleeve 18 are connected below, and a nut 19 is overlaid on the anchor cup 1 . One end of the CFRP tendon 11 passes through the PE protective sleeve 18 and the connecting tube 17 sequentially from bottom to top, and then enters the anchor cup 1, and the CFRP tendon 11 is anchored in the anchor cup 1.

[0038] For the specific anchoring structure of CFRP bar 11, see figure 1 , the channel of the anchor cup 1 is provided with upper and lower sp...

Embodiment 2

[0047] This embodiment is a manufacturing process of a CFRP tendon stay cable group anchor for a bridge, comprising the following steps:

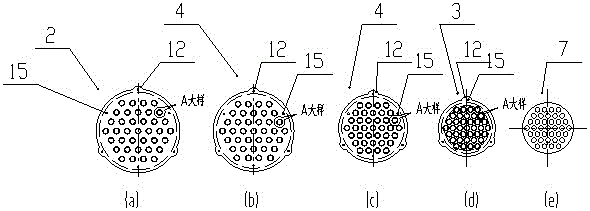

[0048] S1) Prepare anchor cup 1, nut, upper and lower split wire end plates 2, 3, split wire separator 4, split wire vibration damping block 7, washer 8, rubber ring 9 according to size;

[0049] S2) Clamp the anchor cup vertically on the installation platform, according to the length of the anchor cup and the design length of the cable, the CFRP tendon is cut and divided into wires, and a working length of the CFRP tendon is reserved, and the CFRP tendon is penetrated into the divided wire to reduce vibration Block 7, pull and install the split wire damping block 7 and the CFRP tendon to the lower opening of the anchor cup 1, fix the position of the CFRP tendon, and install the lower split wire end plate 3 from the upper mouth of the anchor cup;

[0050] S3) Pour the epoxy resin iron sand mixture from the upper port of the anchor cup 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com