Preparation method of high-density fiberboard

A high-density fiberboard and fiber technology, applied in the field of fiberboard, can solve the problem of high dependence on pine wood, achieve the effects of easy industrial production, improve brittleness, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

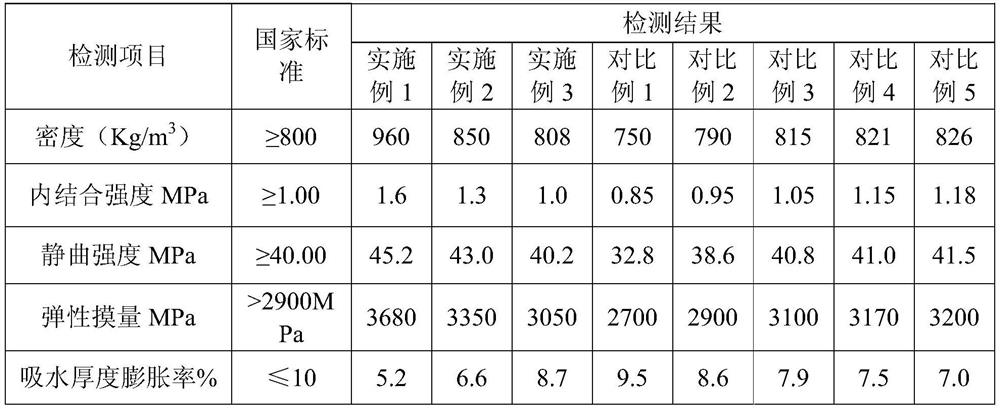

Examples

Embodiment 1

[0028] A preparation method for high-density fiberboard, comprising the following steps:

[0029] S1. Slice the log material, and adjust the moisture content of the wood chips to 30-40%. The slicing process selects pine: eucalyptus = 1:1 as raw material for peeling and slicing.

[0030] S2. Preliminary softening of the wood chips, then cooking, and finally thermal grinding.

[0031] The preliminary softening is enzymatic hydrolysis with cellulase and xylanase for 3 hours. Based on the mass of wood chips, the enzyme dosage of cellulase is 20IU / g, and the dosage of xylanase is 10IU / g. Cellulase and xylanase are mixed, mixed with water at a mass ratio of 1:80-200 to form an enzymolysis solution, and evenly sprayed on wood chips for enzymolysis. The enzymolysis conditions are as follows: the temperature is 30°C.

[0032] During the cooking process, sodium carbonate and sodium bisulfite with 2% mass of wood chips are added to the cooking liquid as auxiliary agents. During the ...

Embodiment 2

[0040] A preparation method for high-density fiberboard, comprising the following steps:

[0041] S1. Slice the log material, and adjust the moisture content of the wood chips to 30-40%. The slicing process selects pine:eucalyptus=1:2 as raw material for peeling and slicing.

[0042] S2. Preliminary softening of the wood chips, then cooking, and finally thermal grinding.

[0043] The preliminary softening is enzymatic hydrolysis with cellulase and xylanase for 3 hours. Based on the mass of wood chips, the enzyme dosage of cellulase is 20IU / g, and the dosage of xylanase is 10IU / g. Cellulase and xylanase are mixed, mixed with water at a mass ratio of 1:80-200 to form an enzymolysis solution, and evenly sprayed on wood chips for enzymolysis. The enzymatic hydrolysis conditions are as follows: the temperature is 30°C.

[0044] During the cooking process, sodium carbonate and sodium bisulfite with 2% mass of wood chips are added to the cooking liquid as auxiliary agents. Durin...

Embodiment 3

[0052] A preparation method for high-density fiberboard, comprising the following steps:

[0053] S1. Slice the log material, and adjust the moisture content of the wood chips to 30-40%. The slicing process selects pine:eucalyptus=1:3 as raw material for peeling and slicing.

[0054] S2. Preliminary softening of the wood chips, then cooking, and finally thermal grinding.

[0055] The preliminary softening is enzymatic hydrolysis with cellulase and xylanase for 3 hours. Based on the mass of wood chips, the enzyme dosage of cellulase is 20IU / g, and the dosage of xylanase is 10IU / g. Cellulase and xylanase are mixed, mixed with water at a mass ratio of 1:80-200 to form an enzymolysis solution, and evenly sprayed on wood chips for enzymolysis. The enzymolysis conditions are as follows: the temperature is 30°C.

[0056] During the cooking process, sodium carbonate and sodium bisulfite with 2% mass of wood chips are added to the cooking liquid as auxiliary agents. During the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com