Heat-not-burn tobacco pulp fiber-increasing method

A heat-not-burn and smoke pulp technology, applied in tobacco, tobacco preparation, application, etc., to achieve the effect of improving quality, strong affinity, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

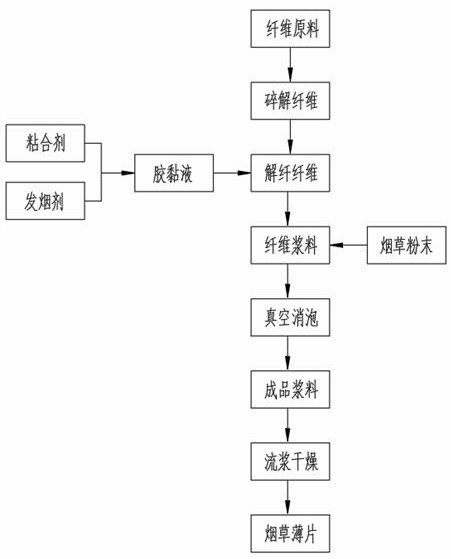

Image

Examples

Embodiment 1

[0040] A method for fiberizing heat-not-burn smoke pulp, comprising the following steps:

[0041] (1) Prepare materials according to the following mass ratios:

[0042] Tobacco powder with a particle size of 80 mesh 60%

[0043] Wood fiber 6%

[0044] Tobacco Fiber 6%

[0045] Guar Gum 3%

[0046] Carboxymethyl Cellulose 3%

[0047] Glycerol 10%

[0048] Ethylene glycol 12%;

[0049] (2) Go through the following steps:

[0050] (21) Feed the fiber raw material into a hydraulic pulper and disintegrate it in an environment with a temperature of 20°C to obtain a disintegrated pulp with a mass concentration of 1%;

[0051] (22) Send the disintegrated pulp in step (21) into a refiner, and perform refining and defibrating at a temperature of 20°C to obtain a degree of disintegration of 80°SR, a fiber length of 0.1-8mm, and a mass concentration of 10% defibrated pulp;

[0052] (23) Mix the adhesive and fuming agent evenly, add water and mix for 10 minutes at a temperature of...

Embodiment 2

[0058] A method for fiberizing heat-not-burn smoke pulp, comprising the following steps:

[0059] (1) Prepare materials according to the following mass ratios:

[0060] Tobacco powder with particle size of 100 mesh 82%

[0061] Bamboo fiber 1%

[0062] Sugarcane Fiber 2%

[0063] Tobacco Fiber 1%

[0064] Chitosan 2%

[0065] Propylene Glycol 6%

[0066] Sorbitol 6%;

[0067] (2) Go through the following steps:

[0068] (21) Feed the fiber raw material into a hydraulic pulper and disintegrate it in an environment with a temperature of 50°C to obtain a disintegrated pulp with a mass concentration of 1%;

[0069] (22) Feed the disintegrated pulp in step (21) into a refiner, and refine and defibrate in an environment with a temperature of 50°C to obtain a degree of disintegration of 90°SR, a fiber length of 0.1-8mm, and a mass concentration of 8% defibrillation pulp;

[0070] (23) Mix the adhesive and fuming agent evenly, add water and mix for 50 minutes at 40°C to make ...

Embodiment 3

[0076] A method for fiberizing heat-not-burn smoke pulp, comprising the following steps:

[0077] (1) Prepare materials according to the following mass ratios:

[0078] Tobacco powder with a particle size of 200 mesh 70%

[0079] Hemp fiber 3%

[0080] Straw Fiber 7%

[0081] Konjac Gum 2%

[0082] Carboxymethylcellulose 2%

[0083] Butanediol 8%

[0084] Ethylene glycol 8%;

[0085] (2) Go through the following steps:

[0086] (21) Feed the fiber raw material into a hydraulic pulper and disintegrate it in an environment with a temperature of 30°C to obtain a disintegrated pulp with a mass concentration of 1%;

[0087] (22) Send the disintegrated pulp in step (21) into a refiner, and perform refining and defibrating at a temperature of 30°C to obtain a degree of disintegration of 70°SR, a fiber length of 0.1-8mm, and a mass concentration of 5% defibrillation pulp;

[0088] (23) Mix the adhesive and the fuming agent evenly, add water and mix for 40 minutes at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com