Wire dividing plate of cold cast anchorage and wire dividing method thereof

A technology of cold casting anchors and wire splitters, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of increasing the amount of cold casting materials and sealing materials, extending sealing sleeves, and high strength of steel wires, so as to improve Effects of injection rate, shortened length, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

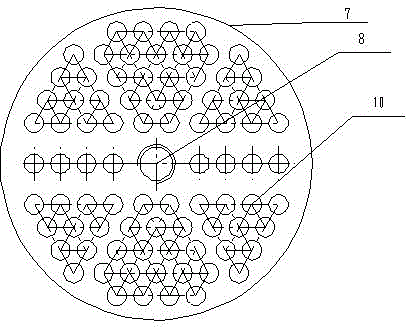

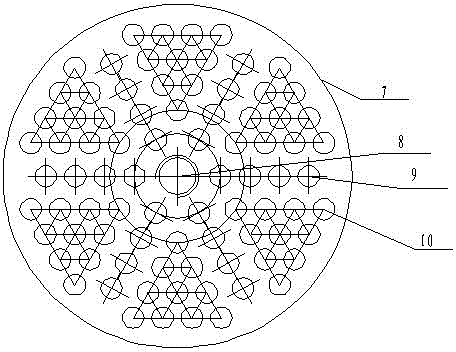

[0022] like figure 2 As shown, the splitter plate of the cold-cast anchor includes the splitter plate 7 as a plane, and the center of the splitter plate 7 is provided with a threaded hole 8, and the periphery of the threaded hole 8 is evenly distributed with six rows of inline holes 9 and six Some of the holes 10 arranged in a regular triangle, the holes arranged in a straight line and the holes arranged in a regular triangle are alternately arranged. According to the arrangement and distribution of the steel wires of the cable body, the number of holes arranged in-line in each row is at least 2, and the number of holes in the in-line arrangement in each row is at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com