Preparation process of base paper material of high-water-absorption paper towel

A preparation process and paper towel technology, which is applied in the fields of special paper, fiber raw material processing, natural cellulose pulp/paper, etc., can solve the problems of poor water absorption performance of paper towels, paper waste, etc., to save energy consumption for beating and improve fiber separation The effect of brooming and improving paper tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

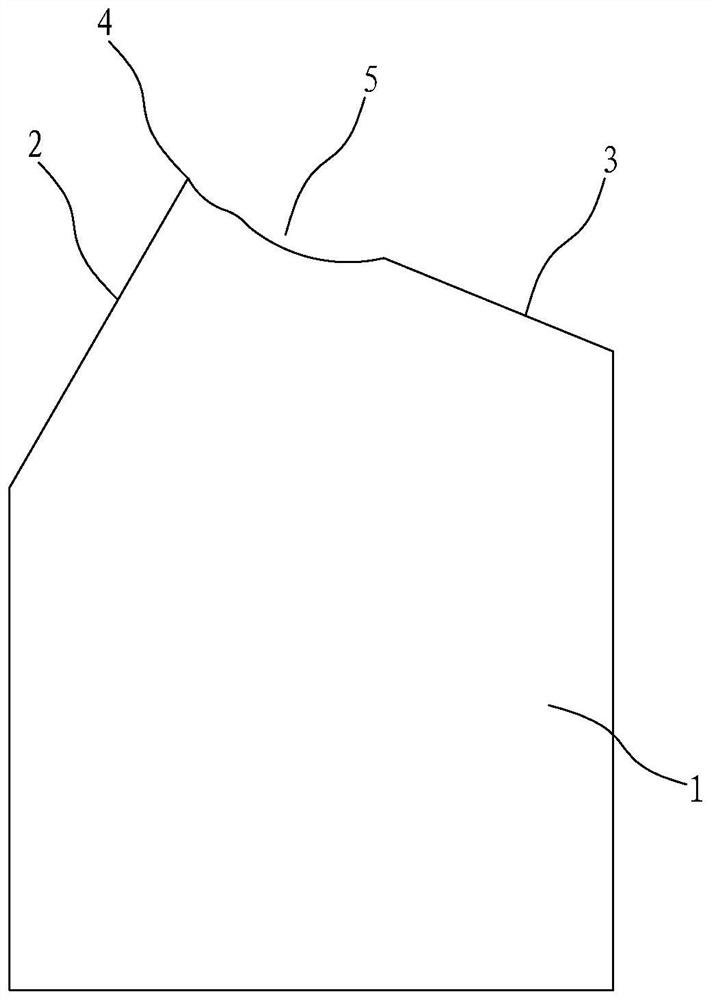

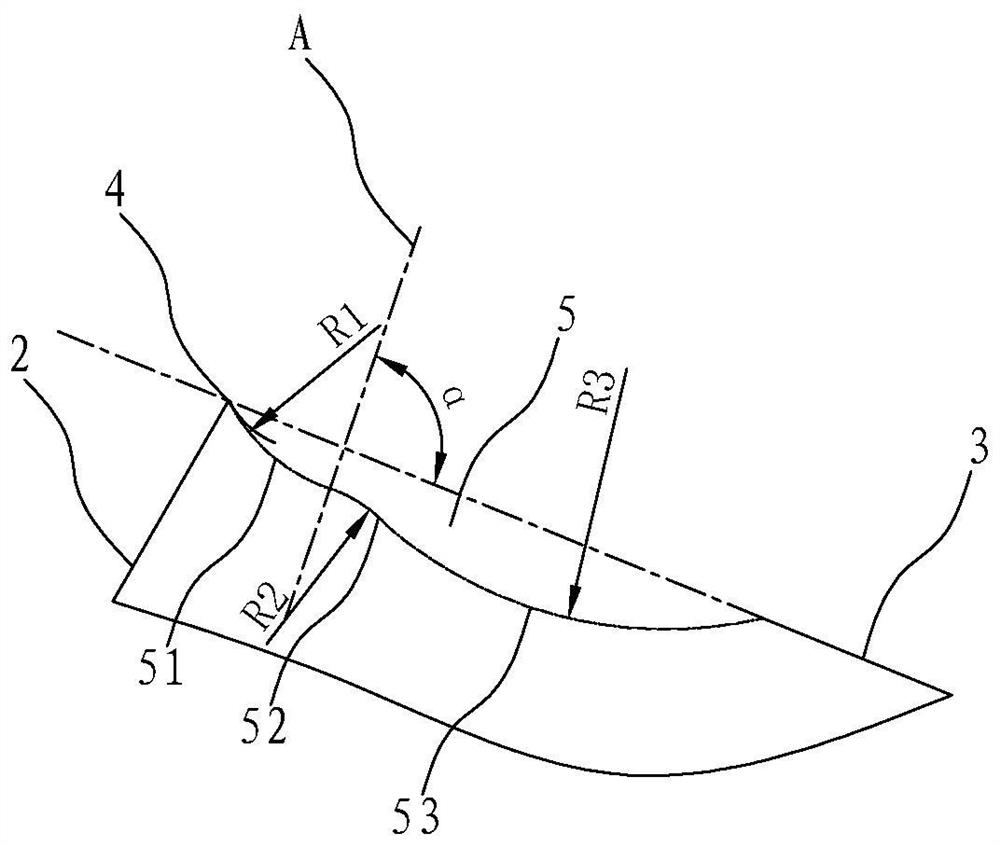

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0029] This embodiment provides a preparation process for a base paper material for superabsorbent paper towels, comprising the following steps:

[0030] The first step, pulping: Put the softwood pulp and hardwood pulp into the hydropulper for crushing, and add chemical mechanical pulp at the same time to improve the paper tightness and supplement the long fiber content, and add beating enzyme when the wood pulp is crushed ;

[0031] The second step, slag removal: the disintegrated slurry is deslagging through a slag remover to remove coarse and heavy impurities to prevent abrasion of the refiner or residues entering into paper;

[0032] The third step, refining: transport the pulp after deslagging to the refiner for refining, and the refining power is 20-40kwh / t pulp;

[0033] The fourth step, sizing: the slurry is diluted with white water, enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com